Operating Instructions

The unit must be properly operated and properly

maintained to help avoid accidents that could

damage the unit and injure the operator or

bystanders. This section of the Operating

Instructions manual review basic operations and

use of controls. These instructions should be

reviewed with all employees before they are

allowed to work with the machine. Keep these

instructions near the machine for easy reference.

Bead Loosening and Demounting

This machine may

operate differently

from machines you

have previously operated. Practice with a regular

steel wheel and tire combination to familiarize

yourself with the machine's operation and

function.

NOTE: Always review nicks and scratches with

owners of expensive wheel and tire combinations

prior to servicing.

IMPORTANT: Refer to the Performance Wheels

and Tires section of this manual before servicing

custom and performance wheel and tire

combinations.

IMPORTANT: Refer to the Tube Type Tires section

of this manual before servicing tires with tubes.

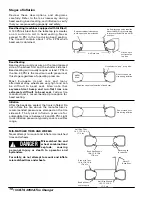

1.

Determine the correct side of the wheel for tire

removal. Remove the tire from the narrow side

(tire mounting side). Tire will not mount or

demount from the long side.

NOTE: On some wheels, the sides may be nearly

equal. Measure carefully. Only the narrow side is

used for mounting and demounting.

Figure 1 - Determining Tire Mounting Side

2.

Remove the valve core and allow all of the air

to escape from the tire. Remove all weights

from rim.

3.

Place the tire/wheel assembly over the center

post and down onto the contoured table top,

with the narrow side of bead seatup (figure 1).

The positioning pin must engage a lug hole in

the wheel. Position the tire/wheel assembly so

that the valve stem is on the operator’s side of

the machine.

NOTE: Make fine adjustments to the lower

bead loosener shoe with the shim kit before

placing mag or alloy wheel assemblies on the

table top. Refer to the instructions on bead

loosener shoe and pages 8 and 12.

4.

Thread centering cone clockwise onto the

center post. As the tapered end enters the

center hole of the wheel, the tire/wheel

assembly will adjust itself on the table top. Be

sure the cone is hand tight and is centered in

the wheel’s center hole (Fig. 2).

Figure 2 - Thread the Centering Cone onto the Center Post

5.

Check the detent control knob for proper

setting. Forward is used for all tire and wheel

combinations except 15”x4”, 16”x5” to 7”, and

17.5”x5.5” to 7.5”. To move the detent lever,

push the knob down, move it to the proper

setting, and release the knob (fig.3).

Figure 3 - Positioning the Detent Control Knob

6.

Place the upper bead loosener shoe on the tire

next to, but not on, the rim (fig.4). Press down

on the foot pedal until both bead looseners

complete their full stroke. If the top bead is not

completely loosened, release the foot pedal

until the unit has completed the full return

stroke and press the foot pedal again. The

ratchet effect on the loosener will deliver a

deeper stroke. The repeat cycle is used only if

the upper bead is not loosened.

Figure 4 - Positioning the Upper Bead Loosener Shoe

Note: If may be necessary to loosen the bead at

different points around the wheel circumference to

entirely free the bead.

COATS 4050A Tire Changer • 3

CAUTION

!

Narrow Side

Long Side

Drop Center