COATS 4050A Tire Changer • 11

Maintenance Instructions

Read and follow all the maintenance instructions

provided in this manual to keep the machine in

good operating condition. Refer to the other

materials received with the unit and to the service

bulletins from the manufacturer for additional

instructions on proper maintenance and service.

Regular inspections and proper maintenance are

essential to preventing accidents and injuries.

Before making any

i n s p e c t i o n ,

adjustment, or repair,

disconnect the power source and block out all

moving parts to prevent injury.

Keep the machine and

the immediate work

are clean. Do not use

compressed air to remove dirt and debris from the

machine. Foreign material may be propelled into

the air and into operator or bystander causing

personal injury.

Wear protective

clothing and use eye

protection when

making any adjustments or repairs to the

machine.

Cylinder Maintenance

The unique design of the hydraulically dampened

7” cylinder controls bead loosening, mounting,

and demounting. Internal sealing surfaces are

chrome plated to provide long seal life. A small

amount of oil is ususally lost after a period of time

in lubricating the seals. It is important that the

cylinder be filled to the proper level at all times. If

the oil becomes low, the machine will surge at the

beginning of its stroke. Cylinder oil level should be

checked before initial operation and weekly

thereafter. A special hydraulic oil must be used.

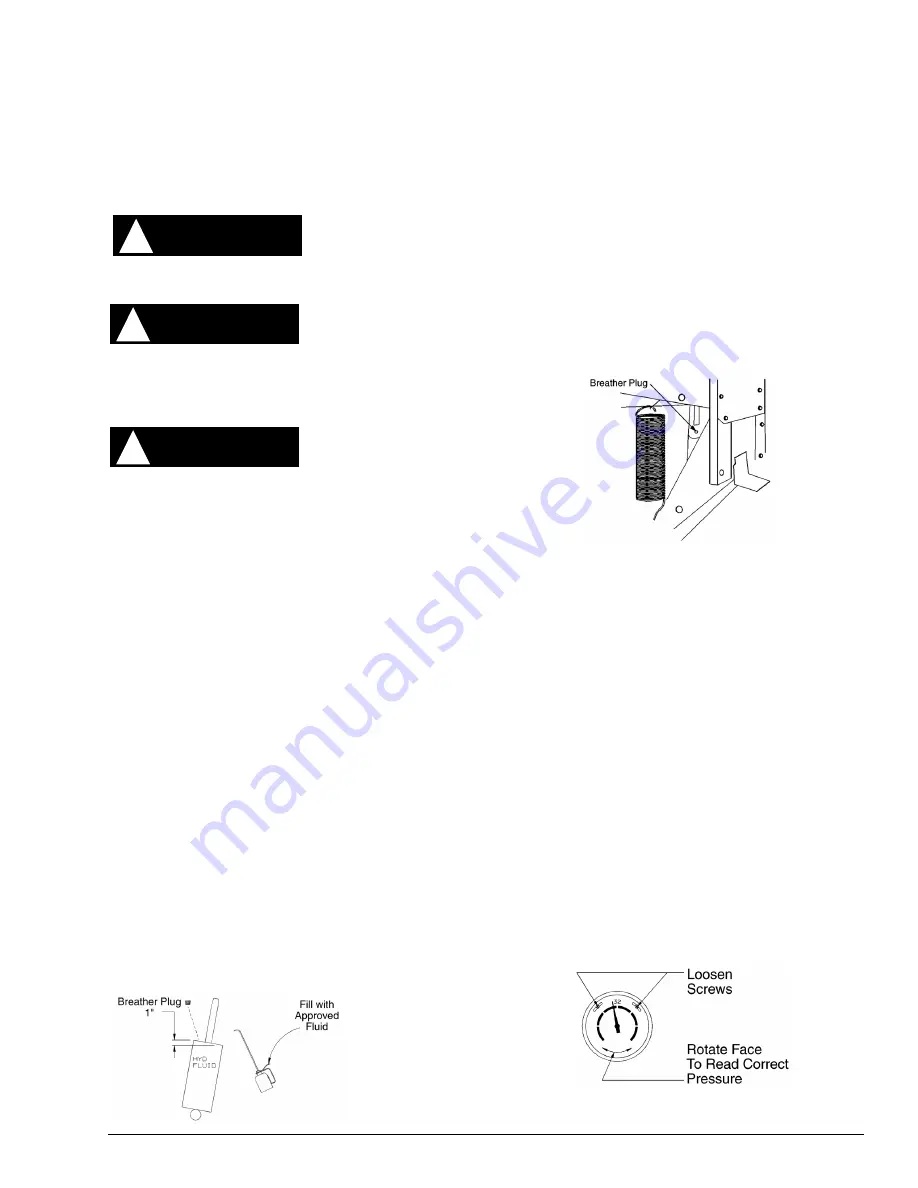

Filling 7” Cylinders

Fill only with COATS Hydraulic Oil (part #8101411)

or an approved alternate choice (Empak 4061, or

Shell Tellus 21). Do not use motor oil or brake

fluid.

1.

Remove the front panel by removing 4 self

tapping bolts and 3 self tapping screws.

2.

Depress and hold the foot pedal to extend the

cylinder to the top of its stroke.

3.

Remove the plastic breather plug. Fill the

cylinder to within 1” to 1-3/16” of the access

hole in the top. Be careful no dirt falls in

through the hole (figure 26).

4. Reinstall breather plug and reattach front panel.

Figure 26 - Filling

the 7” Cylinder

5” Cylinders

The 5” cylinder requires periodic lubrication. This

can be performed without removing the cylinder

from the unit.

1.

Remove the side panel on the foot pedal side

of the unit by removing 4 hex bolts and 3 hex

screws.

2.

Depress and hold the foot pedal to extend the

cylinder to the top of its stroke.

3.

Remove the white breather plug on the cylinder

and add 1/2 ounce of 10W-30 motor oil with a

funnel or long spout oil can (figure 27).

IMPORTANT: Do not fill the 5” cylinder with oil.

4.

Reinstall the breather plug and reattach the

side panel.

Figure 27 - Lubricating the 5” Cylinder

Pressure Gauge Maintenance and Calibration

Check the tire pressure gauge function on the unit

daily, and perform an accuracy check monthly. Use

a pressurized tire and a high quality stick pressure

gauge. If necessary, calibrate the dial of the

machine gauge.

1.

Pressurize a large 15” tire to 30PSI and

measure the pressure exactly with a high

quality extension type tire gauge. Connect the

air chuck to the tire.

2.

Remove the gauge lens and loosen the 2

screws at the top of the gauge and rotate the

gauge face until the indicator is pointed at the

correct pressure as read with the extension

type tire gauge (figure 28).

3.

Tighten gauge face screws and replace lens.

If gauge is defective, replace it immediately (part

#8107980).

Check the function of the pressure limiter weekly

as part of your pressure gauge maintenance and

calibration.

igure 28 - Calibrating Pressure Gauge

WARNING

!

WARNING

!

CAUTION

!