Component Replacement

48

17730-241

AR2

™

40K • 46K

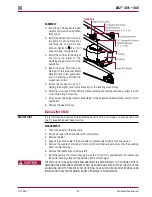

FIguRE 8‑15

28 . Apply Loctite 262

ONLY

on the

upper half area of the saddle

cap stud that inserts into the trail-

ing arm .

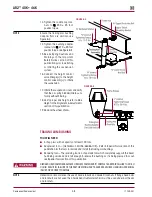

29 . Tighten the

saddle cap

fasteners

evenly in 50 foot pounds incre-

ments in the proper sequence for

uniform bolt tension as shown in

Figure 8-16 until the final torque

value of 250 ± 25 foot pounds

torque is achieved .

dO NOT

exceed specified torque on saddle

cap fasteners . Maintain an even

gap between the trailing arm assembly and saddle cap, see Figure 8-14 .

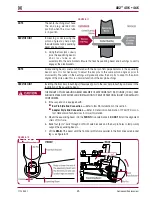

FIguRE 8‑16

NOTE

Tightening the saddle cap stud fasteners properly will help prevent wear

of mating components, beam center bushing, trailing arm assembly, and

saddle cap .

30 . Install the tires .

31 . Remove the supports from the drive axles and lower the vehicle onto the

ground .

32 . Remove the wheel chocks .

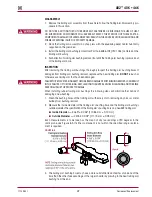

CENTER BuSHINg

YOu wILL NEEd

■

A shop press with a capacity of at least 100 tons

■

Center bushing tool — (Hendrickson Part No . 66086-100) – Refer to Special Tools section of

this publication for the tools to remove and install the rubber center bushings

■

Receiving tool — The receiving tool is a shop made tool which completely supports the beam

hub being serviced and is tall enough to receive the bushing as it is being pressed in or out,

refer to the Special Tools section of this publication

DISCARD USED FASTENERS . ALWAYS USE NEW FASTENERS TO COMPLETE A REPAIR . FAILURE TO DO SO

COULD RESULT IN FAILURE OF THE PART OR MATING PARTS, ADVERSE VEHICLE HANDLING, PERSONAL

INjURY, OR PROPERTY DAMAGE .

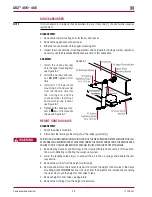

dISASSEMBLY

NOTE

Whenever an equalizing beam is removed for repair, or inspection of the equalizing beam end

connection reveals movement, measure the distance between the axle bracket legs for correct

width . Refer to Axle Bracket in Preventive Maintenance section of this publication for measure-

ment location and proper dimensions . An axle bracket outside of the proper dimensions must

be repaired or replaced . Consult the vehicle manufacturer for inspection, component repair and

replacement instructions .

1 . Remove the equalizing beam assembly from the vehicle . Follow the equalizing beam disas-

sembly procedure in this section .

DO NOT USE A CUTTING TORCH TO REMOVE ANY FASTENERS OR BUSHINGS . THE USE OF HEAT

ON SUSPENSION COMPONENTS WILL ADVERSELY AFFECT THE STRENGTH OF THESE PARTS . A

COMPONENT DAMAGED IN THIS MANNER CAN RESULT IN THE ADVERSE VEHICLE HANDLING AND

POSSIBLE PERSONAL INjURY OR PROPERTY DAMAGE .