17730-299

21

Preventive Maintenance

ULTIMAAX

®

for Fire and Rescue Vehicles

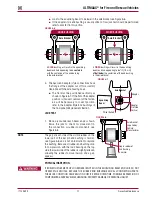

FIGURE 6-18

■

Bonding separation of the rubber from any of the

bonded rate plate surfaces to a maximum depth

of approximately 2" (50 mm) is acceptable, see

Figure 6-18 . If the bonding separation depth is

2" (50 mm) or more, the shear springs require

replacement .

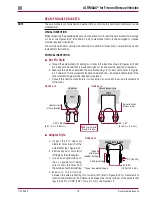

■

A certain amount of gradual breakup of the rubber sur-

face is acceptable . Use a feeler gauge to measure cuts

or splits in the rubber . If the measurement is over a

depth of 2" (50 mm), then the shear springs require replacement, see Figures 6-19 and 6-20 .

FIGURE 6-19

FIGURE 6-20

FIGURE 6-21

PROGRESSIVE LOAD SPRINGS (PLS)

NOTE

Hendrickson Lit. No. 48422-592

– ULTIMAAX Gauge

Card (Figure 6-21) can be used to measure in the

unloaded condition the height of the progressive load

spring (PLS), plus the length of cuts / splits and depth of

separation of the shear spring and the PLS .

Visually inspect the progressive load springs at

regular preventive maintenance intervals . The follow-

ing points are for guidance and intended to assist

personnel in determining when progressive load spring

component requires replacement, refer to the Component

Replacement Section of this publication .

NOTE

The Hendrickson ULTIMAAX suspension progressive load

springs must be replaced in pairs (left side pairs or right

side pairs or rear position pairs or front position pairs),

even if only one PLS shows unacceptable conditions .

Replacement of only one PLS can cause uneven wear,

and higher premature wear for the one replaced

■

Always inspect the progressive load spring with the

vehicle in the

UNLOADED

condition .

■

The height of a new PLS is 3

1

⁄

16

" (78 mm) . The PLS requires replacement if the height is below

2

5

⁄

16

" (59 mm), see Figure 6-22 .