10

T72007 A

HXL5

®

Hub Maintenance Procedures

B�

if the seal is on the spindle

- Using a brass,

leather or other soft-faced mallet, drive the seal

off the spindle by carefully striking the seal

from the back side�

noTiCe: any damage to the spindle’s

machined surfaces can effect wheel

end performance.

9�

remove, clean and inspect

inner bearing� Replace

if needed�

SpinDle preparaTion

Before installing or re-installing the hub, follow this

procedure to ensure hub and spindle machined

surfaces are clean and undamaged�

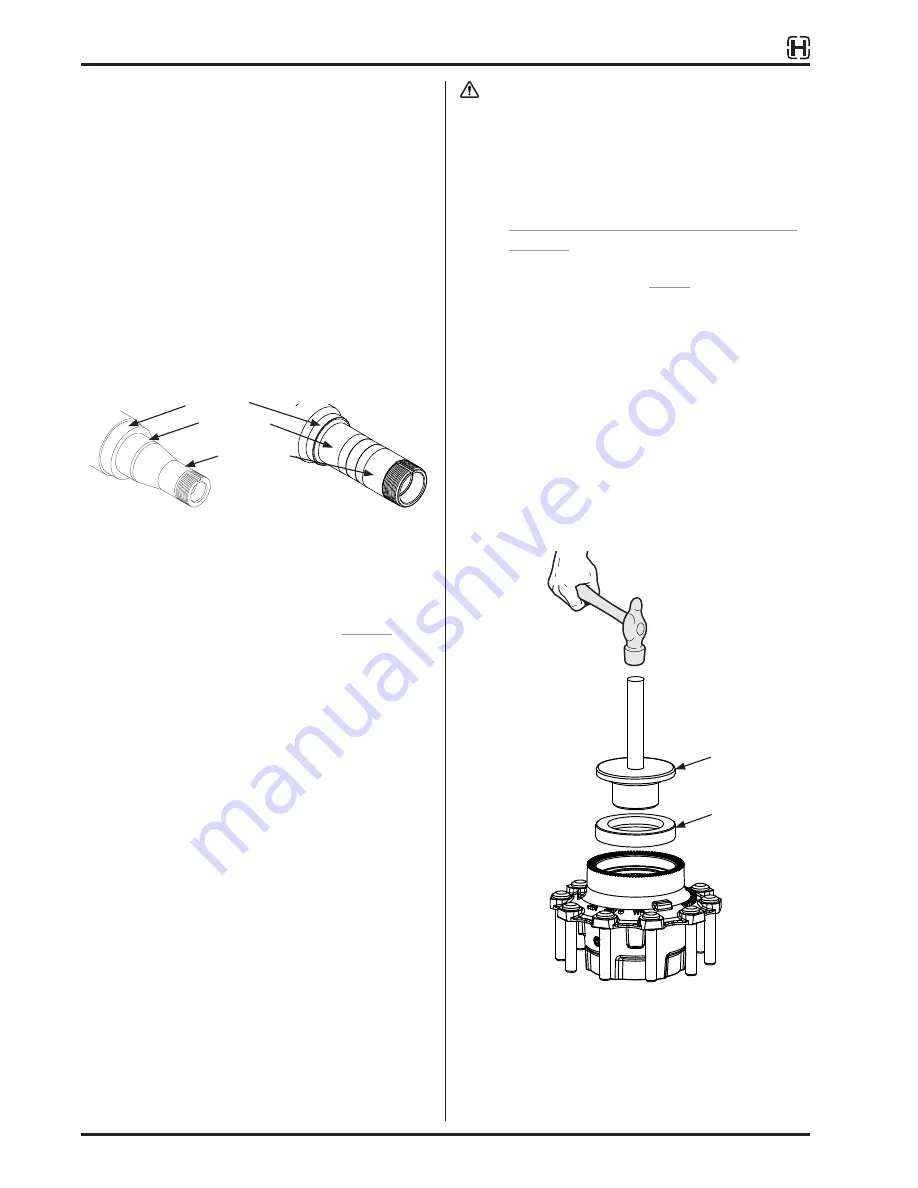

HN spindle

HP spindle

Figure 8: Spindle seal & bearing

journal

s

1�

remove old lubricant

and thoroughly clean

spindle�

2�

inspect machined spindle

nicks, scratches, burrs or marks� If needed, use

crocus cloth or emery cloth to repair any damaged

areas�

3�

clean spindle threads and keyway thoroughly

with

a wire brush to avoid false bearing adjustments

and to avoid introduction of contaminants into the

lubricant cavity�

4�

thoroughly clean spindle machined surfaces

of

rust, dirt, grease or any other contaminants that

could damage the hub seal and cause it to leak�

5�

Lubricate spindle

bearing surfaces with clean

Chevron Delo

®

Synthetic Grease SF�

noTiCe: To minimize fretting and damage to

wheel-end, lubricate all components

and applicable surfaces using the

same lubricant.

preparinG HuB For re-inSTallaTion

The hub and bearings should be cleaned and inspected

prior to installation�

CauTion: For safety reasons, to prevent injury

and damage to the hub and spindle,

lifting equipment may be required to

lift and support the hub as it is being

installed onto the spindle.

noTe:

If ADB, refer to Hendrickson literature number

Hub and Rotor Assembly and Caliper

for servicing the rotor�

If installing new hub, start with Step 3�

1�

thoroughly clean

the hub bore of any dirt, grease,

rust or any other substance that may be present�

2�

remove

all sharp edges, nicks and burrs from seal

bore, hubcap bore and hubcap mounting surface of

the hub�

3�

inspect

hub seal bore for roughness� If needed, use

emery cloth to remove any burrs or old bore sealant

and wipe hub clean�

4�

ensure

hubcap mounting surface is smooth and

free of debris�

Figure 9: Hub-mounted seal installation

noTe:

HXL5

®

wheel-ends require

chevron delo

®

synthetic Grease sF

�

5�

apply lubricant

to inner bearing�

Seal journal

Inner bearing

journal

Outer bearing

journal

Drive tool

Seal