6

OPERATION

Introduction/Determining the Right Machine

Congratulations on your pumhase of our Cutter! You’ve made an excellent choice! Our

floor cutter has been specifically designed as the ideal machine for the professional

contractor who is engaged in concrete and asphalt flat sawing.

The machines used for the primary purpose of 'flat” sawing. This type of sawing is

described as “flat” because the pavement is cut somewhere close to a horizontal plane. It

is the most common type of diamond blade cutting.

Concrete cutters in the industry are available in a variety of types, sizes and styles, they

range from manual or self propelled in horsepower Ют 7-72hp. It is possible to cut both

concrete (green or cured, with or without rebar) or asphalt with a concrete cutter. Our

MF20 utilized for jobs requiring precision cutting including floors, pavements, walkways,

ramps and other flat sawing applications.

You will find a cutter to fit a wide vanety of job applications.

Upon receipt of your machine, CAREFULLY CHECK FOR ANY FREIGHT DAMAGE. Any

Damage should be immediately reported to the carrier and a claim registered.

Operating Principe/Delivery Checks/ Installing Blades/Types of Cutting.

OPERATING PRINCIPLE

The following instructions were compiled to provide you information on how to obtain

long and trouble free use of the unit. Periodic maintenance of this unit is essential. Read

the manual in its entirety and follow the instructions carefully. Failure to do so may injure

yourself or a bystander.

DELIVERY CHECKS

Immediately upon taking delivery of your new equipment and before puffing it into

service:

■

Read the handbook completely--it could save a great deal of unnecessary

expense.

■

Read the engine manual supplied.

■

Check the general condition of the equipment-has it been damaged during

delivery?

■

Check engine oil level.

■

Check fuel levels.

Recommend lubricants are detailed in the

CARE AND MAINTENANCE

section.

Summary of Contents for BSC350

Page 1: ...EN RU 01 2014 www helmutworld com support CONCRETE CUTTER BSC350 BSC350H...

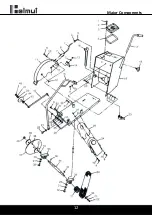

Page 12: ...12 Major Components...

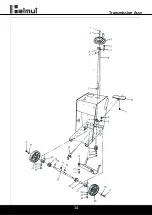

Page 14: ...14 Transmission Assy...

Page 16: ...16 Depth Adjusting Assy...

Page 18: ...18 Engine Assy...

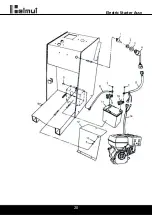

Page 20: ...20 Electric Starter Assy...

Page 22: ...22 4 1 BSC300H BSC300 300 350 80 83 5 5 5 3600 3800 0 9 Honda GX 160 Standart 850 520 1000...

Page 23: ...23...

Page 24: ...24 92 4 10 25 4 22 32...

Page 25: ...25 20 9 5 1200 3 1 2 5 4 6...

Page 26: ...26 2 SAE 15W40 92...

Page 27: ...27 8 10 98 10 0 8 1...

Page 28: ......