EN-12

Figure 17

•

Hold the torch at a 45° angle with the

workpiece. Press the trigger to obtain a pilot

arc. Transfer the arc to the workpiece.

•

Pull the torch back by keeping a 45° angle

with the workpiece and a certain distance

between the torch tip and the molten metal to

avoid consumable life reduction or damage

to the torch.

Changing the torch’s angle change the di-

mensions of the gouge.

•

The gouge profile may vary in accordance with:

1.

speed of the torch over the workpiece

2.

the torch-to-work standoff distance

3.

the angle of the torch to the workpiece

4.

the adjusted current output.

•

To increase width:

- Increase the standoff and/or the current.

- Decrease the speed and/or the angle.

•

To decrease width:

- Increase the speed and/or the angle.

- Decrease the standoff and/or the current

•

To increase depth:

- Decrease the speed and/or standoff.

- Increase the current and/or the angle.

•

To decrease depth:

- Decrease the current and/or the angle.

- Increase the speed and/or standoff.

CUTTING WITH CNC

•

Select the CNC mode with the selection key

(A) in the control panel.

•

Follow indications at paragraph “Connection

of the machine to a CNC”

•

Since the equipment with mechanized torch

can be used with different cutting tables, for the

operations in such configuration it is necessary

to consult the manufacturer’s instructions.

WARNING

Disconnect primary power at the source

and wait that the torch has cooled before

disassembling the torch or torch leads.

Frequently review the Important Safety

Precautions at the front of this Manual. Be

sure the operator is equipped with proper

gloves, clothing, eye and ear protection.

Make sure no part of the operator’s body

comes into contact with the work piece

while the torch is activated.

CAUTION

Sparks from the cutting process can cause

damage to coated, painted, and other sur-

faces such as glass, plastic and metal.

NOTE

Handle torch leads with care and protect

them from damage.

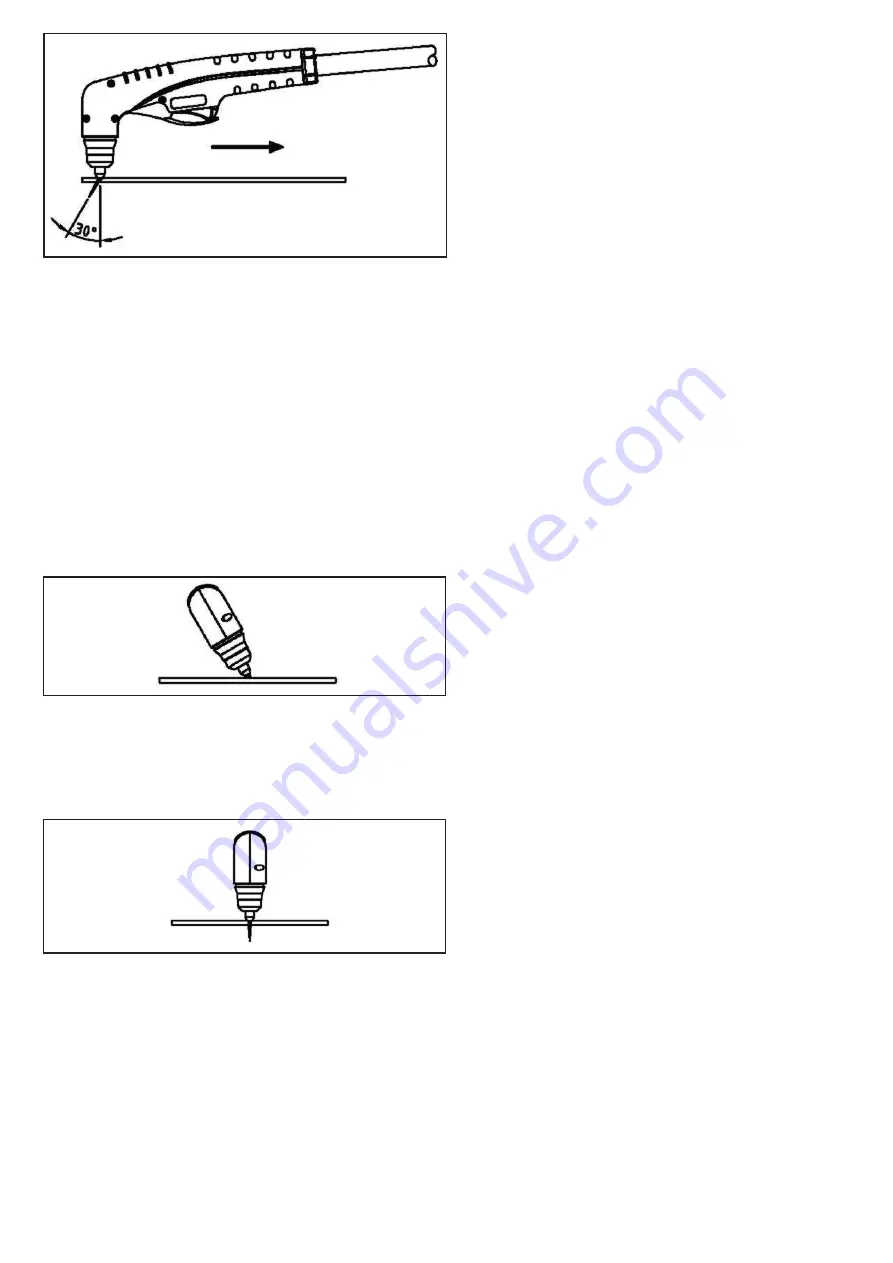

Figure 19

PIERCING WITH A HAND TORCH

Note: Recommended maximum piercing

capacity depends on the torch and on the

cutting current of the cutting unit. Refer to

the torch specification sheet provided with

the cuttig unit. If necessary to make a cut

on a metal sheet with a tickness more than

the maximum piercing capacity without

an edge start, make a hole ø 6mm at least

using an electric drill to start cutting.

•

When piercing with a hand torch, tip the torch

slightly.

Figure 18

•

Complete the pierce off the cutting line and

then continue the cut onto the line. Hold the

torch perpendicular to the workpiece after the

cut is complete. Fig.19

•

Clean spatter and scale from the shield cup

and the tip as soon as possible.

GRATES CUTTING

•

Select the automatic pilot arc mode with the

selection key (A) in the control panel.

GOUGE

•

Select the gouge mode with the selection key

(A) in the control panel.

•

Hold the torch with torch tip within 1.5 mm

from the workpiece.