Preventive Maintenance

24

17730-241

AR2

™

40K • 46K

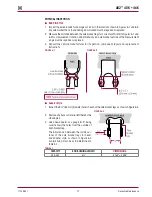

FIguRE 6‑14

1 . While tightening the saddle cap stud fasteners maintain an even gap

between the saddle assembly base and the saddle cap, see Figure 6-14 .

2 . Center the saddle on the equalizing beam center bushing .

3 . Tighten the

saddle cap fasteners

evenly in 50 foot pounds increments to

250 ± 25 foot pounds torque in the proper sequence to achieve uni-

form bolt tension as shown in Figure 6-14 until the final torque value is

achieved .

dO NOT

exceed specified torque on saddle cap fasteners .

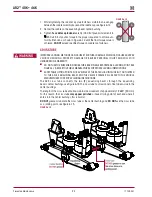

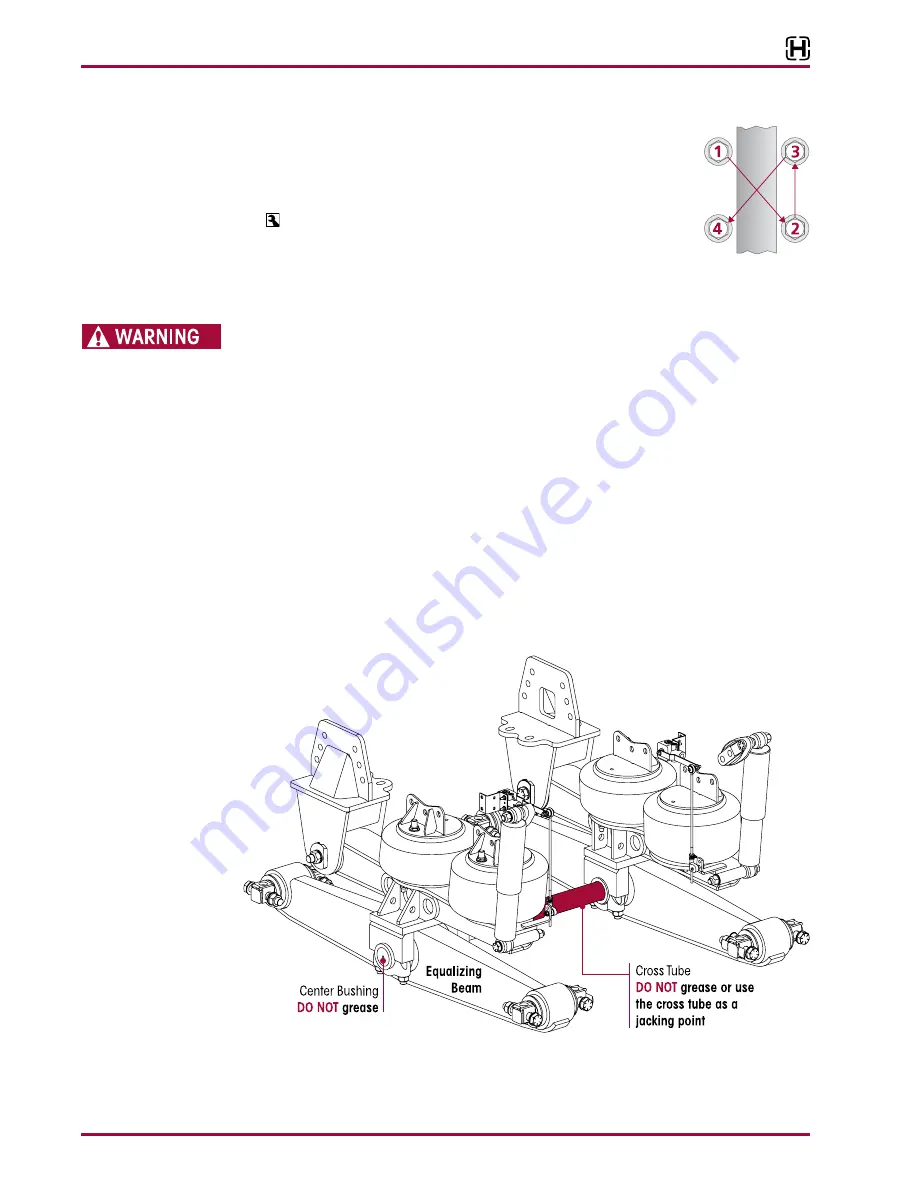

CROSS TuBE

IMPROPER jACKING METHODS CAN CAUSE STRUCTURAL DAMAGE WHICH CAN CAUSE ADVERSE

VEHICLE HANDLING, PROPERTY DAMAGE OR SEVERE PERSONAL INjURY AND WILL VOID

HENDRICKSON’S WARRANTY .

■

DO NOT USE THE SUSPENSION CROSS TUBE, BAR PIN AXLE BRACKETS AS A jACKING POINT, SEE

FIGURE 6-15, REFER TO VEHICLE MANUFACTURER FOR PROPER jACKING INSTRUCTIONS

■

ACCEPTABLE LIFTING POINTS FOR A VEHICLE AT THE RATED LOAD INCLUDE BUT NOT LIMITED

TO: THE AXLE, EQUALIZING BEAM, AND THE VEHICLE FRAME RAIL . REFER TO THE VEHICLE

MANUFACTURER FOR PROPER jACKING INSTRUCTIONS

The AR2 cross tube connects the two (2) equalizing beams through the equalizing

beam’s center bushings, see Figure 6-15 . The cross tube has clearance to float side-to-side in the

center bushings .

The length of the cross tube will allow side-to-side movement of approximately

1 .9685" (50 mm)

.

For this reason, the cross tube

may appear polished

or have missing paint at each end where it

enters into the center bushings, this is normal .

dO NOT

grease or lubricate the cross tube or the center bushing and

dO NOT

use the cross tube

as a jacking point, see Figure 6-15 .

FIguRE 6‑15