17730-299

29

Alignment & Adjustments

ULTIMAAX

®

for Fire and Rescue Vehicles

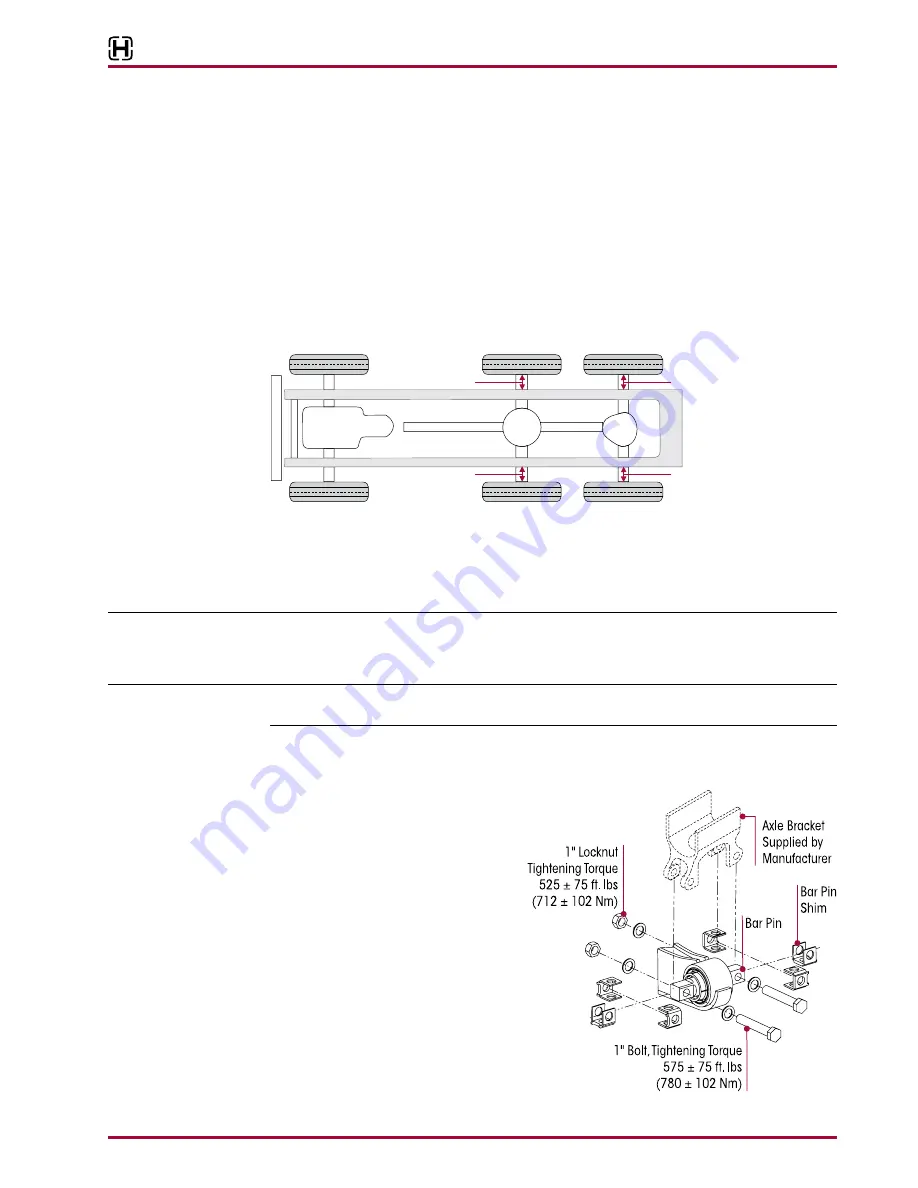

AXLE LATERAL ALIGNMENT

1 . Use a work bay with a level floor .

2 . Drive the vehicle slowly, straight ahead . Try to slacken or loosen the suspension as the vehicle

is positioned . End with all wheels positioned straight ahead . Try to roll to a stop without the

brakes being used .

DO NOT

set the parking brake .

3 . Chock the front wheels of the vehicle .

4 . Measure from the outside of the frame rail to the rim flange of the inner tire . Record the mea-

surement

A

and

B

, see Figure 7-3 .

5 . Measure the same distance on the opposite side of the same axle . Record the measurement

C

and

D

, see Figure 7-3 .

FIGURE 7-3

6 . Verify the axle lateral alignment is within the vehicle manufacturer’s specifications . Adding

or removing shims that are located between the transverse torque rod and the frame rail will

normally correct the axle lateral alignment .

■

A general rule of thumb is to use a torque rod shim with a thickness that is half of the dif-

ference between the two measurements .

EXAMPLE

If the axle lateral alignment is out of specification by ¼" (6 mm), remove or install a

1

⁄

8

" (3 mm)

torque rod shim between the transverse torque rod and frame rail as needed . Refer to Longitudinal

and Transverse Torque Rod Section in Preventive Maintenance Section of this publication .

NOTE

Hendrickson recommends the use of Grade 8 bolts and Grade C locknuts . Washers are not neces-

sary when flanged fasteners are used .

BAR PIN ALIGNMENT

FIGURE 7-4

The alignment feature consists of spe-

cially designed, tightly tolerance steel

shims which fill the

3

⁄

8

" (9 .5 mm) total

gap between the bushing’s bar pin and

the axle bracket legs . The gap must be

filled by placing the shims on the bushing

assembly in one of the positions shown

in Figure 7-4 . Hendrickson has three shim

designs options for alignment, part num-

ber 50130-000 (provided), 50131-000

and 57026-000, see Figure 7-7 .

FRONT

A

B

C

D

▲