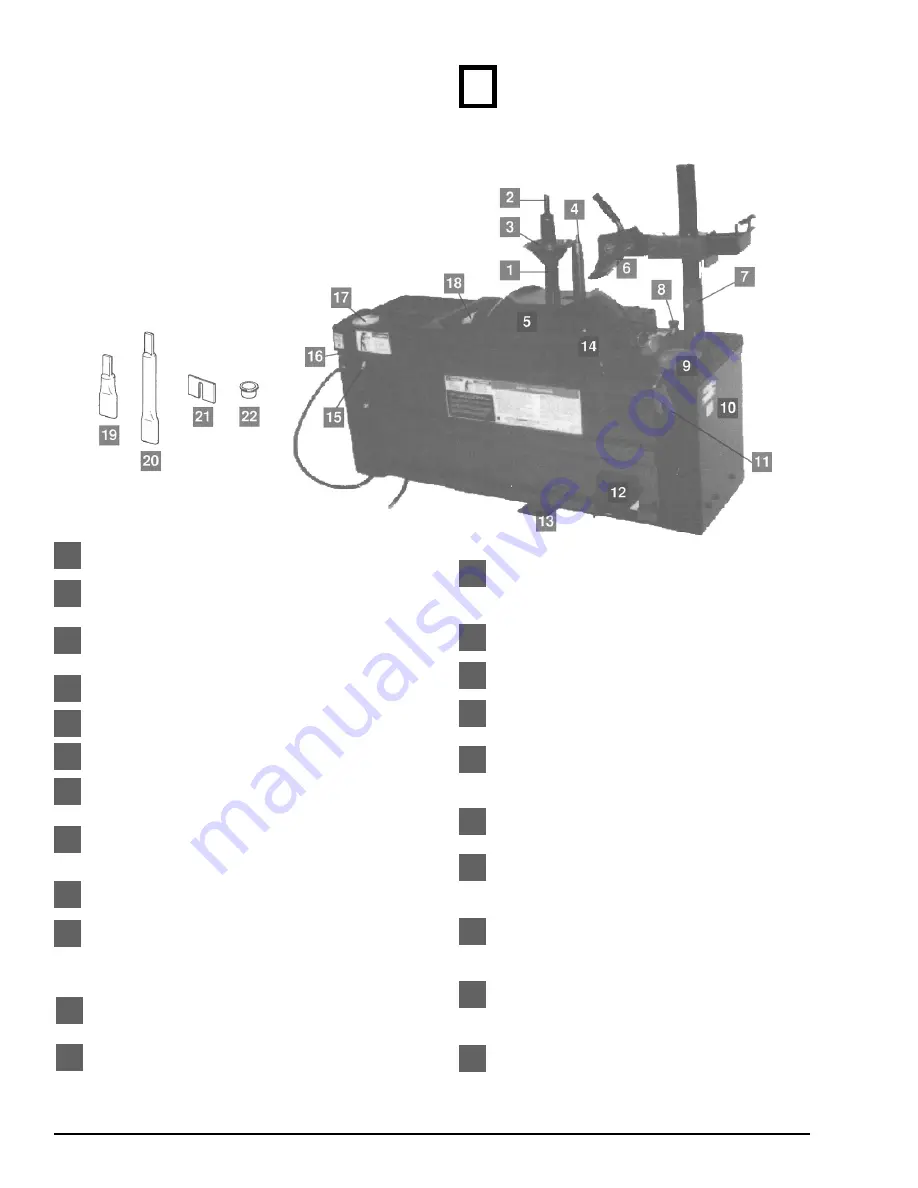

Principal Operating Parts

Know Your Unit

Compare this illustration with the unit before

placing it into service. Maximum performance

and safety will be obtained only when all

persons using the unit are fully trained in its

parts and operation. Each user should learn the

function and location of all controls. Prevent

accidents and injuries by ensuring the unit is

properly installed, operated, and maintained.

Center Post

Center Post Key —

Rotates combination tool for

mounting and demounting operations.

Centering Cone —

Centers the wheel to the

contoured table top.

Positioning Pin —

Engages lug hole in wheel to

prevent rotation during mounting and demounting.

Contoured Table Top

Upper Bead Loosener Shoe

Adjustable Upper Bead Loosener —

Adjusts to

accomodate wide wheels.

Detent Control Knob —

Controls the amount of travel

of the lower bead loosener to prevent damage to

large diameter narrow wheels and reverse mount wheels.

Rubber Lubricant Dispenser

Serial Number Plate —

Record the serial number on

the Owner’s Registry Card and on your copy of the

warranty card. Provide this number with any warranty or

service claim, and with all parts orders.

Combination Tool —

Used in mounting and

demounting operations.

Foot Pedal —

Operates the air valve for power bead

loosening, mounting, and demounting.

Do It Now

Now is a good time to fill out the warranty

registration card. This card must be mailed

within 30 days of purchase or the warranty

may be voided.

Air-Flate Pedal —

3 position pedal for tire inflation

via air hose/chuck. Do not press without tire/wheel

assembly on unit.

Air-Flate Jets —

Expands tire sidewalls to bead seat

portion of rim for the bead sealing process.

Air Chuck —

Clip-on style.

Manual Release Valve —

Allows for manual release

of air pressure from the tire.

Air Gauge —

Registers tire pressure when air chuck

is attached to the valve stem and inflation pedal is

released.

Lower Bead Loosener —

2 shoes for lower bead

loosening.

Short Center Post Extension (Optional, Part

#8108313) —

Lengtens center post for wheels

between 10 an 14 inches wide.

Long Center Post Extension (Optional, Part

#8108313)

—

Lengtens center post for wheels over

14 inches wide.

1/4” Shim —

Installs on lower bead loosener to

prevent damaging aluminum and magnesium wheels

with wide flanges.

Hold Down Tube —

Used with styled steel wheels to

prevent the centering cone from touching the wheel.

2 • COATS 4050A Tire Changer

1

2

8

7

6

5

4

3

✓

9

10

11

12

13

14

15

16

17

18

19

20

21

22