17730-299

19

Preventive Maintenance

ULTIMAAX

®

for Fire and Rescue Vehicles

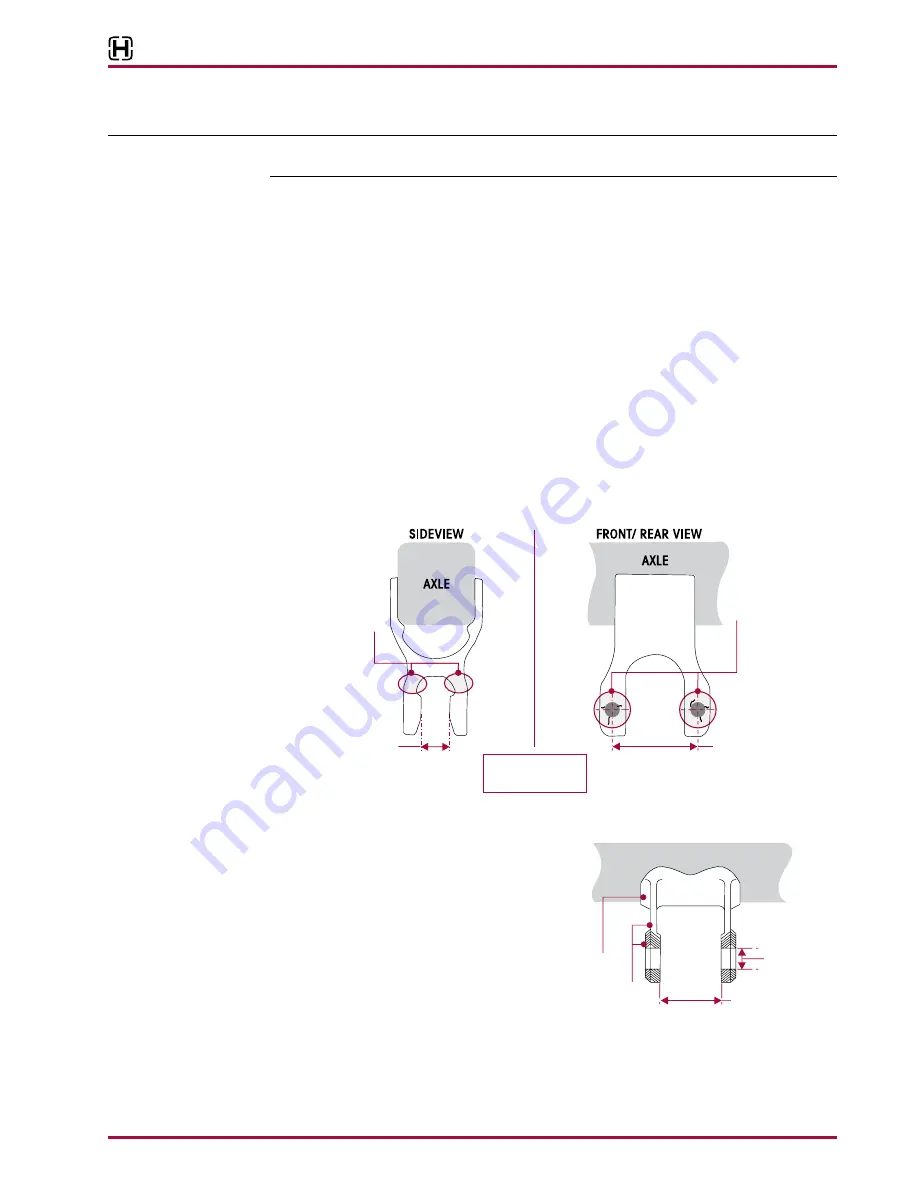

BEAM END AXLE BRACKETS

NOTE

The axle brackets are furnished and welded into position by the vehicle manufacturer or axle

manufacturer .

VISUAL INSPECTION

When inspecting the equalizing beam end connection also inspect the axle brackets for damage

or cracks, see Figures 6-12, 6-13 and 6-14 . Any axle bracket that is found damaged or cracked

must be repaired or replaced .

Consult the axle and/or vehicle manufacturer for additional inspections, component repair and

replacement instructions .

PHYSICAL INSPECTION

■

Bar Pin Style

a . Inspect the axle brackets for damage or cracks in the locations shown in Figures 6-12 and

6-13 . Any axle bracket that is found damaged or cracked must be repaired or replaced .

b . Measure the distance between the axle bracket legs for correct width, refer to Figures

6-12 and 6-13 for measurement location and dimensions . An axle bracket outside of the

measurement range must be repaired or replaced .

c . Consult the vehicle manufacturer for inspection, component repair and replacement

instructions

FIGURE 6-12

FIGURE 6-13

■

Adapter Style

FIGURE 6-14

a . Inspect the 2½" (64 mm)

diameter holes in each of the

axle bracket legs, Figure 6-14 .

b . Remove any burrs or material

left there by the old adapters .

c . Use a new adapter style bush-

ing as a gauge for fit, being

sure it enters the holes from

the outside of each bracket leg .

d . M e a s u r e t h e d i s t a n c e

between the axle bracket legs for correct width, refer to Figure 6-14 for measurement

location and dimensions . The dimension between the inside surfaces of the axle bracket

legs is 6 .015" ± 0 .005" (152 .7 mm ± 0 .1 mm), see Figure 6-14 .

Typical location

of crack areas

8.5" ± 0.1"

(216 mm ± 2.6 mm)

Look for cracks

in these locations

2.29" ± 0.025"

(58.11 mm ± 0.63 mm)

NOTE:

Typical axle

brackets shown

Axle

2½" (64 mm)

*Standard

Axle Bracket

(Rubber Bushing)

ADAPTER STYLE AXLE

*Typical axle bracket shown

Axle Bracket Leg

6.01/6.02"

(152.6/152.8 mm)