Table of Contents

Definitions of Hazard Levels ................................1

Owner's Responsibility ........................................1

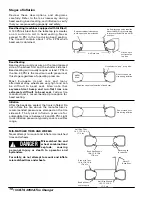

Principal Operating Parts .....................................2

Operating Instructions .........................................3

Bead Loosening and Demounting ................3

Mounting .........................................................5

Inflation ..................................................................6

Bead Sealing ...................................................6

Bead Seating ...................................................6

Inflation ...........................................................7

Performance Tires/Custom Wheels ....................8

Custom and Special Wheels ................................9

Tube Type Tires ...................................................12

Stages of Inflation ...............................................10

Bead Seal ......................................................10

Bead Seat ......................................................10

Inflation .........................................................10

Mis-Matched Tires and Wheels .........................10

Maintenance Instructions ..................................11

Installation Instructions .....................................13

Critical Safety Instructions .................Back Cover

Operator Protective Equipment

Personal protective equipment helps make tire

changing safer. However, equipment does not

take the place of safe operating practices.

Always wear durable work clothing during tire

service activity. Shop aprons or shop coats may

also be worn, however loose fitting clothing

should be avoided. Tight fitting leather gloves

are recommended to protect operator’s hands

when handling worn tires and wheels. Sturdy

leather work shoes with steel toes and oil

resistant soles should be used by tire service

personnel to help prevent injury in typical shop

activities. Eye protection is essential during tire

service activity. Safety glasses with side shields,

goggles, or face shields are acceptable. Back

belts provide support during lifting activities

and are also helpful in providing operator

protection. Consideration should also be given

to the use of hearing protection if tire service

activity is performed in an enclosed area, or if

noise levels are high.

For additonal tire, wheel, and/or inflation

information contact the following:

RUBBER MANUFACTURERS ASSOCIATION

1400 K Street N.W.

Washington, DC 20005

(202) 682-4800

www.rma.com

TIRE GUIDES, INC.

The Tire Information Center

1101-6 South Rogers Circle

Boca Raton, FL 33487-2795

(561) 997-9229

www.tireguides.com

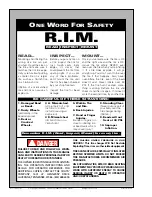

Failure to follow danger,

warning, and caution

instructions may lead to

serious personal injury or

death to operator or bystander or damage to

property. Do not operate this machine until you

read and understand all the dangers, warnings

and cautions in this manual. Download a copy of

the manual from our website at

www.ammcoats.com, or for further information,

contact:

Hennessy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086-3565

(615) 641-7533 or (800) 688-6359

www.ammcoats.com

WARNING