Inflation

Tire inflation is performed in three steps: Bead

Seal, Bead Seat and Inflation. These steps are

explained in detail on page 10. Read the

explanation of each step and understand them

thoroughly before proceeding.

Check for proper

inflation gauge

operation. Accurate

pressure readings are important to safe tire

inflation. Refer to the Operating Maintenance

section of this manual for instructions.

Tire failure under

pressure is hazardous.

This tire changer is not

intended to be a safety device to contain

exploding tires, tubes, wheels, or bead sealing

equipment. Inspect tire and wheel carefully for

match, wear, or defects before mounting. Always

use approved tire bead lubricant during mounting

and inflation.

Figure 13 - Air-Flate Pedal Positions

The COATS Air-Flate system is operated with a

three position foot pedal (referred to as the Air-

Flate pedal). Each position of the Air-Flate pedal

performs a specific function (figure 13):

Position 1 - Tire Pressure –

When foot is removed

from the pedal, it will return to this position. When

the inflation hose is attached to the tire valve, the

pressure gauge will register the pressure in the

tire.

NOTE: The clip-on chuck on the end of the hose is

an important safety aid and should always be an

open style with all parts in proper working order.

Position 2 - Tire Inflation –

By pressing the Air-

Flate pedal down to this first activated position, full

air line air pressure is applied to the inflation hose

for tire inflation. Remove your foot from the pedal

(position 1) to read tire pressure on the pressure

gauge. See page 7 for pressure limiter information.

Position 3 - Bead Sealing –

Press the pedal down

fully and full air line air pressure is applied to the

inflation hose and to the bead seal jets mounted in

the top cover.

Use Position 3 for bead

sealing only. Do not use

this position without a

tire and wheel positioned on the tabletop. Dirt and

debris could be blown into the air with enough

force to injure the operator or bystanders. Do not

use the position to inflate a tire.

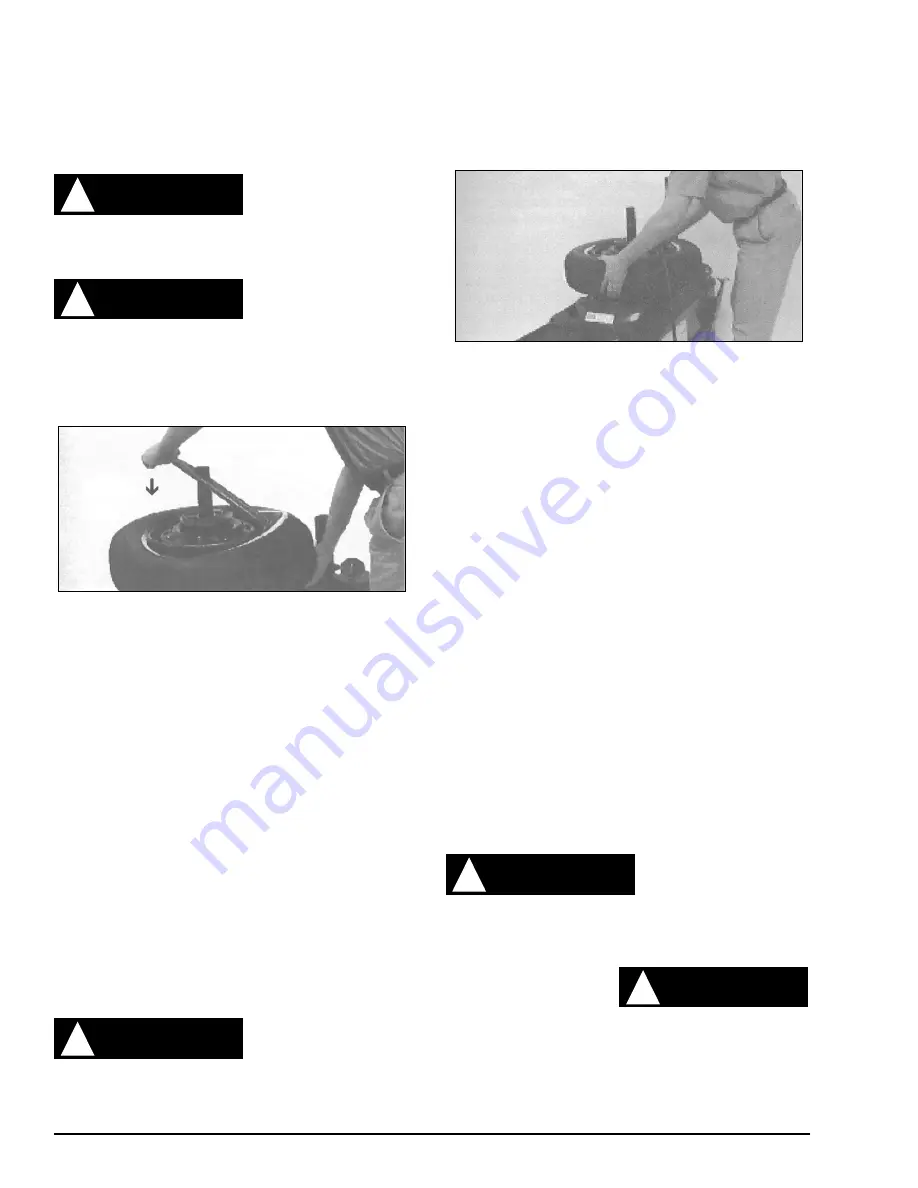

Bead Sealing

1.

Connect the inflation hose to the tire valve stem.

2.

Lift tire so that the upper bead is against the

edge of the rim to create a seal. Be sure the

upper bead is over the bottom of the valve

stem (figure 14).

Figure 14 - Bead Sealing

3.

Depress the Air-Flate pedal to position 2 and

hold for 1 second to begin air flow through the

inflation hose, then depress the Air-Flate pedal

fully to position 3, hold very briefly (less than 1

full second), and remove foot from the pedal.

The blast of air through the inflation hose and

the top cover jets will expand the tire and seal

the beads (figure 14).

4.

Check to make sure that the beads are sealed

to the wheel. Repeat step 3 if they are not fully

sealed.

NOTE: Allow time for the surge tank pressure

to recover before depressing the pedal to

position 3 again.

TIP: If the tire and wheel are properly lubricated and

the operator cannot achieve bead seal after 3

attempts, it may help to remove the valve core.

Remove the air chuck from the valve stem and

unscrew the valve core from the stem. Reattach the

air chuck and perform the bead seal operation again.

5.

Check tire pressure (Air-Flate pedal must be in

position 1). If pressure is indicated in tire, bead

seal has been obtained. Proceed to Bead

Seating.

Bead Seating

Operator should keep

hands, arms, and

entire body away from

the tire and wheel during the remaining Bead Seat

and Inflation procedures. Do not stand over tire,

as personal injury could result.

NEVER increase air

pressure to exceed 40

PSI when attempting

Bead Seat. If unable to obtain Bead Seat,

something is wrong. Deflate tire completely,

inspect both the tire and wheel, and correct any

problems found. Relubricate both tire beads, and

reattempt Bead Seal and Bead Seat procedures.

Follow all safety instructions in this manual and

on machine.

6 • COATS 4050A Tire Changer

CAUTION

!

DANGER

!

CAUTION

!

WARNING

!

WARNING

!