7.

Once the tire beads have been loosened from

the bead seat of the wheel, lubricate the beads

liberally with rubber lubricant (fig.5).

Note: Rubber lubricant makes demounting

easier, helps eliminate damage to the tire

beads, and assists the movement of the

combination tool.

Figure 5 - Lubricate Tire Beads

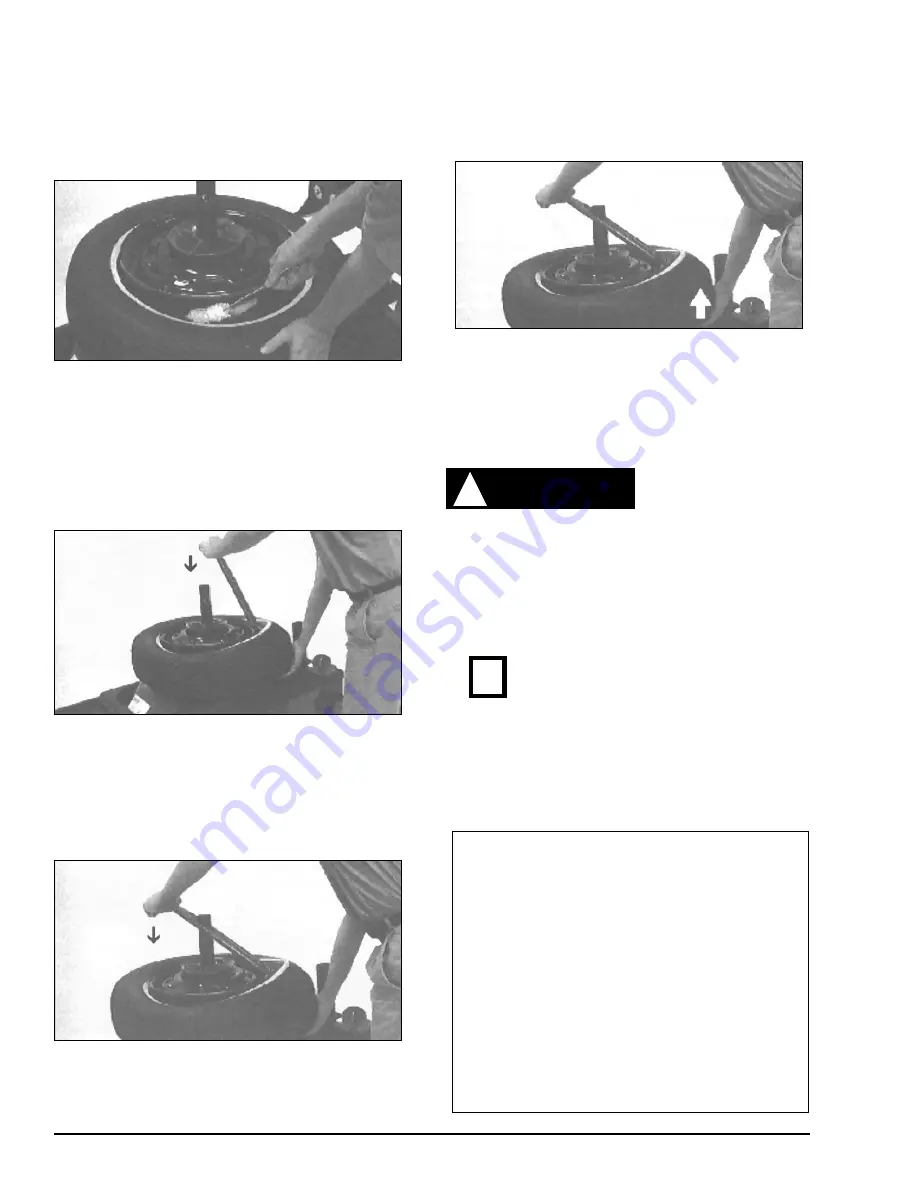

8.

Position the combination tool so that it aligns

with the center post key. Insert the demount

end of the tool between the tire and rim. Push

the tool down towards the center post as

shown in figure 6 to lift the tire bead over the

rim.

IMPORTANT: Make sure the tool is oriented as

shown in figure 6.

Figure 6 - Align, Insert, and Push Down on the Tool

9.

Continue to push down on the tool until the

center post key protrudes through the slot in

the tool and the tool stops against the shoulder

of the key. The tool is now positioned properly

for operation of the center post key (figure 7).

Keep a firm hold on the tool at all times to

prevent accidental disconnet.

Figure 7 - Tool Properly Positioned

10. Press down on the foot pedal. The

counterclockwise rotation of the center post

key and combination tool will remove the

upper tire bead from the rim. Lifting up on the

tire with the left hand as shown by the arrow in

figure 8 helps in demounting tougher tires.

Figure 8 - Removing Upper Bead

10. To remove the lower bead from the wheel,

repeat steps 8, 9, and 10.

REMEMBER: Refer to the Tube Type Tire

section of this manual before servicing tires

with tubes.

Fast or jerky

movement of the bead

loosener shoes or the

combination tool indicates low cylinder oil level,

and may result in throwing or disengaging of the

tool, possibly causing serious injury or death to

operator or bystander. Do not operate until it has

been returned to proper operating condition. See

the Maintenance section of this manual for further

instructions on maintenance and adjustment.

When the demount operation is

complete, proceed with Mounting,

page 5.

4 • COATS 4050A Tire Changer

Operator Protective Equipment

Always wear durable work clothing during tire

service activity. Shop aprons or shop coats may

also be worn, however, loose fitting clothing

should be avoided. Tight fitting leather gloves

are recommended to protect the operator's

hands when handling worn tires and wheels.

Sturdy leather work shoes with steel toes and

oil resistant soles should be used by tire service

personnel to help prevent injury in typical shop

activities. Eye protection is essential during tire

service activity. Safety glasses with side shields,

goggles, or face shields are acceptable. Back

belts provide support during lifting activities

and are also helpful in providing operator

protection.

DANGER

!

✓