Preventive Maintenance

16

17730-299

ULTIMAAX

®

for Fire and Rescue Vehicles

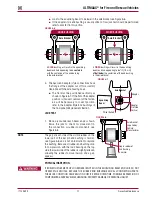

FIGURE 6-4

JACK TEST

1 . Place a jack under each beam end as shown . Raise the

jack to check for movement in the connection or rubber

components, see Figure 6-4 .

NOTE

The gap at each side of the visible rubber on the lower

part of the end bushing is normal, see Figure 6-4, and is

not an indication to replace the bushing . Because all rubber

end bushings are in compression, with the load bearing on

the top side, the lower side of the rubber is slightly relieved,

allowing the rubber to move inward, and a gap appears .

PHYSICAL INSPECTION

IF BAR PIN MOVEMENT OR LOOSENESS IS NOTED IN ANY OF

THE EQUALIZING BEAM END HUBS, DO NOT OPERATE THE VEHICLE . REPLACE THE RUBBER END

BUSHINGS AND ALL CONNECTING PARTS IF NECESSARY . THE ABOVE CONDITION CAN RESULT

IN COSTLY REPAIR, DOWNTIME, POSSIBLE SEPARATION OF COMPONENTS, ADVERSE VEHICLE

HANDLING, PROPERTY DAMAGE, OR PERSONAL INJURY .

SERVICE HINT

An equalizing beam end connection that is visibly cleaner than the other connections may indi-

cate a loose connection .

2 . If bar pin end bushing movement or looseness is detected in the equalizing beam end hub,

replace the end bushings and all connecting parts . Refer to the Component Replacement

Section of this publication .

3 . Check and record torque values, as received, for each 1" bar pin fastener, see Figure 6-2 .

Ensure all fasteners are tightened to:

■

At the

locknut

to 525 ± 75 foot pounds torque, or

■

At the

bolt head

to 575 ± 75 foot pounds

4 . R e c h e c k e q u a l i z i n g beam end connections for signs of looseness .

■

Inspect alignment shims in equalizing beam end for looseness . Lightly tap on the align-

ment shims to see if they can be moved . If movement is detected, tighten fasteners to the

proper torque value, see Figure 6-2 .

■

Inspect equalizing beam end connection for signs of excessive wear or looseness .

5 . If bar pin looseness is still detected in any of the equalizing beam end hub,

DO NOT

operate

the vehicle . One or more components will require replacement, see Component Replacement

Section of this publication .

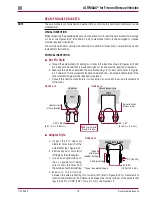

■

Adapter Style,

see Figure 6-5

FIGURE 6-5

VISUAL INSPECTION

1 . Chock the wheels .

2 . Visually inspect suspension

components for signs of

movement or excessive wear .

■

Inspect the equalizing

beam end connection

for signs of excessive

wear or looseness .

■

Look for worn, frayed or

distorted rubber in the beam, see Figure 6-6 .

Axle Bracket

Gap in rubber

of bar pin end

bushing is

normal

Floor

Jack

Equalizing

Beam

Adapter Style

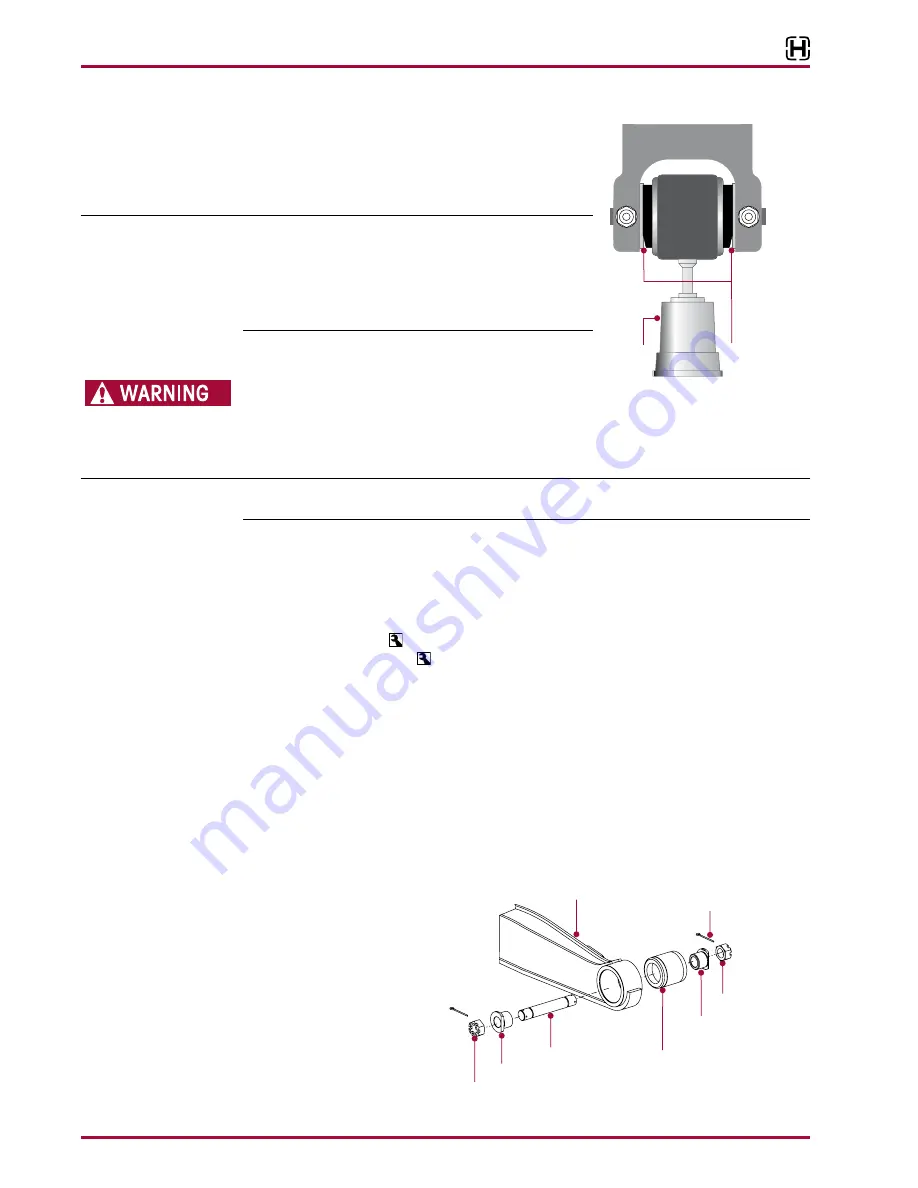

End Bushing

Beam End Adapter

Beam End Shaft

1 / " Slotted Nut

7

8

Beam End Adapter

1 / " Slotted Nut

7

8

Cotter Pin

63K Shown

ULTIMAAX