Alignment & Adjustments

32

17730-241

AR2

™

40K • 46K

6 . Verify all suspension components are in good condition . Repair or replace any worn or damaged

suspension components before proceeding with the alignment process .

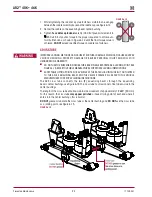

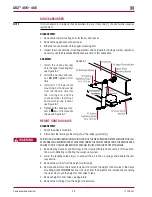

7 . Ensure all drive axle tires are the same size .

8 . Measure from the outside of the frame rail to the rim flange of the inner tire . Record the mea-

surement

A

and

B

, see Figure 7-6 .

9 . Measure the same distance on the opposite side of the same axle . Record the measurement

C

and

D

, see Figure 7-6 .

10 . Verify the lateral alignment is within the vehicle manufacturer’s specifications . Adding or remov-

ing shims that are located between the transverse torque rod and frame rail will normally correct

the lateral alignment .

■

A general rule of thumb is to use a shim with a thickness that is half of the difference

between the two measurements

ExAMpLE

If the lateral alignment is out of specification by ¼" (6 mm), remove or install a

1

⁄

8

" (3 mm) shim

between the transverse torque rod and frame rail as needed .

NOTE

Hendrickson recommends the use of Grade 8 bolts and Grade C locknuts be used for all torque

rod attachments .

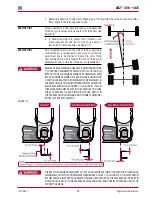

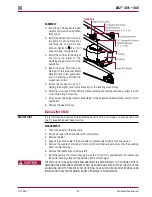

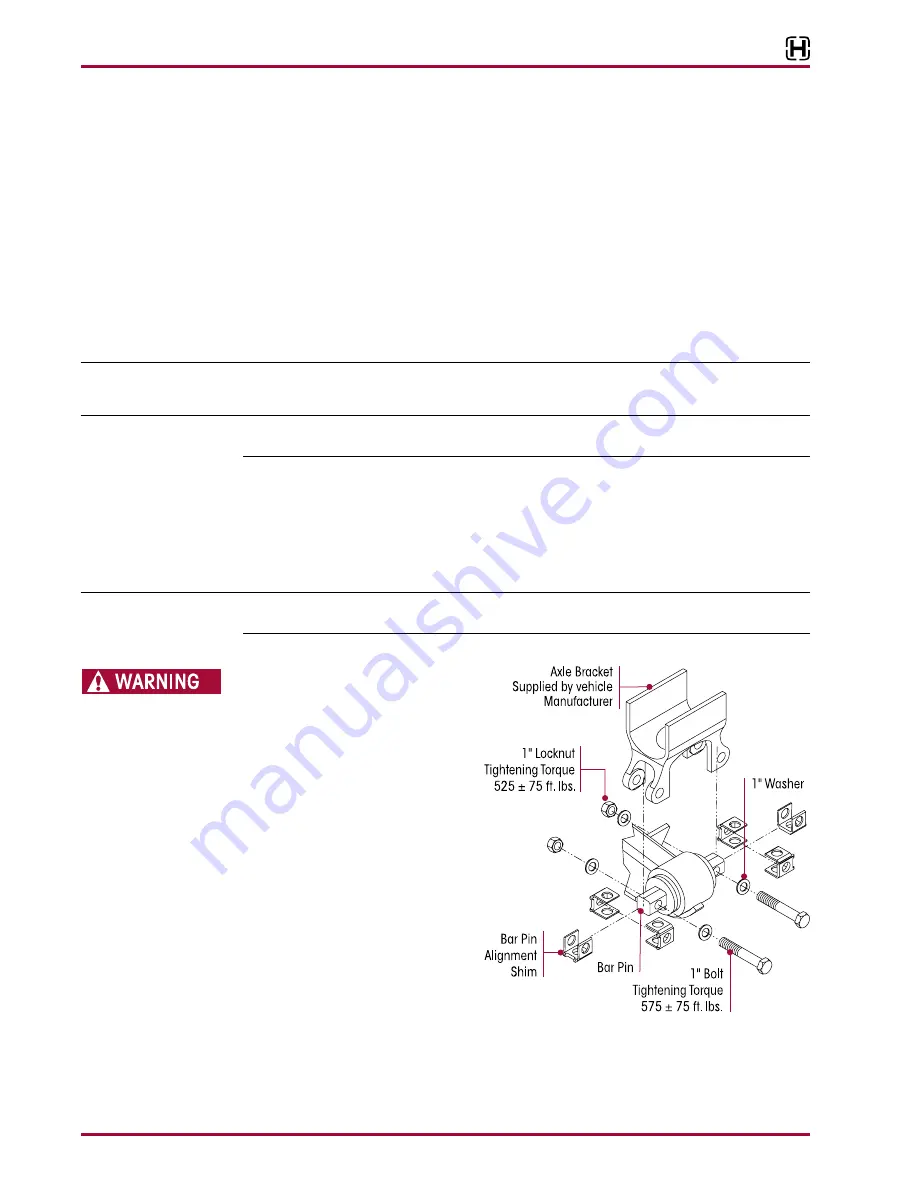

BAR pIN wITH SHIMS ALIgNMENT

The alignment feature consists of specially designed, tight tolerance steel shims which fill the

3

⁄

8

"

(9 .5 mm) total gap between the bushing’s bar pin and the axle bracket legs . The gap must be

filled by placing the shims on the bushing assembly in one of the positions shown in Figure 7-7

or 7-9 . Hendrickson has three (3) shim design options for alignment, see Figure 7-10 .

NOTE

Drive axle alignment with suspensions equipped with adapter style beam or non-shim style end

connections

ARE NOT

adjustable .

FIguRE 7‑7

A BAR PIN SHIM MUST BE INSTALLED

AT EACH BOLT LOCATION . THE SAME

PART NUMBER SHIM IN THE SAME

ORIENTATION MUST BE USED AT BOTH

BOLT LOCATIONS ON ANY ONE (1)

END BUSHING . DO NOT INSTALL OR

STACK MORE THAN ONE (1) SHIM AT

EACH BOLT LOCATION . USE GENUINE

HENDRICKSON BAR PIN SHIMS, DO NOT

USE STANDARD WASHERS . FAILURE TO

FOLLOW THESE WARNINGS MAY RESULT

IN IMPROPER VEHICLE ALIGNMENT,

FRACTURE OF THE AXLE BRACKET OR

BAR PIN WHICH COULD RESULT IN

THE ADVERSE VEHICLE HANDLING

AND POSSIBLE PERSONAL INjURY OR

PROPERTY DAMAGE .

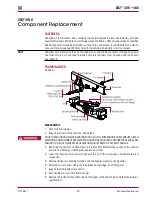

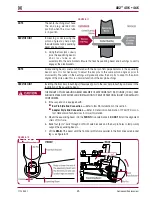

ALIgNMENT AdjuSTMENT

pROCEduRE

Computerized alignment equipment is the preferred method of measuring alignment . To calculate

the shim thickness required, the target offset must be converted to thrust angle, see alignment

equipment manufacturer for procedures . If alignment of the drive axles is required, as determined

by an alignment inspection procedure, the following Steps will need to be performed .