17730-299

13

Preventive Maintenance

ULTIMAAX

®

for Fire and Rescue Vehicles

SECTION 6

Preventive Maintenance

Following appropriate inspection procedures is important to help ensure the proper maintenance

and operation of the suspension system and component parts . Hendrickson recommends the

ULTIMAAX rear suspension be inspected at pre-delivery, the first in-service inspection and regu-

lar preventive maintenance intervals . Off-highway and severe service operating conditions may

require more frequent inspections than on-highway or less severe service operations . Inspection

must include the following items and other components referenced in this section .

NOTE

Torque values shown in this publication apply only if Hendrickson supplied fasteners are used . If

non-Hendrickson fasteners are used, follow the torque specification listed in the vehicle manufac-

turer’s service manual .

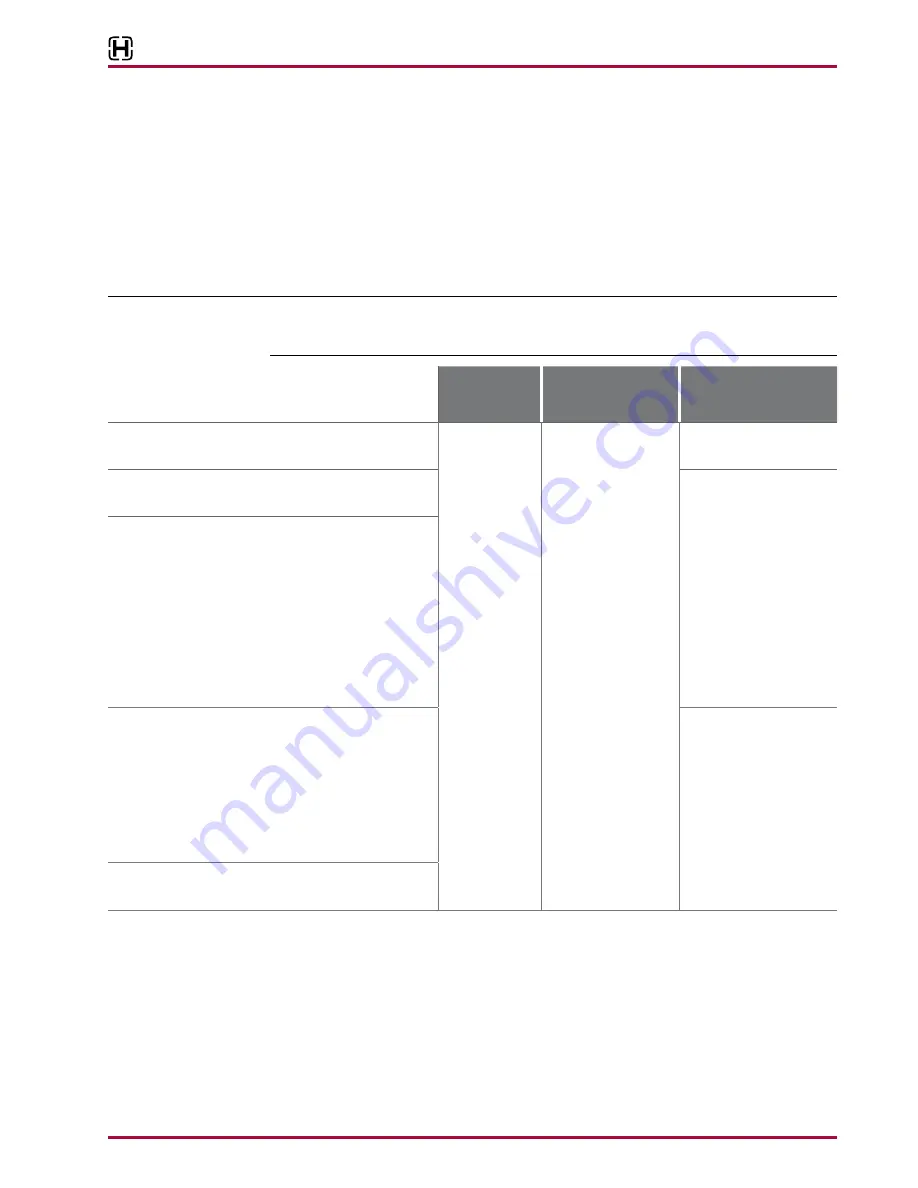

HENDRICKSON RECOMMENDED

INSPECTION INTERVALS

PRE-DELIVERY

INSPECTION

FIRST IN-SERVICE

INSPECTION

PREVENTIVE

MAINTENANCE

Inspect Progressive Load Spring

Within the first

500 Miles

(500 km)

Within the first

1,500 Miles

(2,000 km) or

100 Hours

Every 3 Months /

600 Hours

Inspect torque rods and equalizing beam end

connections

Every 6 Months /

1200 Hours

or

25,000 Miles /

40,000 km

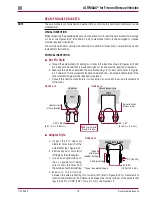

Visually Inspect proper assembly and function . Check

for all of the following and replace components as

necessary:

• Signs of unusual movement, loose or missing

components

• Signs of abrasive or adverse contact with other

components (example: brake lines, wheel wells,

frame hangers, etc .)

• Damaged, or cracked parts

• Proper suspension function, alignment

Inspect fasteners for proper torque as recommended

in the Torque Specification Section of this publication

with special attention to the following suspension

connections:

• Equalizing beam end connection

• Saddle cap connection

• Frame hanger to frame rail connection

• Center Bushing

Every 12 Months /

2400 Hours

Verify the alignment of axles are within the vehicle

manufacturer’s tolerances .

COMPONENT INSPECTION

Following appropriate inspection procedures is important to help ensure the proper maintenance

and operation of the ULTIMAAX heavy-duty rear suspension system and component parts . Look for

and replace worn, damaged, bent or cracked parts .

■

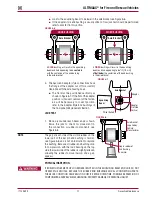

Cross tube —

Clean the cross tube and inspect it for cracks or excessive wear 8" to 10" from

each end where it enters into the equalizing beam center bushings . Use a straight edge to

check the straightness of the cross tube . If there is a doubt as to fracture, wear or straightness,

replacement is necessary .