8111144 02/97

© Copyright 1993, 2001 Hennessy Industries and COATS

®

All Rights Reserved

Printed in USA

FAILURE TO READ AND FOLLOW ALL WARN-

INGS AND INSTRUCTIONS IN THIS MANUAL

CAN LEAD TO SERIOUS PERSONAL INJURY OR

DEATH TO OPERATOR OR BYSTANDER.

THE OWNER IS RESPONSIBLE FOR MAINTAIN-

ING THE OPERATION INSTRUCTIONS AND

DECALS FOR OPERATOR REFERENCE. FOR

ADDITIONAL COPIES, CONTACT THE COATS

®

COMPANY, 1601 J.P. HENNESSY DRIVE,

LAVERGNE, TENNESSEE, 37086 - (800) 688-6359.

TIRE FAILURE UNDER PRESSURE IS HAZ-

ARDOUS! This tire changer Will Not Restrain

Exploding Tires, rims or other related equipment.

TIRES CAN EXPLODE, ESPECIALLY IF INFLATED

BEYOND SPECIFIED LIMITS. DO NOT EXCEED

TIRE MANUFACTURERS RECOMMENDED AIR

PRESSURE.

AN EXPLODING TIRE, RIM, OR BEAD SEATING

EQUIPMENT MAY PROPEL UPWARD AND OUT-

WARD WITH SUFFICIENT ENERGY TO CAUSE

SERIOUS INJURY OR DEATH TO OPERATOR

AND/OR BYSTANDERS.

DANGER

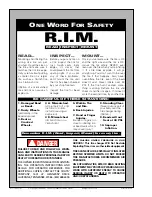

READ…

Mounting and inflating the

wrong size tire can get

you hurt.

Read the size on

the tire and make sure it

matches the rim. Be espe-

cially careful about putting

a smaller tire on a larger

rim, such as a 16-inch tire

on a 16.5-inch rim.

Inflation of a mismatched

tire and rim can cause an

explosion.

INSPECT…

Before you put any tire on

a rim,

inspect the rim for

rust, tough spots, bent

edges, or cracks that

could prevent the tire from

seating right. If you spot

any of these problems,

don’t mount the tire until

the rim has been checked

by your shop foreman.

Inspect the tire for bead

damage.

MOUNT…

Once you’ve made sure the tire is OK

and the right size and the rim is OK,

mount the tire safely. NEVER, ever

lean over the tire when you’re inflating

it. If a tire does explode, it will go

straight up. You don’t want to be over

the tire if that happens. Also, never

over-inflate the tire, even if the bead

doesn’t seat. Never inflate over 40

PSI. If the tire hasn’t seated, some-

thing is wrong. Deflate the tire and

check it and the rim again. If it doesn’t

work the second time, try another tire.

1. Damaged Bead

or Beads.

2. Rusty Wheels.

(particularly in the

bead seat area)

3. Bent or

Cracked

Wheels.

4 A. Mismatched.

(A mis-match of a 16-

inch tire to a 16.5-

inch rim causing an

explosion)

4 B. Mismatched.

(16.5-inch tire on a

16-inch rim)

5. Walk-In Tire

and Rim.

6. Back Injuries.

7. Hand or Finger

Injuries.

(Hands or fingers too

close to inflating tire

or bead seats which

may cause injury.)

8. Standing Clear.

(Never put any part of

your body over the

tire changer during

inflation.)

9. Beads will not

Seat at 40 PSI.

10. Improper

Inflation.

Remember R.I.M.

(Read, Inspect, Mount)

for every tire.

BE CAREFUL OF THESE SITUATIONS:

O

NE

W

ORD

F

OR

S

AFETY

R.I.M.

READ INSPECT MOUNT