17730-241

45

Component Replacement

AR2

™

40K • 46K

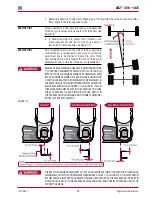

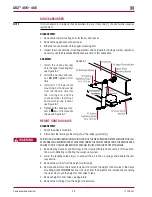

FIguRE 8‑11

NOTE

The center bushing must have

the end plug welded into

position when the cross tube

is in position .

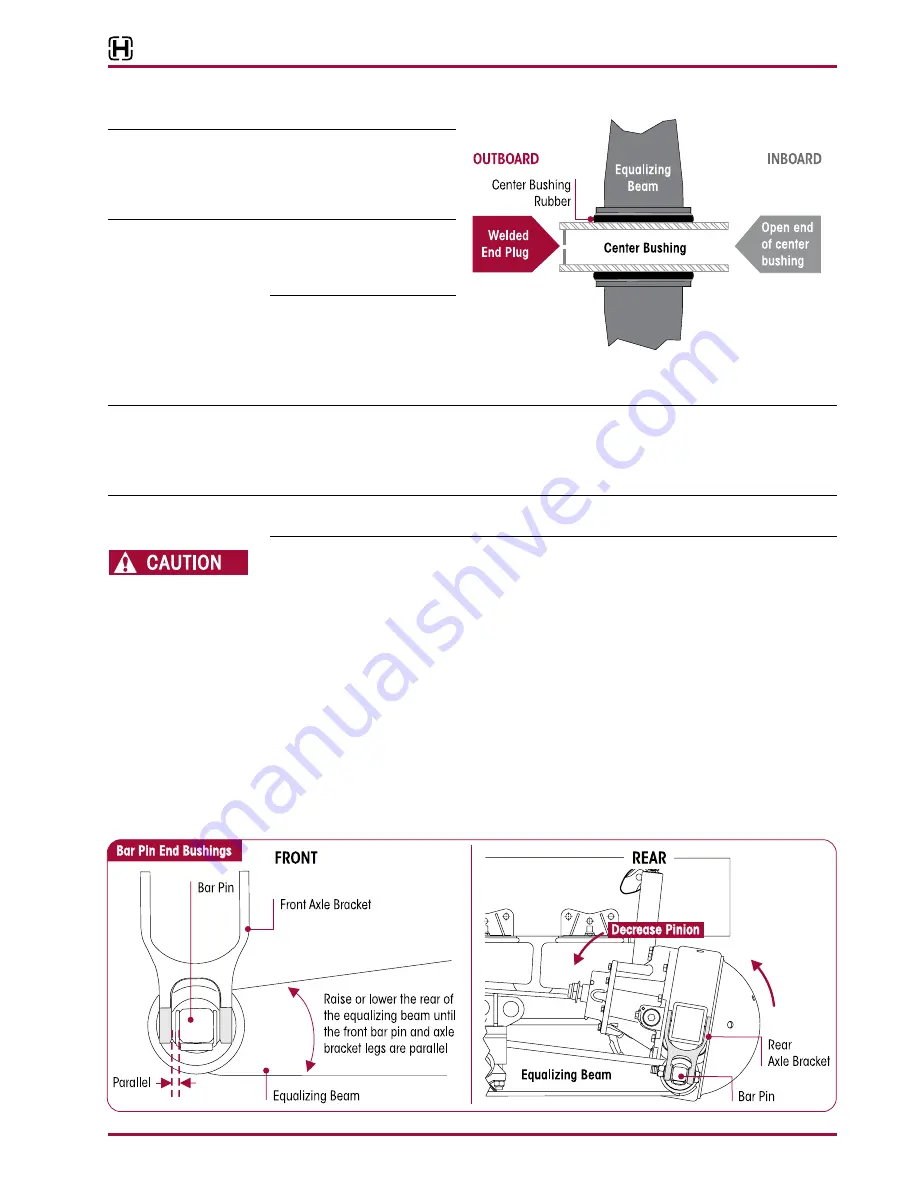

SERVICE HINT

Increasing or decreasing the

pinion angle may help align

the axle bracket and equalizing

beam end bushings .

3 . Using the floor jacks, slowly

raise the equalizing beams

a n d c ro s s t u b e a s a n

assembly into the axle brackets . Ensure that each equalizing beam end bushings correctly

engages the axle brackets .

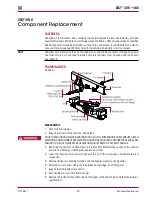

NOTE

All equalizing beams are manufactured with the bar pin flats perpendicular to the equalizing

beam’s axis . It is not necessary to adjust the bar pins to the same pinion angle as prior to

disassembly . The rubber in the bushings will gradually allow the bar pins to adapt to the pinion

angles of the drive axles . This is a normal function of the bar pin bushings .

SERVICE HINT

Installing the front bar pin bushings (if equipped) prior to the rear bar pin bushings will ease in the

installation of the equalizing beam .

THE WEIGHT OF THE EQUALIZING BEAM ASSEMBLY IS APPROXIMATELY 155 POUNDS (70 KG) . CARE

SHOULD BE TAKEN AT REMOVAL AND INSTALLATION TO PREVENT PERSONAL INjURY OR DAMAGE TO

COMPONENTS .

4 . If the suspension is equipped with:

■

Bar pin Style End Connection —

Refer to Bar Pin Installation in this section

■

Adapter Style End Connection —

Refer to Hendrickson Publication 17730-190 or con-

tact Hendrickson Tech Services for more information

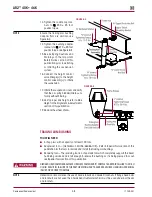

5 . Mount the equalizing beam into the

FRONT

drive axle brackets .

dO NOT

install the alignment

shims at this time .

6 . Slide four (4) ¾" bolts through both front axle brackets and the bar pin holes to temporarily

support the equalizing beams .

7 . Lift the

REAR

of the beam until the front bar pin flats are parallel to the front drive axle bracket

legs, see Figure 8-12 .

FIguRE 8‑12