17730-241

41

Component Replacement

AR2

™

40K • 46K

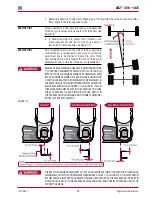

INSpECTION

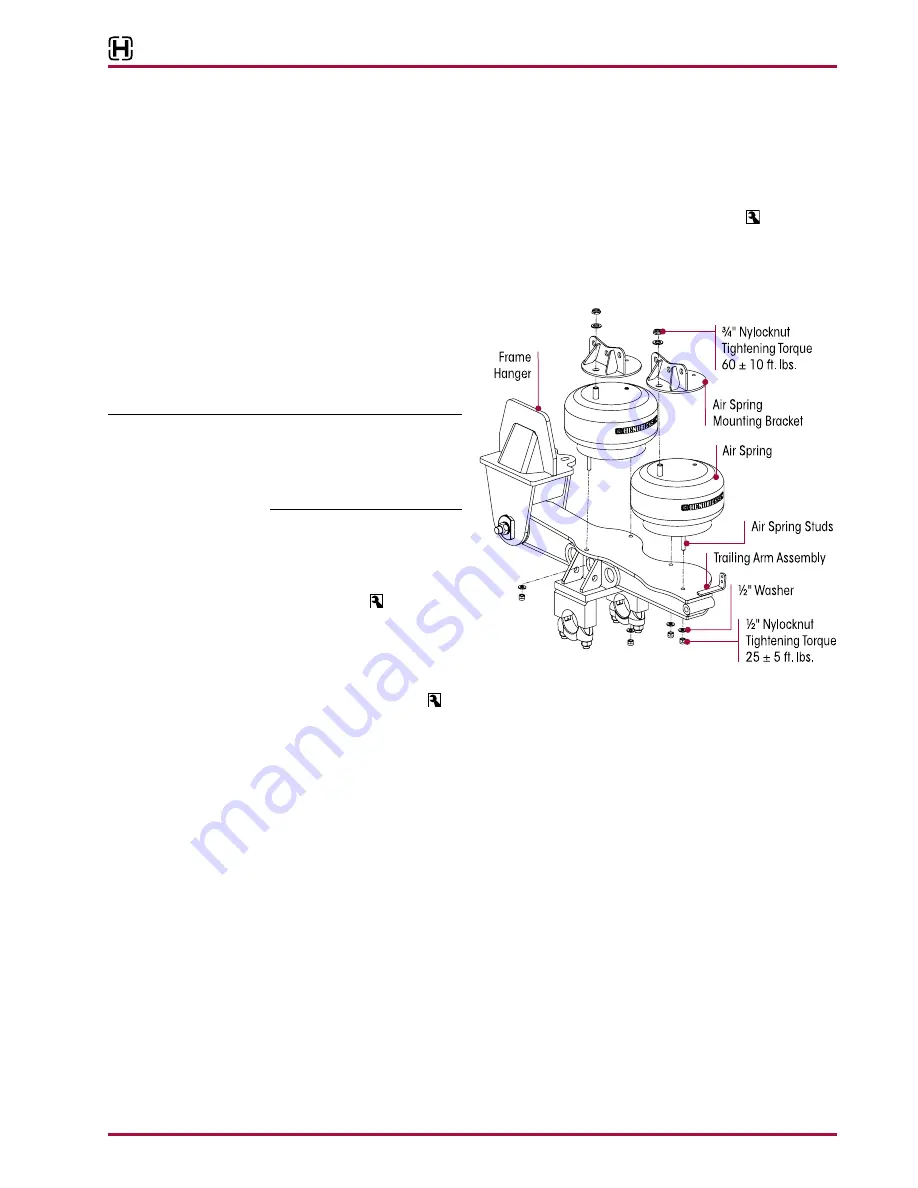

1 . Inspect the mounting surfaces on the trailing arm and the upper air spring mounting bracket

for cracks or damage . Replace as necessary .

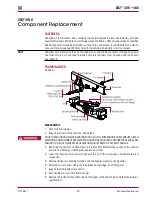

ASSEMBLY

1 . Install the ½" studs in the bottom of the new air spring and tighten to

25 ± 5 foot

pounds torque .

2 . Assemble the air spring to air spring frame hanger by inserting studs into appropriate holes .

The ¾" combo stud faces outboard of the vehicle .

FIguRE 8‑6

3 . Install the air spring into the

trailing arm assembly by

inserting the studs into the

trailing arm mounting holes,

see Figure 8-6 .

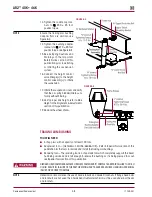

SERVICE HINT

Depending on the frame height

of the vehicle it may be neces-

sary to compress the air spring

to facilitate installation into the

frame bracket and trailing arm .

4 . Assemble the washers and

locknuts which connect the

air spring to the trailing arm

assembly and tighten the

locknuts to

25 ± 5 foot

pounds torque as shown in

Figure 8-6 .

5 . Assemble the washers and

locknuts on the combo stud which connect air spring to the frame hanger bracket . Tighten the

combo stud locknut to

60 ± 10 foot pounds torque as shown in Figure 8-6 .

6 . Install the air fitting to the air spring using Teflon thread seal .

7 . Install the air lines to the air springs .

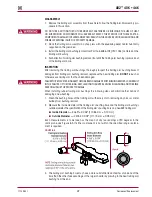

8 . Lower the frame of vehicle .

9 . See Air Spring Cautions and Warnings in the Important Safety Notice section of this publica-

tion prior to deflating or inflating the suspension system .

10 . Inflate the suspension by connecting the height control valve linkage(s) to the leveling

valve arm(s) .

11 . Verify the air springs inflate uniformly without binding and that the vehicle air system is at the

correct operating air pressure .

12 . Remove the frame supports .

13 . Verify proper ride height, refer to Ride Height in the Alignment & Adjustments section of this

publication .

14 . Remove the wheel chocks .