Component Replacement

48

17730-299

ULTIMAAX

®

for Fire and Rescue Vehicles

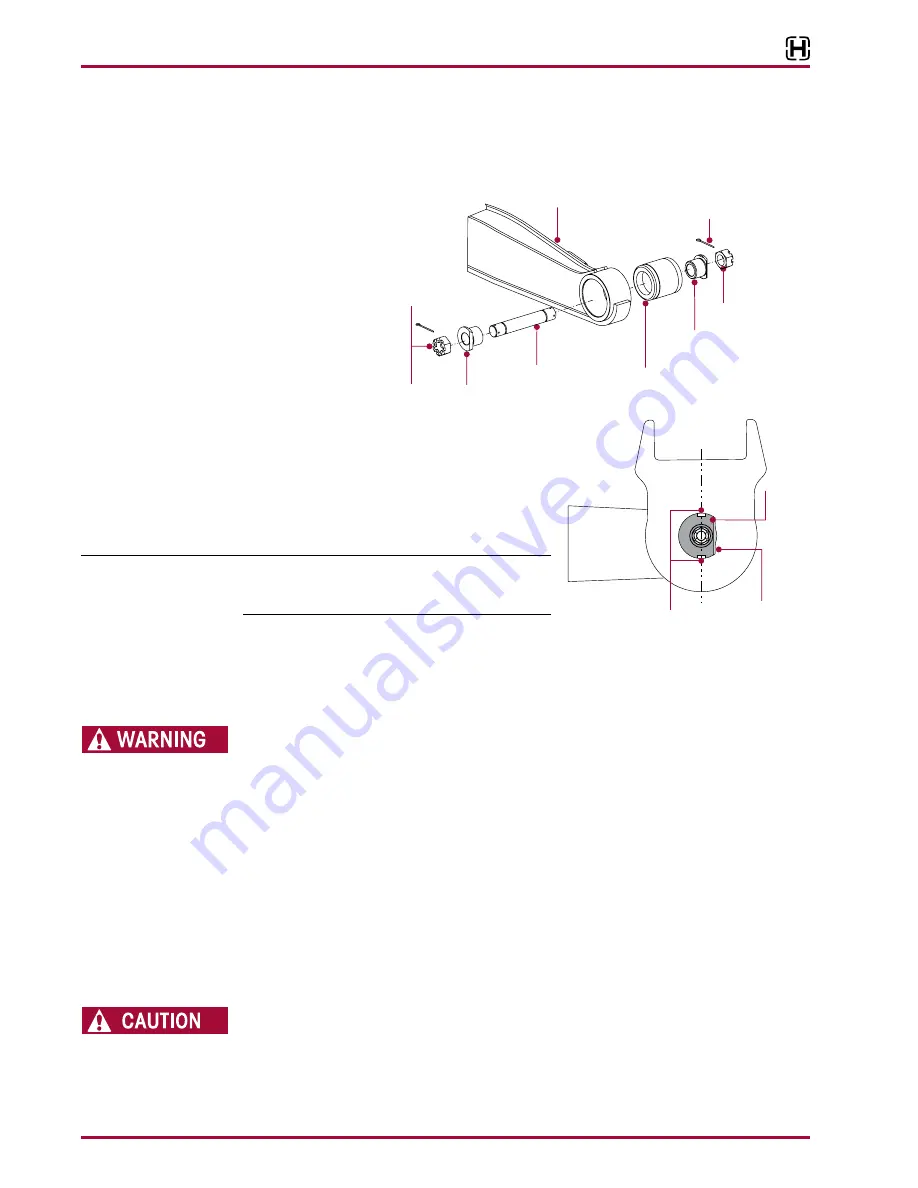

5 . Apply hydraulic force and press the new bushing into place . The bushing will be completely

seated when the clamp makes contact with the beam face .

6 . Install one adapter through the axle bracket leg at the wheel side, into the beam end bushing,

see Figure 8-40 .

FIGURE 8-40

FIGURE 8-41

7 . Install the other adapter through the axle bracket

leg at the axle side, taking advantage of the cut-

off flange on the adapter to clear the axle .

8 . Insert adapter connections, see Figure 8-41 .

9 . Rotate the adapters so the adapter cut off flats

are vertical as shown in Figure 8-41 .

NOTE

Axles must be in operational position before fasten-

ers are tightened to prevent pre-loading of the rubber

bushing .

10 . Assemble one slotted nut to the shaft and install the cotter pin . Place a suitable wrench on the

nut and ensure the wrench is locked in place (braced) to prevent movement . Tighten using

one of the following torque procedure .

TORQUE PROCEDURE

IF THE RECOMMENDED TORQUE VALUE IS NOT PROPERLY MAINTAINED, THE METAL SURFACES OF THE

AXLE BRACKET LEGS, HOLES, ADAPTERS AND RUBBER BUSHING INNER METALS CAN EXPERIENCE

EXCESSIVE WEAR AND/OR FAILURE . THIS CAN CAUSE SEPARATION OF COMPONENTS AND ADVERSE

VEHICLE HANDLING, PROPERTY DAMAGE OR PERSONAL INJURY .

A simple torque wrench will not be sufficient to obtain the proper torque requirement . The proper

torque requirement can be obtained with the use of a torque multiplier . If one is not available the

use of a slug wrench is recommended .

METHOD A:

TORQUE MULTIPLIER

You will need:

■

Torque Multiplier

a . Assemble the opposite nut and use a torque wrench with multiplier .

b . Tighten the nut to torque multiplier value 700 ± 50 Foot Pounds torque, see Table 1 .

DO NOT BACK OFF NUT TO INSTALL COTTER PIN, DOING SO MAY REDUCE THE TIGHTENING TORQUE

BELOW THE REQUIRED SPECIFICATION .

c . Install cotter pin . The nut may be advanced to the next nut slot .

DO NOT

back off nut .

Equalizing Beam

Adapter Style

End Bushing

Beam End Adapter

Beam End Shaft

1 / " Slotted Nut

7

8

Beam End Adapter

1 / " Slotted Nut

Tightening Torque

125 ft. lbs. (170 Nm)

+ 90° rotation or

700 ± 50 ft. lbs. (949 ± 68 Nm)

7

8

Cotter Pin

63K Shown

ULTIMAAX

Axle Bracket

Adapter

Equalizing

Beam

Adapter

Flat Side

Vertical

Chisel Reliefs