17730-241

29

Alignment & Adjustments

AR2

™

40K • 46K

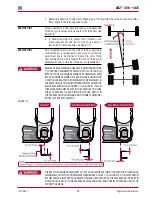

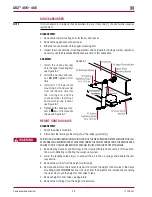

4 . When checking or adjusting ride height, verify and maintain the vehicle’s air system at full

operating pressure .

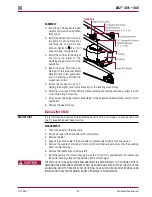

SERVICE HINT

It is important that the height control valves be cycled completely before and after any ride height

adjustments . The cycling of the height control valves will help to make the adjustment more accurate .

PRIOR TO AND DURING DEFLATION AND INFLATION OF THE AIR SUSPENSION SYSTEM, ENSURE THAT ALL

PERSONNEL AND EQUIPMENT ARE CLEAR FROM UNDER THE VEHICLE AND AROUND THE SERVICE AREA,

FAILURE TO DO SO CAN CAUSE SERIOUS PERSONAL INjURY, DEATH, OR PROPERTY DAMAGE .

SOME VEHICLE APPLICATIONS, SUCH AS VEHICLES EQUIPPED WITH OUTRIGGERS, RETAIN SOME AIR

PRESSURE IN THE AIR SPRINGS AT ALL TIMES . PRIOR TO PERFORMING ANY MAINTENANCE, SERVICE,

OR REPAIR OF THE SUSPENSION, VERIFY EACH AIR SPRING IS COMPLETELY DEFLATED . FAILURE TO DO

SO COULD RESULT SERIOUS PROPERTY DAMAGE AND / OR SEVERE PERSONAL INjURY .

5 . See additional Air Spring Cautions and Warnings in the Important Safety Notice section of this

publication prior to deflating or inflating the air system .

6 . Detach the upper rubber grommets of the height control valve linkages from the height control

valve arms and exhaust the suspension system air by lowering the height control valve arms .

7 . Refill the suspension by raising the height control valve arms by hand, so that the air springs

are above the proper ride height .

8 . Lower the height control valve arms to exhaust the suspension air system until the suspension

is at proper ride height .

NOTE

Adjustments to one (1) height control valve may affect ride height setting on the other height control

valve . Verify ride height is correct at both height control valves whenever an adjustment is made .

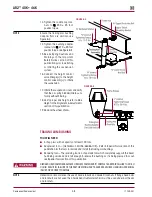

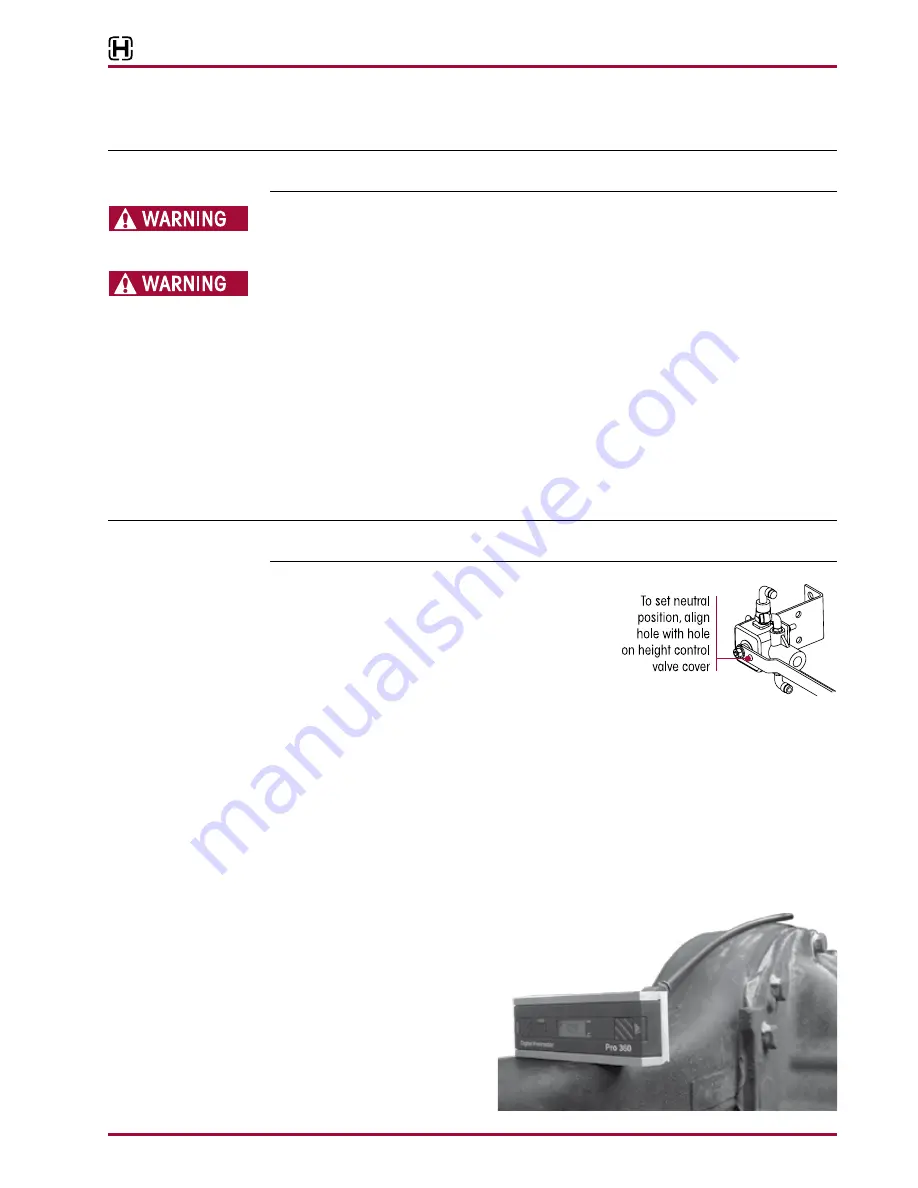

FIguRE 7‑3

9 . Use a

1

⁄

8

" wooden dowel rod (golf tee) to set the neu-

tral position for each height control valve by aligning

the hole in the leveling arm with the hole in the height

control valve cover, as shown in Figure 7-3 .

dO NOT

use a metal rod or nail as this may cause damage to

the height control valve .

10 . Steps 7 to 9 might need to be repeated using one (1) height control valve at a time .

11 . Correct the adjustable valve arm joints so the rubber grommets can be reconnected to the

height control valve arms at the proper height . Check the rubber components for any tearing

or damage, replace as necessary .

12 . Connect the rubber grommets to the height control valve arms .

13 . Tighten the clamps on the adjustable valve arm joints with a screwdriver until securely fas-

tened, see Figure 7-1 . Remove the dowel from the height control valves .

14 . Verify the ride height is correct by performing the Ride Height Inspection as detailed in

this section .

FIguRE 7‑4

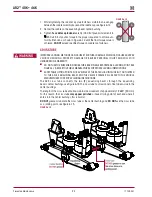

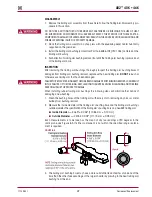

AxLE pINION ANgLE

Drive axle pinion angles are estab-

lished by the vehicle manufacturer .

If pinion angle adjustment is

required, check for proper angles

with the vehicle manufacturer .

Pinion angle is set by the longitudi-

nal torque rod length .