Preventive Maintenance

16

17730-241

AR2

™

40K • 46K

■

Equalizing beam assembly, end connection and saddle cap fasteners

— Check the overall

condition of the equalizing beam for dents, dings, or other damage . Inspect the equalizing

beam end connection and saddle cap fasteners for proper torque . The beam end connec-

tion must sustain proper clamp force of the axle bracket legs to the bushing inner casting

prevent any movement of the beam end connection . See Equalizing Beam End Connection

in this section . See Torque Specifications section of this publication for recommended

torque requirements .

■

Fasteners

— Look for any loose or damaged fasteners on the entire suspension . Make sure

all fasteners are tightened to a torque value within the specified torque range . See Torque

Specifications section of this publication for recommended torque requirements . Use a cali-

brated torque wrench to check torque in a tightening direction . As soon as the fastener starts

to move, record the torque . Correct the torque if necessary . Replace any worn or damaged

fasteners with genuine specified fasteners . For fasteners not supplied by Hendrickson, see

vehicle manufacturer .

■

Torque rods

— All torque rods must be inspected every six months for looseness, torn or

shredded rubber, bushing walk-out, and for proper fastener torque . If there is metal-to-metal

contact in the bushing joint, this is a sign of excessive bushing wear and the bushing needs

to be replaced .

■

wear and damage

— Inspect all parts of the suspension for wear and damage . Look for bent

or cracked parts . Replace all worn or damaged parts .

■

Frame hanger bracket

— Check for any signs of loosening or damage at the pivot connec-

tions . Check for cracks, damage, or any signs of looseness at the mounting fasteners . Replace

all worn or damaged parts .

■

Height control valve and air lines

— Check the suspension air system for air leaks . Check

all air lines for proper routing . Check for chafing or pinched air lines . Check the height control

valve linkage for damage or interference with peripheral components . Replace all worn or

damaged parts .

■

Trailing arm assembly

— Check the overall condition of the trailing arm for cracks, dents,

dings, or other damage on the trailing arm assembly . Check the trailing arm bushings for tear-

ing or extreme bulging . Check for any metal to metal contact in the bushed joints . Replace all

worn or damaged parts .

■

Tire wear

— Inspect the tires for wear patterns that may indicate suspension damage or

misalignment . Replace all worn or damaged parts .

See vehicle manufacturer’s applicable publications for other preventive maintenance

requirements .

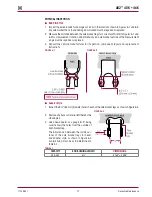

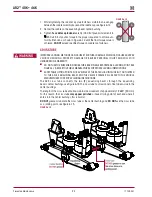

BEAM ENd AxLE BRACKETS

NOTE

The axle brackets are furnished and welded into position by the vehicle manufacturer or axle

manufacturer .

When an equalizing beam is removed for repair or inspected, check for signs of movement . Also

inspect the axle brackets:

■

For damage and / or cracks, see Figures 6-1 and 6-2

■

Measure the two dimensions on the axle bracket legs, see Figure 6-2

An axle bracket outside of the measurement range, damaged or cracked must be repaired

or replaced . Consult the vehicle manufacturer for inspection, component repair and replace-

ment instructions .