Preventive Maintenance

24

17730-299

ULTIMAAX

®

for Fire and Rescue Vehicles

TORQUE RODS

THE ULTIMAAX SUSPENSION INCORPORATES TORQUE RODS FOR VEHICLE STABILITY . IF THESE

COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL THE VEHICLE SHOULD NOT BE

OPERATED . FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING AND POSSIBLE TIRE

CONTACT WITH THE FRAME OR THE SUSPENSION .

Visually inspect torque rod bushings

for any torn or shredded rubber, inspect for bent, cracked,

or broken torque rods, and for end hubs with any elongated “oval” shape . Any of these conditions

will require component replacement .

Torque rod looseness

inspection is necessary per the following method below .

■

With the vehicle shut down, a lever check can be made with a long pry bar placed under each

rod end and pressure applied .

TORQUE ROD LENGTH

Longitudinal torque rod

length is determined by the vehicle manufacturer for optimum drive-

line angles . The longitudinal torque rods maintain these angles and control acceleration and

brake forces .

Transverse torque rod

length is also determined by the vehicle manufacturer to center the axles

under the frame .

■

If the lateral alignment of the axles is incorrect, it may be necessary to shim the transverse

torque rod at the straddle mount end . Shims can be installed between the transverse torque

rod and the transverse torque rod frame bracket or between the transverse torque rod and

axle tower bracket . Refer to vehicle manufacturer for proper shim location; also see Lateral

Alignment in the Alignment & Adjustments Section of this publication .

■

The transverse torque rods also control axle walk-out during cornering . The mounting brackets

at the axle housing end of the torque rods are furnished and welded into position on the axle

housings by the axle or vehicle manufacturer .

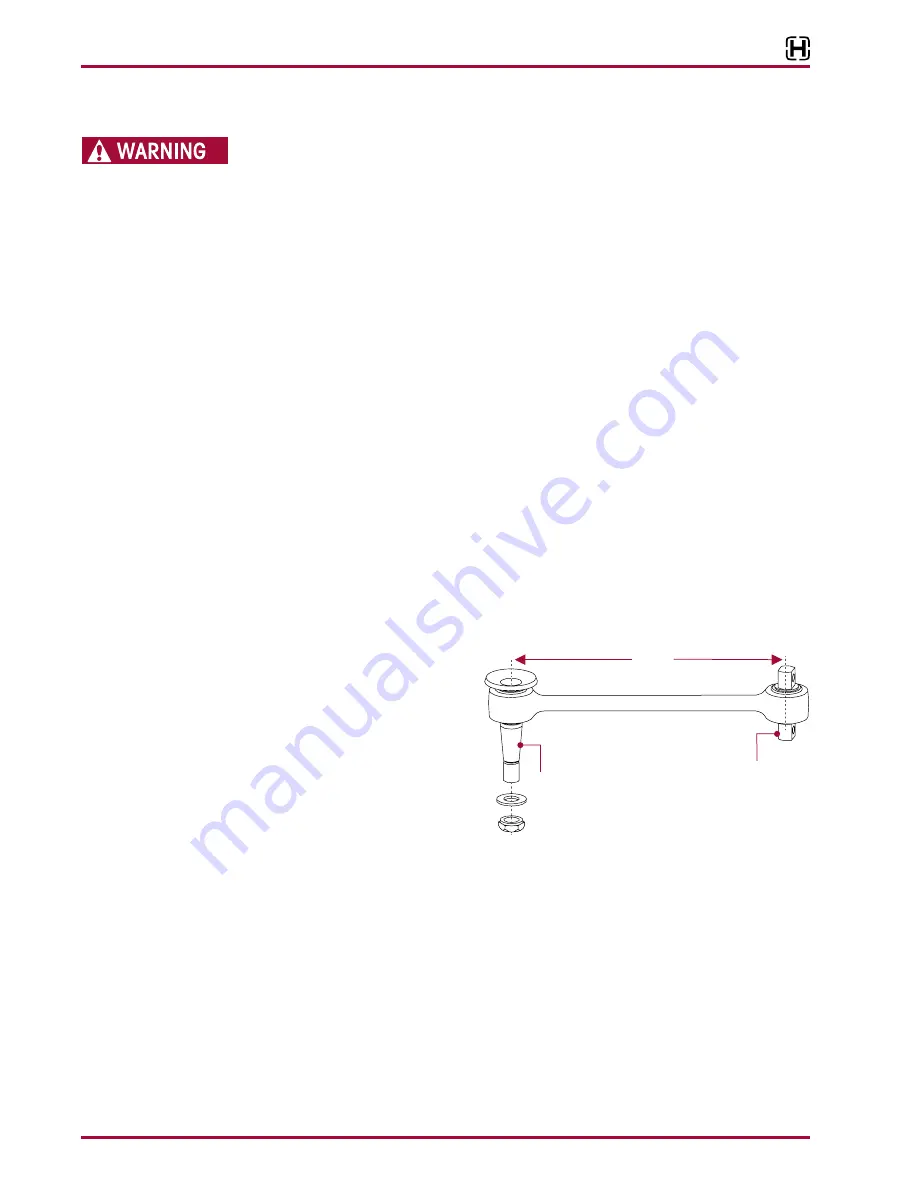

FIGURE 6-26

Transverse and longitudinal torque

rods

have attaching ends desig-

nated as “straddle mount,” or “tapered

stud” as shown in Figure 6-26 . Most

can be replaced by pressing out the

worn torque rod bushing and install-

ing a replacement bushing, others

require complete torque rod assembly

replacement .

It is important that the tightening

torque of the nuts be checked during preventive maintenance service . Follow the vehicle manu-

facturer’s specifications for tightening torque values .

The tapered stud torque rod locknuts also should be checked . Refer to the Torque Specification

Section of this publication for proper torque values .

Length

Tapered Stud

Straddle Mount