Preventive Maintenance

20

17730-241

AR2

™

40K • 46K

VISuAL INSpECTION

■

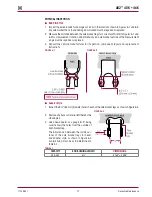

AdApTER STYLE

1 . Chock the wheels .

2 . Visually inspect suspension components for signs of movement or excessive wear .

■

Inspect equalizing beam end connection for signs of excessive wear or looseness

■

Look for worn, frayed or distorted rubber in the beam, see Figure 6-4

■

Look for the equalizing beam to be lower in the axle bracket, see Figure 6-4

■

If it is visually offset a jack test should be performed . Place a jack under each beam end

as shown . Raise the jack to check for movement in the connection or rubber components,

see Figure 6-5

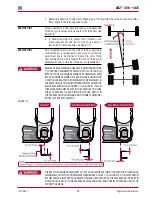

FIguRE 6‑7

3 . The beam end adapter style connections have

an adapter flange with a flat side for assembly

clearance with the axle housing bowl .

■

The flat must be positioned vertically as

shown in Figure 6-7 . If the flat of the adapter

position is incorrect, removal of the fasten-

ers will be necessary to correct position,

refer to the Adapter Style End bushings in the

Component Replacement section

pHYSICAL INSpECTION

■

AdApTER STYLE

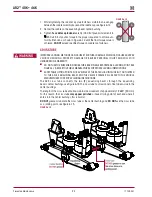

IF BUSHING MOVEMENT OR LOOSENESS IS NOTED IN THE EQUALIZING BEAM END HUB, DO NOT

OPERATE THE VEHICLE . REPLACE THE RUBBER END BUSHINGS AND ALL CONNECTING PARTS .

THE ABOVE CONDITION CAN RESULT IN COSTLY REPAIR, DOWNTIME, POSSIBLE SEPARATION OF

COMPONENTS, ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE, OR PERSONAL INjURY .

SERVICE HINT

An equalizing beam end connection that is visibly cleaner than the other connections may indi-

cate a loose connection .

1 . If bushing movement or looseness is detected in the equalizing beam end hub,

dO NOT

oper-

ate vehicle . Replace the equalizing beam end bushings and all connecting parts . Refer to the

Component Replacement section of this publication .

2 . Check and record torque values, see Figure 6-8 . Ensure all fasteners are tightened to the

following:

■

40K

— 225 ± 15 foot pounds torque

■

46K

— 470 ± 25 foot pounds torque

3 . Recheck equalizing beam end connections for signs of looseness .

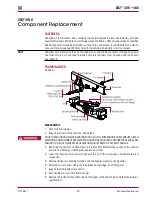

FIguRE 6‑8