Custom and Special Wheels

Alloy Wheels

Some manufacturers offer wheels with little or no

drop center. These are not DOT approved. The tire

or wheel - or both - can be damaged and the tire

could explode under pressure, resulting in serious

in jury or death. If you attempt to mount/demount

this type of wheel, use extreme caution.

Figure 23 - No Drop Center

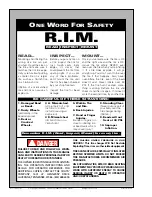

European Performance Wheels

(Asymmetrical Hump)

Some European wheels have very large humps

except near the valve hole. On these wheel, the

beads should be loosened at the valve hole on

both the upper and lower sides first.

Figure 24 - Asymmetrical Hump on European Wheels

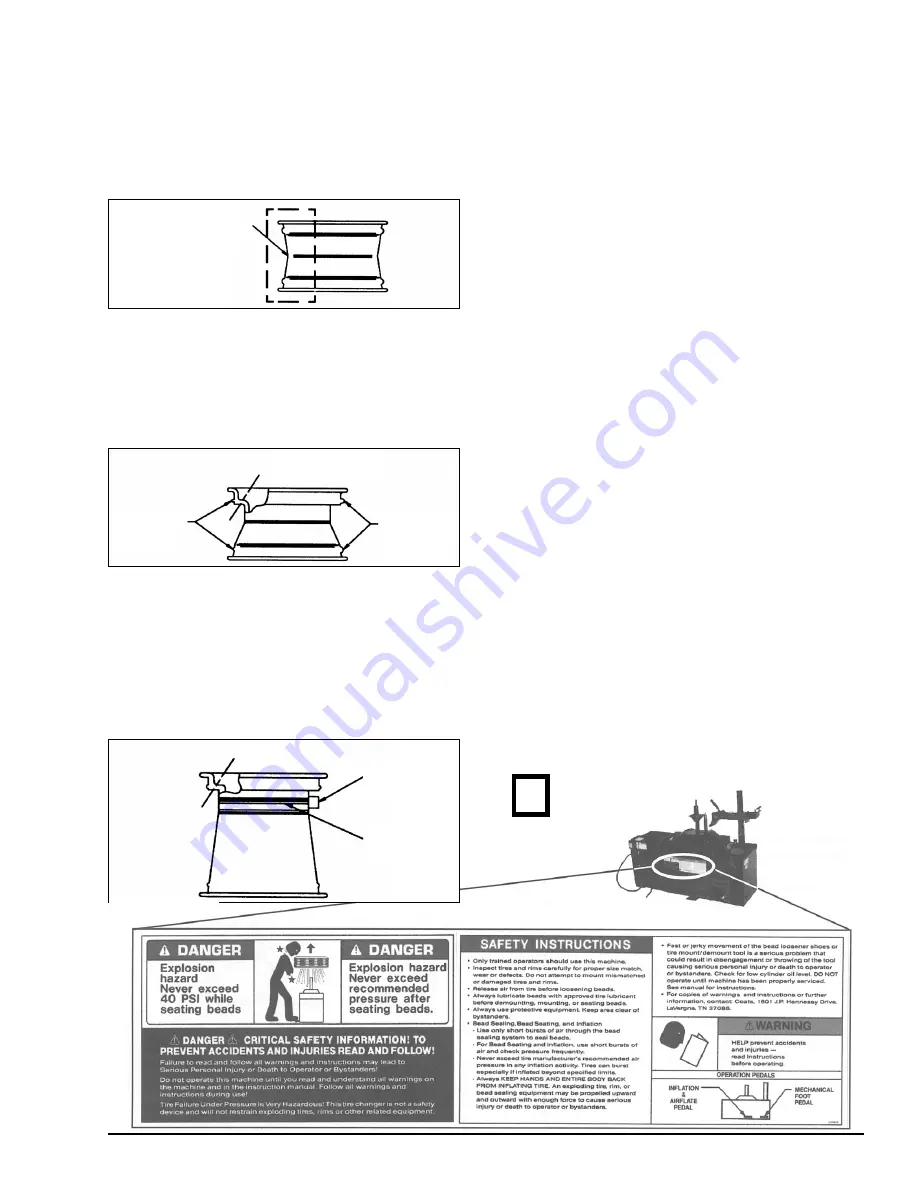

Wheels with Low Pressure Warning System

Sensors

Performance wheels on some vehicles (including

Corvette, BMW, Lamborghini Diablo) have a

pressure sensor strapped to the rim opposite the

valve hole. On these wheels, the beads should be

loosened at the valve hole on both upper and

lower sides first.

Figure 25 - Wheels with Low Pressure Sensor

Tube-Type Tires

Mounting

1.

Avoid pinching or forcing the tube.

2.

Apply rubber lubricant to the beads of the tire.

3.

Mount the bottom bead.

4.

Put a small amount of air into the tube to

round it out.

5.

Apply rubber lubricant to the tube and the

mounting end of the combination tool.

6.

Insert the tube into the tire.

7.

Mount the top bead.

Demounting

1.

After tire beads are loosened, lubricate the

beads and rim liberally.

2.

Position the combination tool as described in

step 8 on page 4.

3.

Rotate the center post key/combination tool in

short steps. Depress the foot pedal and release

if after a short amount of travel. This allows

you to stop the process should the tube get

pinched.

4.

During the demount operation, allow the

combination tool to rotate only from the

starting position at 5 o’clock to the 11 o’clock

position. This will keep the tool from

contacting the lower bead loosener as it moves

upward each time the machine is cycled.

5.

After the upper bead is demounted, remove

the tube from the tire and demount the lower

bead.

Do it Now

Always check to be sure you 4050 has a clearly

visible operator instruction decal.

COATS 4050A Tire Changer • 9

✓

No Drop Center

Slight

Hump

Large

Hump

Valve Hole

Transmitter

Mounting

Strap

Valve Hole