Preventive Maintenance

22

17730-299

ULTIMAAX

®

for Fire and Rescue Vehicles

■

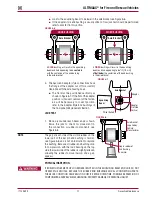

A bent or cracked mounting base requires PLS replacement .

FIGURE 6-22

FIGURE 6-23

■

If any cuts or splits in the rubber of over 2" (50 mm) in length

and an average depth of ½" (13 mm), the effected PLS

requires replacement . A certain amount of gradual breakup

of the rubber surface is normal . The most probable areas for

potential cuts, splits, or wear are shown in Figure 6-22 as

“

/ / / / / / /

.”

■

The

bonding

separation

depth

of the rubber from the PLS

mounting base plate surface (see Figure 6-22) is more than

½" (13 mm), the effected PLS requires replacement .

■

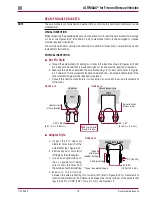

Creases formed by folding of the rubber surface under load

are acceptable . These appear as stripes on the surface, pol-

ished by wear or covered with tacky rubber, see Figure 6-23 .

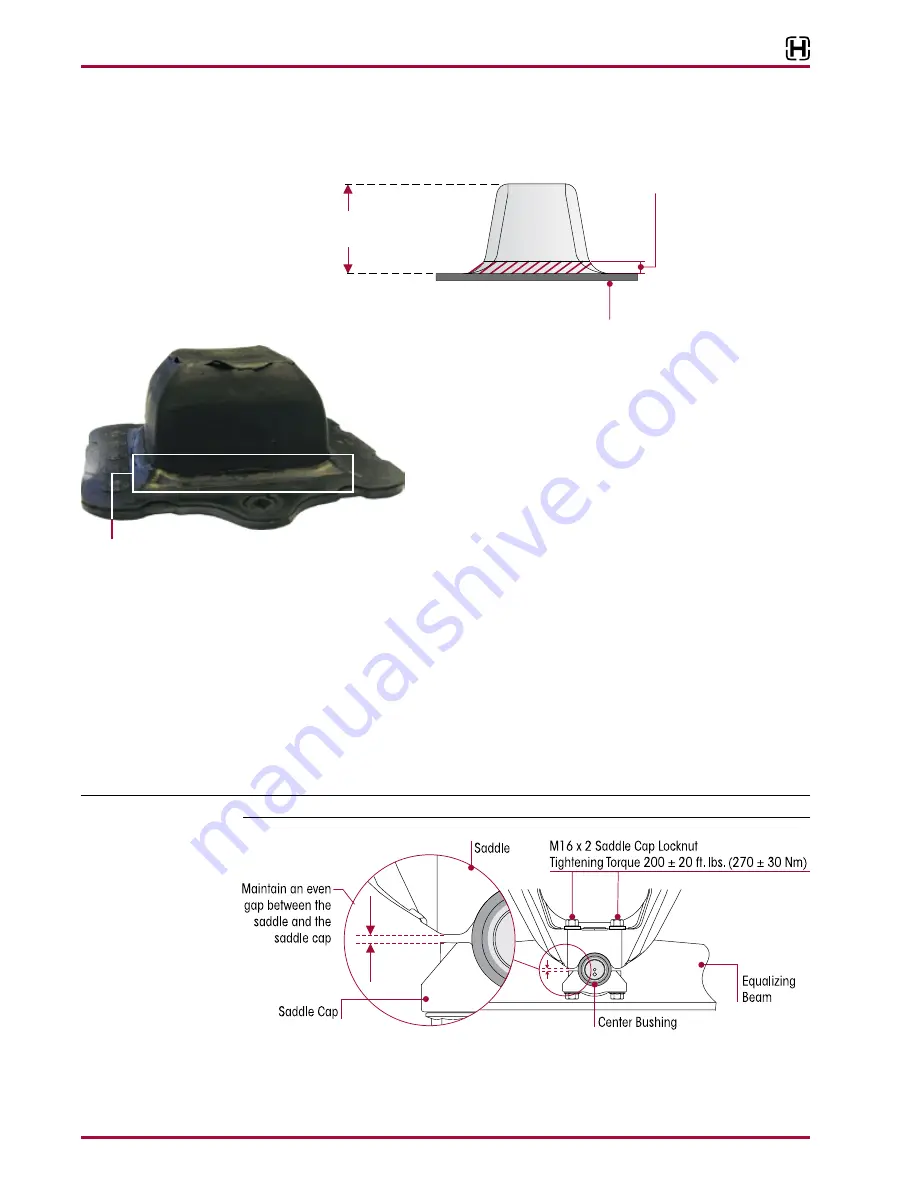

SADDLE CONNECTION

Visually inspect for any signs of movement or looseness and ensure:

■

Each saddle is centered on each equalizing beam center bushing .

■

The center bushing inner metal is fully seated to the saddle .

■

Saddle cap locknuts are tightened to proper torque as specified in the Torque Specifications

Section of this publication .

Saddle cap fasteners

— While tightening the saddle cap fasteners maintain an even gap

between the saddle and saddle cap, see Figure 6-24 .

NOTE

Tightening the saddle cap fasteners properly will help prevent wear of mating components .

FIGURE 6-24

PLS height when new 3.1" (78 mm)

Minimum acceptable height 2.3" (59 mm)

Replacement required if PLS height

is less than

2.3" (59 mm)

Progressive Load Spring (PLS) Height

in the Unloaded Condition

Inspection area

for any cuts,

splits, or bonding

separation

Mounting

Base

Progressive Load Spring

Polished Appearance

—

Creases formed by the folding of

the rubber surface under load are acceptable.