Performance Tires/Custom Wheels

Before You Begin - Pre-Operation Notes

Only tire technicians with training on custom

wheels should attempt to service expensive

custom alloy or aluminum wheels and high

performance low-profile tires.

•

Ensure all weights have been removed from

the wheel before servicing.

•

Assistance will be required on wide wheels.

•

Use ample lubricant during mounting and

demounting operations.

•

Always review wheel nicks and/or scratches

with the owner before servicing.

1.

Check the clearance on the lower bead

loosener shoe. If it does not clear the rim lip,

install the 1/4” shim (figure 17).

To Install the Shim: Remove the tire/wheel

assembly from the tabletop and depress the

foot pedal. The loosener shoe will extend to

the top of it’s stroke. Do not release the pedal.

Tilt the bead loosener shoe away from the

center post and slip the red 1/4” thick shim

over the end of the bolt between the shoe

adjusting bar and the lower shoe.

Figure 17- Installing 1/4” Shim

2.

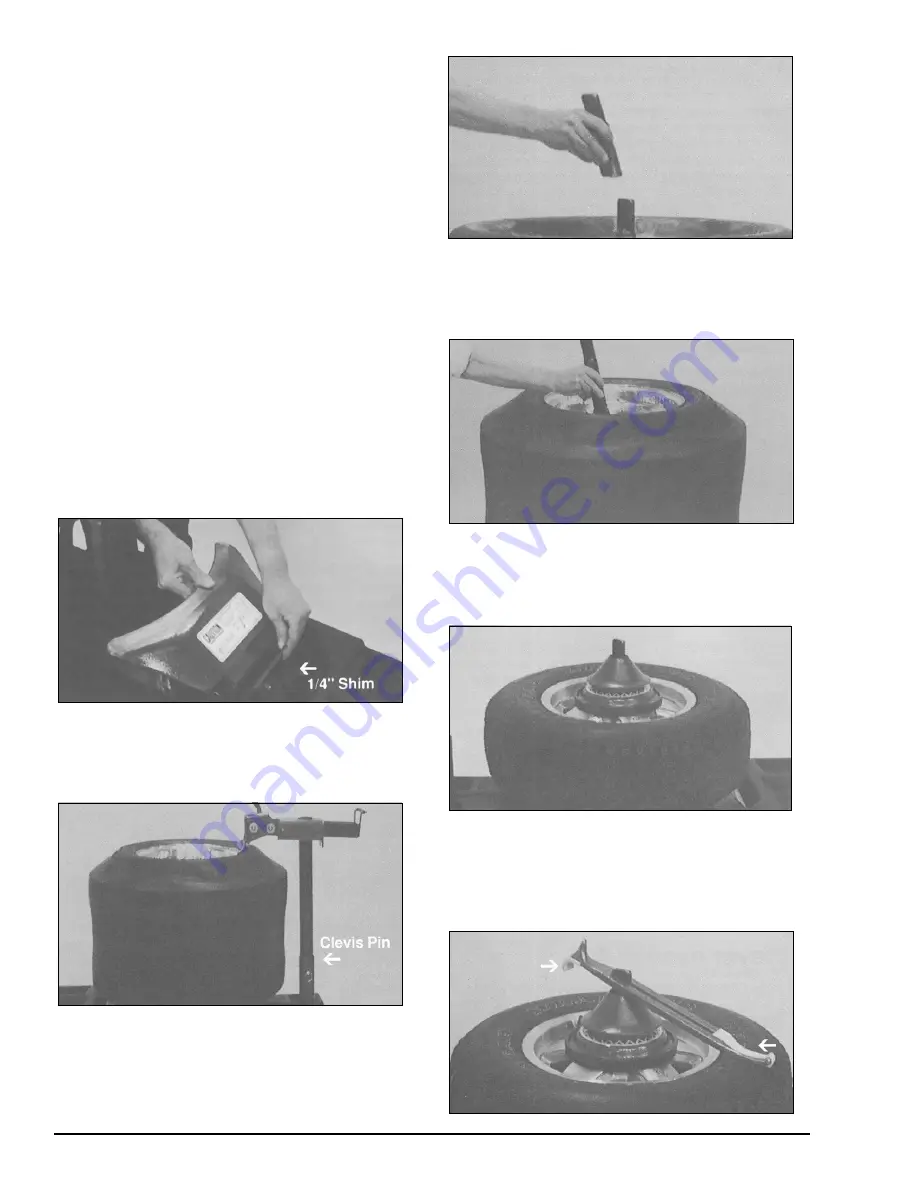

To service wheels over 11” wide, extend the

upper bead loosener post. Remove the clevis

pin, raise the post to the appropriate height,

and reinsert the pin (figure 18).

Figure 18- Extending Upper Bead Loosener Post

3.

For mounting and demounting tires on wheels

from 10” to 14” wide, use the optional short

center post extension (part #8108311). Slip the

extension over the center post key (figure 19).

Figure 19- Optional Short Center Post Extension

4.

For mounting and demounting tires on wheels

wider than 14”, use the optional center post

extension (part #8108313). Slip the extension

over the center post key (figure 20).

Figure 20 - Optional Long Center Post Extension

5.

On wheels with thin or delicate center holes

that may be damaged by the centering cone,

use the optional Speed Mag or Custom

Wheeler Adapter (figure 21).

Figure 21 - Optional Speed Mag Adapter

6.

Use the platic combination tool boots supplied

with the optional Speed Mag adapter to

prevent scratching of custom wheels (figure

22). Boots may be ordered separately (part

#8106568, 10 pairs).

Figure 22 - Combination Tool Boots

8 • COATS 4050A Tire Changer