17730-299

15

Preventive Maintenance

ULTIMAAX

®

for Fire and Rescue Vehicles

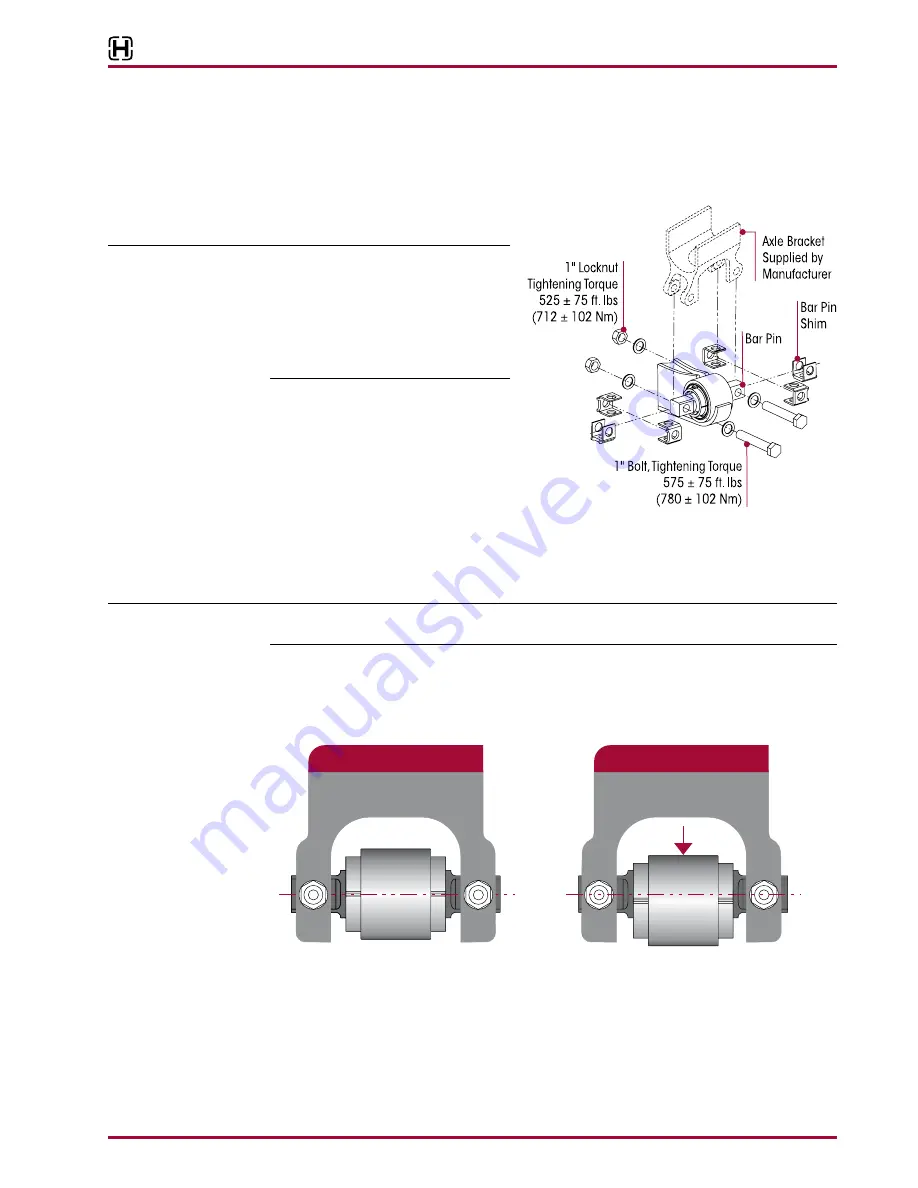

EQUALIZING BEAM END CONNECTION

An inspection of the beam end connections are necessary

when a vehicle is in the shop for

major repair work

and at regular preventive maintenance intervals . Periodic visual inspection by

the driver and service personnel is also recommended .

FIGURE 6-2

■

Bar Pin Style,

see Figure 6-2

NOTE

The equalizing beam end connection

requires that the fasteners are tightened

to torque specifications, see Figure 6-2,

to maintain the clamp load of the axle

bracket legs to the bar pin . All bushing

motion is accommodated by rubber

deflection .

VISUAL INSPECTION

1 . Chock the wheels .

2 . Visually inspect suspension com-

ponents for signs of movement or

excessive wear .

■

Inspect alignment shims in

equalizing beam end for looseness . Lightly tap on the alignment shims to see if they

can be moved . If movement is detected, tighten fasteners to the proper torque value, see

Figure 6-2 .

■

Inspect the equalizing beam end connection for signs of excessive wear or looseness .

SERVICE HINT

An equalizing beam end connection that is visibly cleaner than the other connections may indi-

cate a loose connection .

■

Look for worn, frayed or distorted rubber in the bar pin beam end bushing, see Figure 6-3 .

■

Look for the equalizing beam to be lower in the beam hanger, see Figure 6-3 .

■

If the bar pin beam end bushing is visually offset a floor jack test should be performed,

refer to Jack Test in this section .

FIGURE 6-3

Axle Bracket

Axle Bracket

GOOD BUSHING

WORN BUSHING

C

L

C

L

A

bushing will result in the equalizing beam

GOOD

end hub appearing to be

with the

centered

centerline of the end bushing in the axle bracket

A

bushing will result in the equalizing beam

WORN

end hub appearing to be / " (15 mm)

5

8

offset/below

the centerline of the end bushing in the axle bracket