12 • COATS 4050A Tire Changer

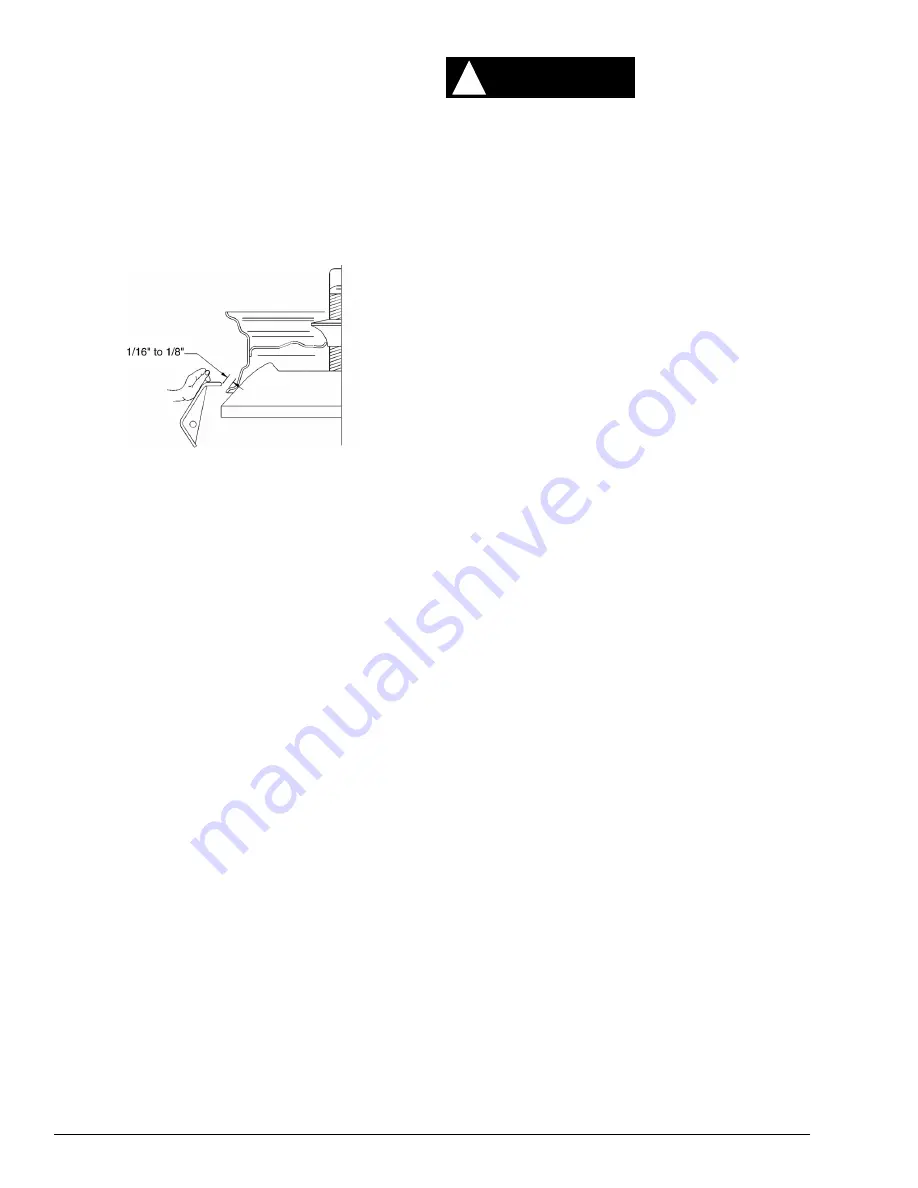

Lower Shoe Setting

Check the lower shoe setting periodically to make

sure that it operates properly and does not contact

the wheels.

1.

Place a 15” steel wheel on the machine and

secure with the centering cone.

NOTE: Make sure the wheel is centered.

2.

Depress the foot pedal and run the lower shoe

up to 45 degrees above the radius of the lower

rim flange. Refer to figure 29.

3.

Use your left hand to push against the shoe as

forcefully as possible.

4.

Measure the gap between the closest point of

the shoe and the rim flange. The ideal

measurement is between 1/16” and 1/8”.

• If the shoe contacts the rim, add another shim.

• If the gap is smaller than 1/16”, add another shim.

• If the gap is larger than 1/8”, remove one shim.

IMPORTANT: A high setting (greater than 1/8”) is

more desirable than a low setting (less than 1/16”).

If additional shims are required, a Shim Kit (part

#8101506) is available.

Routine Maintenance

A. Keep work surface clean. Pay special attention

to the top of the machine.

B. Clean and wipe down the machine on a regular

basis.

C. Clean the gauge lens frequently with glass

cleaner.

D. Make sure all fasteners are tightened securely.

E. Make certain that all guards and covers are in

place.

F.

Check for worn, damaged, or missing parts

(including grips, warnings, instructions, and

protective covers). Replace before allowing unit to

be used.

G. Inspect the unit on a daily basis. Check that all

systems and functions are operating normally.

Detailed inspection and testing procedures are

specified for various components at regular

intervals. Set up a chart and assign responsibility

for these items.

These instructions will

help you service the unit.

Instructions are for a

person with some mechanical ability and training.

No attempt has been made to describe all basic

steps. For example, how to loosen or tighten

fasteners. Also, basic procedures such as how to

cycle systems and check operation of the

equipment are not fully described since they are

known to anyone who does mechanical and service

work. Do not attempt to perform work beyound

your ability, or at which you have no experience.

If you need assistance or technical support, contact

an authorized COATS Service Center, or The

COATS Company Service Department at (800) 688-

6359.

CAUTION

!