EN-4

Figure 8

Using the arc welding and cutting equipment requires

strict respect for safety conditions regarding electric

currents. Make sure that no metallic parts accessible

to the operators may come into direct or indirect

contact with a phase conductor or with the neutral

of the power grid.

All electrode holders and torches used must be in

good conditions. Do not coil the cables around your

body and never point the torchs to other people

(Fig. 9).

Figure 9

Make sure that no power cables from other ap-

pliances, control lines or phone cables are near the

generators.

Any other electric equipment in the welding or cutting

area must be in conformity with the corresponding

EMC regulation.

Caution: Access to the the working area

and near the welding/cutting operation

generators is forbidden to anyone wearing

pacemakers or other such electric devices.

At least once every 6 months make sure that all

electric appliances and accessories are well insulated.

Contact your supplier for more information on the

maintenance and repair of such equipment.

Warning: Never touch the welding cable or

the electrode and the piece which is being

welded at the same time.

ELECTRIC SYSTEM

Any intervention on electrical and electronic

equipment must be entrusted to qualified technicians

capable of performing such operations.

Prior to connecting your appliance to the power grid,

make sure that the counter, the overload and short-

circuit protection devices, the sockets, the plugs and

the electric system as a whole are compatible with

the maximum power of the appliance and its voltage

(please check the information on the plate) and in

conformity with the norms and regulations in force.

The ground single-phase or three-phase connection

(yellow/green cable) must be protected by a medium

or high-intensity differential-residual current device

(sensitivity between 1 and 30 mA).

If the cable is connected, the earth cable (when

present) must not be interrupted by the protection

device against electric shock. The switch, if present,

must be at “O”; the power cable, if not supplied,

must be of the harmonized type.

Ground all metal parts near the operator, using

cables that are thicker or as thick as the welding

cables.

The protection class of the appliance is IP22S, which

means it prevents:

- manual contact with internal parts in high tempe-

rature, which are moving or live;

- the introduction of solid bodies with more than 12

mm of diameter;

- protection against rain with maximum inclination

of 15°.

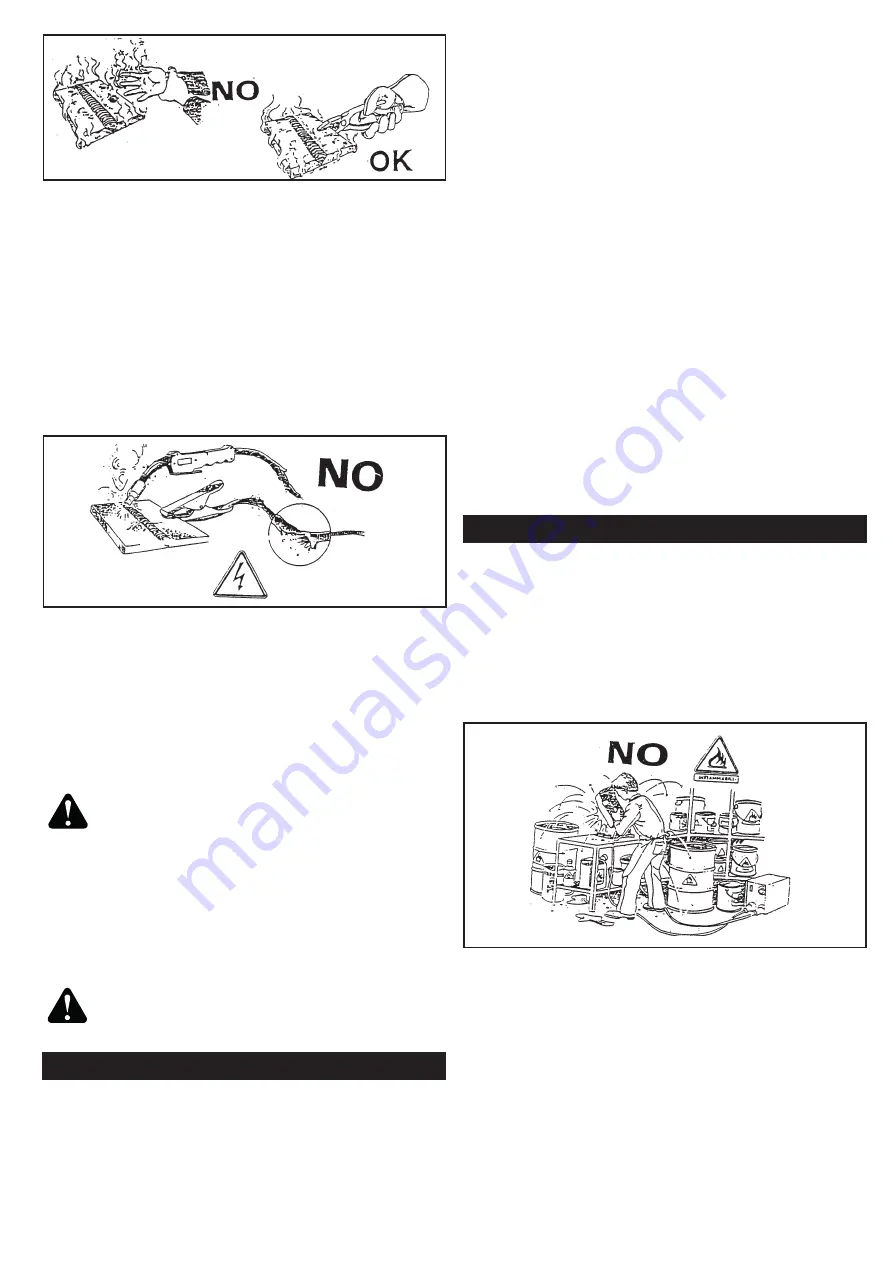

FIRE PREVENTION

The working area must be in conformity with safety

regulations. This means that fire extinguishers must

be installed, compatible with the type of fire which

may happen.

The ceiling, the floor and the doors must be non-

flammable. All combustible material must be moved

away from the workplace (Fig. 10). If this is not

possible, cover it with a fireproof cover.

Figure 10

Before you start welding or cutting, ventilate all areas

that are potentially flammable.

Do not use the equipment in places with significant

concentrations of dust, flammable gas or combusti-

ble liquid vapor.

The generator must be placed on solid, smooth floor,

and should never lean against walls.

Do not weld or cut containers filled with gasoline,

lubricant or other flammable substances.