10

8.

Misalignment will show up as a gap between the pulley face and straight edge.

Make sure there is clearance between arbor pulley and saw base on both sides.

DRY CUTTING

• Never operate any saw without safety guards in place.

•

Do not exceed maximum operating speed established for blade diameter.

•

Do not force blade into material: allow blade to cutat Its own speed.

•

Do not make long continuous cuts. Never dry cut for more than 30 seconds

at s time. Allow blade to cool.

•

Do not cut or grind with side of blade or cut a curve or radius. Do not cut dry

with blades recommended for wet cutting.

•

Do not operate saw with blade diameter larger than machine’s capacity.

IV LUBRICATION AND SERVICE

•

Check oil levels, wiring, hoses (air, fuel, water) and lubricate machine daily.

•

Repair or replace all worn or damaged components immediately.

•

Check drive belt tension, do not over-tension.

•

Make sure machine has full set of matched belts.

•

Check blade shaft, make sure arbor and threads are not worn, damaged, or

bent.

•

Blade shaft bearings should be tight, no free play side-to-side or up and down.

•

Grease blade shaft bearings daily.

•

Blade collars should be clean, free of nicks and burrs. No diameter wear and not

out of round.

•

Drive pin not excessively worn or bent and free of gouges.

•

All guards in place and secure.

•

All fasteners tight and secure.

•

Air filter/oil filter (hydraulic or engine)clean.

•

Flush clean water through the pump and spray the assembly every night. This

prolongs the pump and blade life.

These products are covered by warranty for a period of six (6) months from the date of

purchase against defects in material or workmanship provided that:

•

The product concerned has been operated and maintained in accordance with

the operating instructions.

•

Has not been damaged by accident, misuse or abuse.

•

Has not been tampered with or repaired by any unauthorized person.

The owner is responsible for the cost of transportation to and from the authorized

repairer and the unit is at the owners risk while in transit to and from the repairer.

Lubricants:

-

Engine oil SAE 10W/30

-

General Grease #1 Lithium

Summary of Contents for BSC350

Page 1: ...EN RU 01 2014 www helmutworld com support CONCRETE CUTTER BSC350 BSC350H...

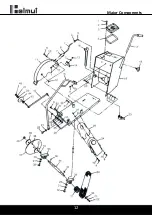

Page 12: ...12 Major Components...

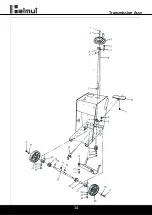

Page 14: ...14 Transmission Assy...

Page 16: ...16 Depth Adjusting Assy...

Page 18: ...18 Engine Assy...

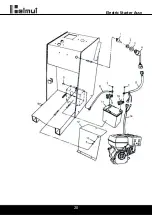

Page 20: ...20 Electric Starter Assy...

Page 22: ...22 4 1 BSC300H BSC300 300 350 80 83 5 5 5 3600 3800 0 9 Honda GX 160 Standart 850 520 1000...

Page 23: ...23...

Page 24: ...24 92 4 10 25 4 22 32...

Page 25: ...25 20 9 5 1200 3 1 2 5 4 6...

Page 26: ...26 2 SAE 15W40 92...

Page 27: ...27 8 10 98 10 0 8 1...

Page 28: ......