Important: Always read and follow the information box instructions.

• 17

Machine Calibration

Calibration

1.

Mount a 14, 15, or 16-inch steel tire/wheel assem-

bly on the balancer. A balanced tire/wheel is required.

Note:

Position wheel so that no weights on either

flange are at the top-dead-center location. Turn the

machine OFF then ON.

2.

Enter DIMS (A, W, and D wheel dimensions).

3.

Press and hold the SHIFT key and press 1 to select

the CAL MACHINE mode.

4.

Lower the hood and press START.

5.

After spin, raise the hood. Rotate wheel until the

right plane center bar blinks; attach test weight to the

outside flange at top-dead-center: 4-ounce (100 grams)

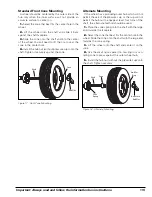

Figure 19 - Test Weight On Outside Flange At Top-Dead-Center

6.

Lower the hood and press START.

Important:

It is critical that the inner weight be

placed accurately to achieve proper calibration. If the

test weight is not moved from the outside flange

directly across to the inside flange an inner weight

placement error will occur. To correct, follow the infor-

mation box instructions.

7.

After spin, raise the hood. Rotate wheel until the

left plane center bar blinks; move and attach test

weight to the inside flange at top-dead-center: 4-ounce

(100 grams)

Figure 20 - Test Weight Moved (Directly Across) To Inside

Flange

8.

Lower the hood and press START.

9.

Calibration complete. Press NEXT.

Maintenance Instructions

The balancer requires only minor maintenance to

keep the unit operating properly.

1.

Keep the display clean and clear. Use a damp

cloth. Do not use cleaners or solvents which leave oily

or filmy residues behind.

2.

Keep the adapters, cones, faceplate, threaded

shaft, pressure cup, and hub nut clean. Grease and dirt

buildup will cause inaccurate balancing and premature

wear. Clean these items at least once a day with a

vaporizing solvent.

3.

Clean weight tray and any accessory posts, pegs,

or storage shelves with a vaporizing solvent. Weights

stored in a dirty tray may pick up grease and dirt which

may keep them from securely attaching to the wheel.

Use common sense, this is an electrical

device. Exposing the balancer to water,

either by hose or bucket, or by exposure to

rain or snow, may cause risk of shock or

electrocution to operator or bystanders.

Place, store, and operate the balancer only

in a dry, sheltered location.

Do not hose down with water or bucket

wash the balancer. Extensive damage to the

balancer will result. Sensitive electronic

components, wiring harnesses, and other

devices housed in the balancer are not

intended to be exposed to water.

4.

Keep the area around the balancer clear. Remove

any tools or other items that are leaning against the

balancer. Keep the area under the balancer clear.

Remove any items that may cause the balancer to not

sit level. Be particularly cautious of new or used wheel

weights on the floor, as they may cause personal injury

due to falls.

5.

To replace Arm Laser battery, remove cap. Discard

old batteries. Install two new batteries, plus side up.

Replace cap.

CAUTION

WARNING

Arm

Laser

Case

Cap

Arm Laser

Batteries

A&D Arm