17730-241

51

Component Replacement

AR2

™

40K • 46K

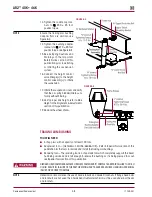

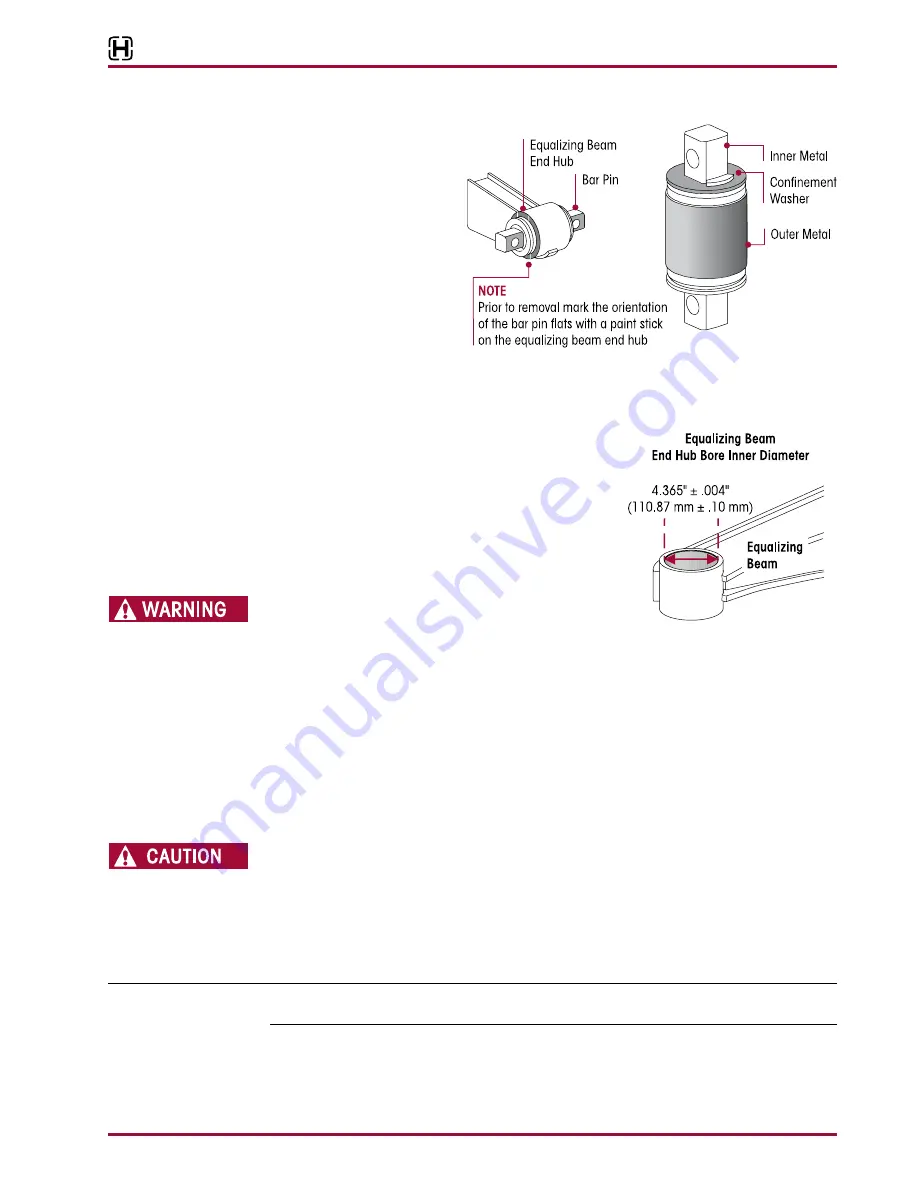

FIguRE 8‑19

FIguRE 8‑20

4 . Press on the end bushing

inner metal, see Figure

8-20, of the end bush-

ing until the inner metal

is flush with the top of

the beam end hub . This

will dislodge the confine-

ment washer and move

the bushing rubber away

from the outer metal of the

bushing so the removal

tool can be installed .

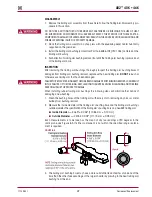

5 . Center the bushing push out tool directly on the bushing’s outer metal and press the bushing

out of the equalizing beam end hub .

6 . After removing the bar pin end bushings, thoroughly inspect each end hub bore .

FIguRE 8‑21

INSpECTION

After removing the bar pin end bushings, thoroughly

inspect the beam bores . If the equalizing beam is dam-

aged from end bushing removal, replacement of the

equalizing beam is required, replace with a new equaliz-

ing beam .

dO NOT

re-bush or otherwise use an equalizing

beam that has been damaged .

FAILURE TO REPLACE AN EQUALIZING BEAM THAT HAS BEEN

DAMAGED FROM BUSHING REMOVAL CAN RESULT IN THE

FAILURE OF THAT BEAM, LEADING TO ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL INjURY

OR PROPERTY DAMAGE .

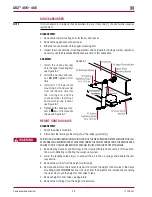

When installing bar pin end bushings the following steps will minimize the chance of damaging

a new bushing:

1 . Clean the end hub bores with emery cloth or hone, removing any nicks or metal buildup from

bushing removal .

2 . Measure the equalizing beam end hub bore inner diameter and the bushing outer diameter .

The Hendrickson specification for the equalizing beam end hub bore diameter of the equal-

izing beam is 4 .365" ± .004", (110 .87 mm ± .10 mm) see Figure 8-21 . If components are

NOT

within the specified range, replacement is required .

ALWAYS USE THE BUSHING’S OUTER METAL FOR PRESSING OPERATIONS, UNLESS OTHERWISE

INSTRUCTED . PRESSING ON THE BUSHINGS INNER METAL MAY DAMAGE THE BUSHING REQUIRING

BUSHING REPLACEMENT .

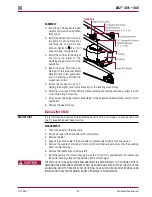

INSTALLATION

1 . Place the equalizing beam in a shop press with the end hub, see Figure 8-22, squarely sup-

ported on the press bed or receiving tool, see Special Tools section of this publication .

SERVICE HINT

The end hub bore may have a more substantial leading chamfer at one end of the bore than the

other . Take advantage of the larger chamfer by pressing in the new bushing from this end .