Component Replacement

60

17730-241

AR2

™

40K • 46K

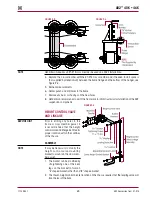

FIguRE 8‑41

xTRB TORquE ROd BuSHINgS

YOu wILL NEEd

■

A vertical press with a capacity of at least 10 tons

■

Shop made receiving tool and installation / removal

tool, see the Special Tools section of this publication

for more information

DO NOT USE HEAT OR USE A CUTTING TORCH TO REMOVE

THE BUSHINGS FROM THE TORQUE ROD . THE USE OF HEAT

WILL ADVERSELY AFFECT THE STRENGTH OF THE TORQUE

ROD, HEAT CAN CHANGE THE MATERIAL PROPERTIES . A COMPONENT DAMAGED IN THIS MANNER CAN

RESULT IN ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL INjURY OR PROPERTY DAMAGE .

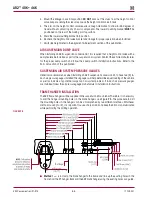

dISASSEMBLY

FIguRE 8‑42

1 . Remove the torque rod(s) as detailed in Torque Rod

Disassembly instructions in this section .

SERVICE HINT

When servicing a straddle mount bar pin bushing assem-

bly, mark the clocking position of the straddle mount bar

pin flats with a paint stick on the torque rod end hub prior

to disassembly, see Figure 8-42 . This marking will serve as

a guide when installing the new bushing assembly so the

original clocking position can be retained .

2 . Mark the clocking position of the straddle mount bar

pin flats with a paint stick on the torque rod end hub

prior to disassembly, see Figure 8-42 .

3 . Support the torque rod end hub centered on the receiv-

ing tool . Be sure the torque rod is squarely supported on

the press bed for safe ty .

4 . Push directly on the straddle mount bar pin, until the top of the bar pin is level with the top of

torque rod end hub, see Figure 8-43 .

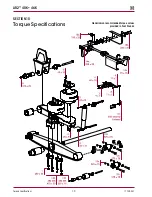

FIguRE 8‑43

FIguRE 8‑44

5 . P l a c e t h e s h o p m a d e

removal tool on the bar pin

and press until the bushing

clears the torque rod hub,

see Figure 8-44 .

6 . Remove the fastener from

the tapered bar pin bush-

ing, and support the torque

rod hub on the receiving

tool with the tapered stud

pointing down and the end

hub centered on the tool .

Be sure the torque rod is

squarely supported on the

press bed for safety .

Mark the clocking position of the

bar pin flats with a paint stick

on the torque rod end hub