Preventive Maintenance

14

17730-299

ULTIMAAX

®

for Fire and Rescue Vehicles

■

Equalizing beam assembly

— Check the overall condition of the equalizing beam for dents,

dings, or other damage . Check the beam end connections for tearing or extreme bulging .

Check for any metal-to-metal contact in the bushed joints . Refer to Equalizing Beam End

Connection Inspection in this section .

■

Fasteners

— Look for any loose, missing or damaged fasteners on the entire suspension .

Ensure all fasteners are tightened to a torque value within the specified torque range . See rec-

ommended torque specifications for Hendrickson supplied fasteners in Torque Specification

Section of this publication . For fasteners not supplied by Hendrickson, see vehicle manufac-

turer . Use a calibrated torque wrench to check torque in the tightening direction . As soon as

the fastener starts to move, record the torque . Correct the torque as necessary .

NOTE

Hendrickson recommends the use of Grade 8 bolts, hardened washers, and Grade C locknuts .

Hardened washers are not necessary when flange head fasteners are used .

NOTE

Torque values shown in this publication apply only if Hendrickson supplied fasteners are used . If

non-Hendrickson fasteners are used, follow the torque specification listed in the vehicle manufac-

turer’s service manual .

■

Saddle cap fasteners —

Inspect the locknuts for proper torque to prevent wear of the beam

center bushing into the saddle . See Torque Specification Section of this publication for recom-

mended torque requirements .

■

Shock absorbers —

Look for any signs of dents or leakage . Misting is not considered a leak .

See Shock Absorber Inspection in this section .

■

Transverse torque rods / Longitudinal torque rods

— The torque rods must be connected

and in good working condition when operating the vehicle .

■

Wear and damage

— Inspect all parts of the suspension for wear and damage . Look for bent

or cracked parts .

See vehicle manufacturer’s applicable publications for other preventive maintenance

requirements .

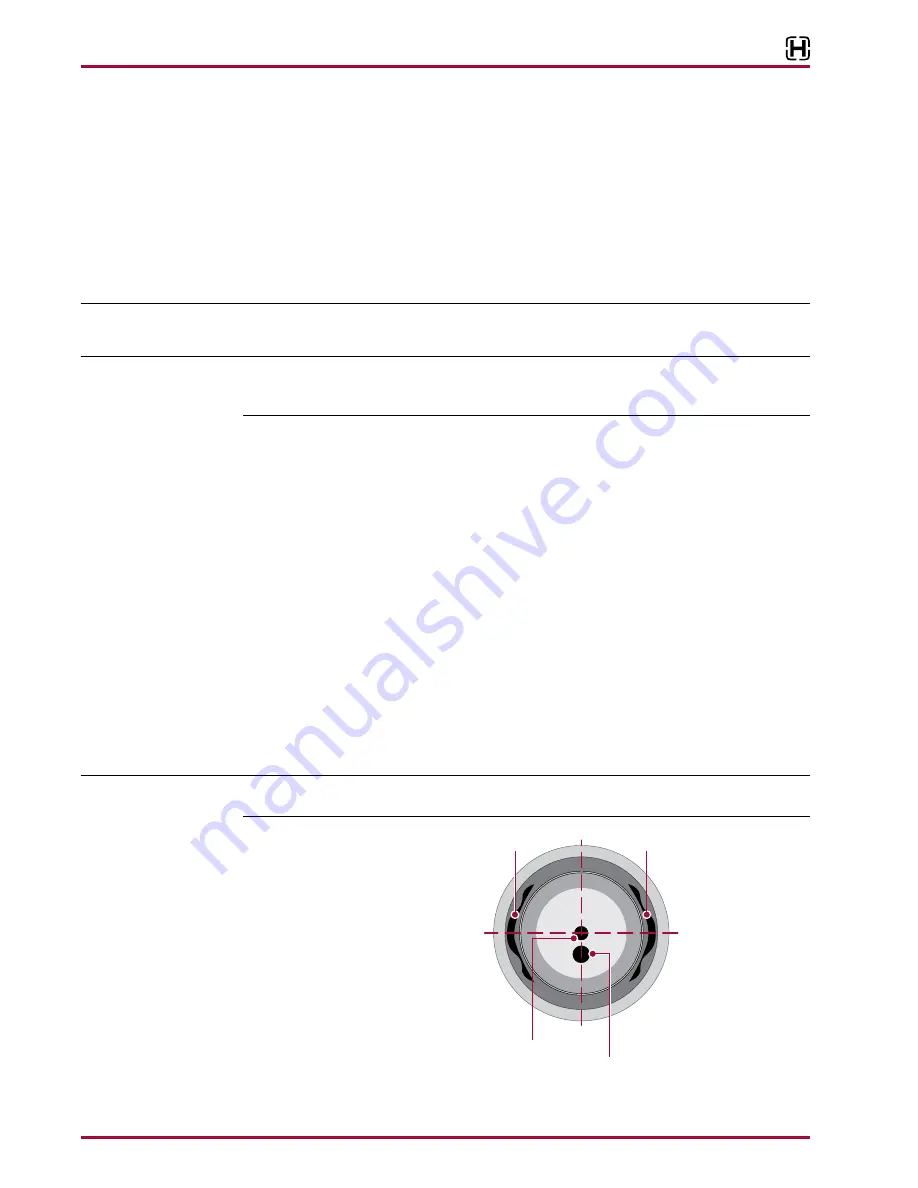

CENTER BUSHINGS

VISUAL INSPECTION

An inspection of the center bushing is necessary

when a vehicle is in the shop for major repair

work

and at regular preventive maintenance intervals .

NOTE

ULTIMAAX center bushing is designed with voids at front and rear, see Figure 6-1 . These voids are

not an indication of wear .

FIGURE 6-1

1 . Visually inspect the center bush-

ing for signs of movement or

excessive wear such as frayed,

bulging or distorted rubber in the

center bushing .

2 . Replacement is necessary if:

■

Any metal to metal contact is

visible .

■

Any signs that the bushing

inner metal is not centered in

the bushing .

■

Any equalizing beam to sad-

dle contact .

CL

Void

Void

Center

Hole

Verify the voids are

perpendicular to the

horizontal centerline

and the second locating

hole is on the bottom

Horizontal Centerline

Second Locating

Bottom Hole