3

1 RULES FOR SAFE OPERATION WARNING:

Failure to follow instructions in this manual may lead to serious injury or even death! This

equipment is to be operated by trained and qualified personnel only! This equipment is

for industrial use only.

The following safety guidelines should always be used when operating these Concrete

Cutters:

GENERAL SAFETY

■

DO NOT operate or service this equipment before reading the entire manual.

■

This equipment should not be operated by persons under 18 years of age.

■

NEVER operate this equipment without proper protective clothing. Shatterproof

glasses, steel-toed boots and other protective devices required by the job.

■

NEVER operate this equipment when not feeling well

due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not recommended by our

company for this equipment . Damage to the equipment and/or injury to user may result.

■

The manufacturer does not assume responsibility for any accident due to

equipment modifications.

■

Whenever necessary, replace nameplate, operation and safety decals when

they become difficult to read.

■

ALWAYS check the machine for loosened threads or bolts before starting.

■

NEVER touch the hot exhaust manifold, muffler or cylinder. Allow these parts to

cool before servicing engine or saw.

■

High Temperatures - Allow the engine to cool before adding fuel or performing

service and maintenance functions. Contact with hot components can cause serous

bums.

■

The engine section of this cutter requires an adequate free flow of cooling air.

NEVER operate the cutter in any enclosed or narrow area where free flow of the air is

restricted . If the air flow is restricted it will cause serious damage to the saw or engine

and may cause injury to people . Remember the cutter’s engine gives off DEADLY carbon

monoxide gas.

■

ALWAYS refuel in a well-ventilated area, away from sparks and open flames.

■

ALWAYS use extreme caution when working with flammable liquids. When

refueling, stop the engine and allow it to cool. DO NOT smoke around or near the

machine. Fire or explosion could result from fuel vapors, or if fuel is spilled on a hot

engine.

■

NEVER operate the cutter in an explosive atmosphere or near combustible

materials. An explosion or fire could result causing severe bodily harm or even death.

■

Topping-off to the fuel filler port is dangerous, as it tends to spill fuel.

■

NEVER use fuel as a cleaning agent.

Summary of Contents for BSC350

Page 1: ...EN RU 01 2014 www helmutworld com support CONCRETE CUTTER BSC350 BSC350H...

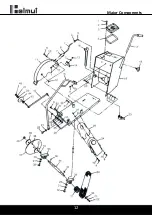

Page 12: ...12 Major Components...

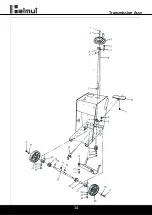

Page 14: ...14 Transmission Assy...

Page 16: ...16 Depth Adjusting Assy...

Page 18: ...18 Engine Assy...

Page 20: ...20 Electric Starter Assy...

Page 22: ...22 4 1 BSC300H BSC300 300 350 80 83 5 5 5 3600 3800 0 9 Honda GX 160 Standart 850 520 1000...

Page 23: ...23...

Page 24: ...24 92 4 10 25 4 22 32...

Page 25: ...25 20 9 5 1200 3 1 2 5 4 6...

Page 26: ...26 2 SAE 15W40 92...

Page 27: ...27 8 10 98 10 0 8 1...

Page 28: ......