17730-299

33

Component Replacement

ULTIMAAX

®

for Fire and Rescue Vehicles

SHEAR SPRING / FRAME HANGER ASSEMBLY / SADDLE ASSEMBLY

You will need:

■

Saddle Disassembly Tool

No . 66086-113L and

Saddle Assembly Tool

No . 66086-108L,

refer to the Special Tools Section of this publication .

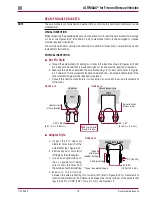

FIGURE 8-2

DISASSEMBLY

1 . Chock the front wheels of the vehicle .

2 . Raise and support the drive axles .

3 . Remove the drive tires from the side of the

vehicle being serviced .

4 . Remove and discard the M16 saddle cap

fasteners that attach the saddle assembly to

the center bushing, see Figure 8-2 .

5 . Raise the vehicle’s frame just enough to create a ½" (13 mm) gap between the saddle assem-

bly and center bushing . Support the vehicle’s frame at this height .

6 . Remove the progressive load springs M10 fasteners and discard, see Figure 8-4 .

7 . Remove the progressive load springs .

8 . Apply NLGI #2–EP (Extreme Pressure) chassis lubricant to the threaded rod of the saddle

disassembly tool, No . 66086-113L, see Figure 8-3 .

FIGURE 8-3

FIGURE 8-4

NOTE

The threaded rod spacer and spacer nut are designed and orientated to fit into the saddle assem-

bly openings, see Figure 8-5 .

9 . Install both saddle disassembly tools on each end of one saddle assembly, rotate the threaded

rod blocking nuts until each are oriented properly into the saddle assembly openings, see

Figures 8-4 and 8-5 .

FIGURE 8-5

M16 Saddle Cap

Fasteners

Saddle

Saddle Cap

Center

Bushing

Saddle Disassembly Tool

Hendrickson Part No.66086-113L

Threaded

Rod Nut

Blocking

Nuts

Apply

#2–

(Extreme Pressure) chassis lubricant

NLGI

EP

Threaded Rod

Blocking Nuts

Saddle Disassembly Tool

Hendrickson Part No. 66086-113L

Saddle Assembly

Opening