Component Replacement

50

17730-241

AR2

™

40K • 46K

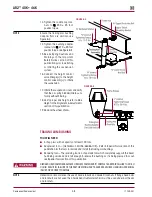

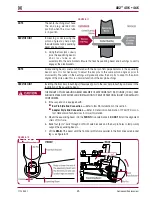

FIguRE 8‑18

7 . Install the center bushing

installation tool and press

in the new center bush-

ing until the outer metal

sleeve is centered in the

equalizing beam’s bore,

see Figure 8-18 .

8 . Install the equalizing beam

onto the vehicle, refer to the

Equalizing Beam Assembly

procedure in this section .

BAR pIN ENd BuSHINgS

WHEN REMOVING AND INSTALLING BUSHINGS IN THE EQUALIZING BEAMS, FOLLOW THE PROCEDURES

OUTLINED IN THIS PUBLICATION . DO NOT USE A CUTTING TORCH TO REMOVE THE BUSHING OUTER

METALS PRESSED IN THE EQUALIZING BEAM BORES . WELDING, TORCHING OR ATTACHING MATERIAL

TO THE EQUALIZING BEAM MUST NEVER BE PERFORMED . THE USE OF HEAT CAN ADVERSELY AFFECT

THE STRENGTH OF THE EQUALIZING BEAMS AND CAN CAUSE DAMAGE TO THE EQUALIZING BEAM

ASSEMBLY, ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL INjURY OR PROPERTY DAMAGE .

NOTE

Hendrickson bar pin service kits containing alignment shims, (Kit No . 34013-088L) or (Rotating

Bar Pin Bushing Kit No . 34013-188) contain all the components required for one (1) equalizing

beam end, see Parts List section of this publication .

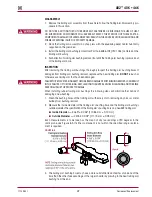

YOu wILL NEEd

■

A shop press with a capacity of at least 100 tons

■

Bar pin style tool — Refer to Special Tools section of this publication

■

Installation tool Part No . 66086-103

■

Removal tools Part No . 66086-104 and 66086-105

■

Shop Made Receiving tool — Refer to the Special Tools section of this publication

NOTE

The receiving tool completely supports the equalizing beam hub being serviced and is tall enough

to receive the bushing as it is being pressed in or out .

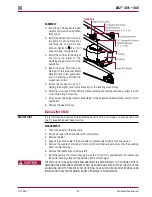

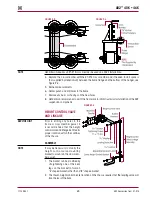

REMOVAL

NOTE

Whenever an equalizing beam is removed for repair, or inspection of the equalizing beam end

connection reveals movement, measure the distance between the axle bracket legs for correct

width . Refer to Axle Bracket in Preventive Maintenance section of this publication for measure-

ment location and proper dimensions . An axle bracket outside of the proper dimensions must

be repaired or replaced . Consult the vehicle manufacturer for inspection, component repair and

replacement instructions .

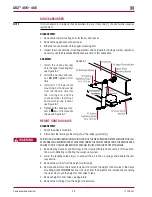

1 . Remove equalizing beam assembly from vehicle as detailed in the Equalizing Beam

Disassembly instructions in this section .

2 . Place the equalizing beam in the shop press with the beam end hub squarely supported on

the press bed .

NOTE

If replacing the bar pin with a rotating bar pin end bushing, it is not necessary to mark the orienta-

tion of the bar pin flats .

3 . Prior to removal, mark the orientation of the bar pin flats, see Figure 8-19 . Mark orientation the

equalizing beam with a paint stick .