7

2 Description

2.2 Theory of Operations

The Benchtop Peristaltic Dispenser transfers low viscosity liquids by pressure

displacement applied by a turning rotor against a tube carrying the material. Usually

these pumps are chosen because the liquids are hazardous or difficult to work with

and it is advisable to limit operator contact. Another reason is that peristaltic pumps

are air free.

Dispense outputs can be timed from 0.01 - 99.99 seconds with flow speeds from

0.01-6 ml/min using PTFE tubing. The pump is bi-directional allowing suck-back

after dispense to prevent dripping of the fluid.

When dispensing UV adhesives use only black tubing. This avoids curing of the

adhesive in the tube.

The amount of product dispensed is controlled by:

– The dispensing time.

– The size of the used feedline.

– The speed of the drive.

– The size of the dispensing needle.

Various sizes of PTFE tubes, the corresponding applicator nozzles and dispensing

needles are available, see section 7.1.

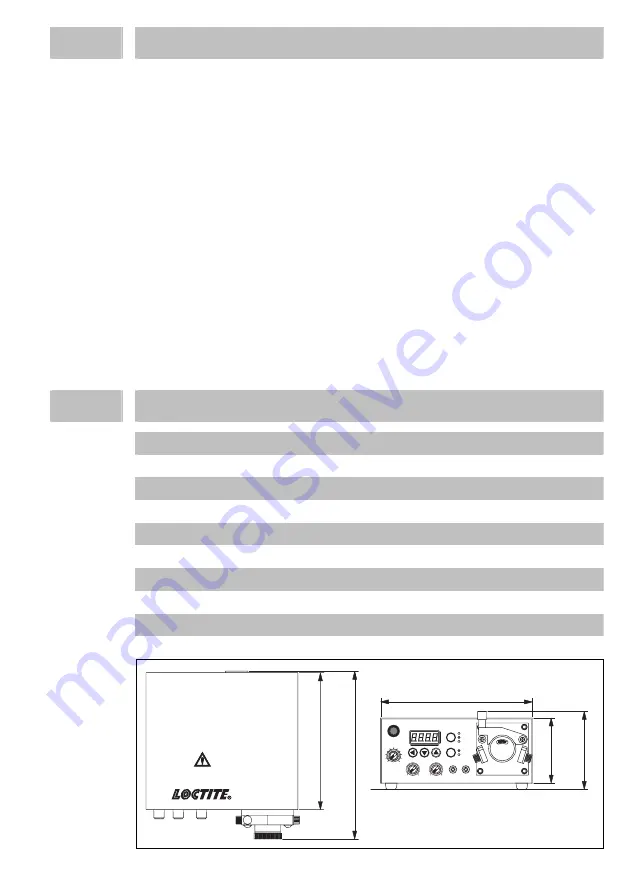

3 Technical Data

Power supply

100-240 V AC ± 10%, 50/60 Hz

Power Consumption

~0.3 A

Fuse

T1A fast-acting (Glass type, 5 x 20 mm)

Dispensing time range

0.01 - 99.99 sec

Rotor speed

Up to max. 120 rpm (CW/CCW)

Flow rate

0.01 - 6 ml/minute with feedline

Direction of rotation of the drive Clockwise (CW) - Counterclockwise (CCW)

Operating Temperature

+5°C - +50°C (+41°F -122°F)

Relative Humidity

Max. 80%

Weight

~3

kg

prior to removing cover.

Unplug power cord

WARNING:

98548

TIMER

CONT.

R.C

CW

CCW

MODE

VACUUM

0

SPEED

0

10

POWER

4

2

6

8

V.INT

10

0

10

OUT

DRIV

TIME DISPLAY

IN

190 mm

7.46"

81 mm

3.2"

98 mm

3.85"

171 mm

6.73"

210 mm

8.25"