Check tire pressure

frequently. Never

exceed 40 PSI while

seating beads. Once seated, never exceed tire

manufacturer's recommended air pressure. Tires

can explode, especially if they are inflated beyond

their limits. At all pressure levels when inflating

through the valve stem, keep hands, arms, and

entire body away from inflating tire. An exploding

tire, wheel, or bead sealing equipment may propel

upward and outward with sufficient force to cause

serious injury or death to operator or bystander.

1.

Verfy that beads are sealed by checking the

gauge for air pressure int the tire. Do not

proceed if beads are not sealed.

2.

If beads are sealed, loosen the centering cone

one full turn. DO NOT REMOVE IT!

3.

Inject frequent, short bursts of air into the tire

by pressing the Air-Flate pedal to position 2

and releasing. Continue the bursts until the

beads move outward into their bead seat

position. Check the pressure frequently. If

beads do not seat, a problem exists.

Investigate carefully and correct the problem.

Figure 15 - Stand Back During Beat Seat and Inflation

4.

Proceed to the inflation step only when both

beads are completely and properly seated.

Inflation

NEVER exceed tire

m a n u f a c t u r e r ' s

recommended air

pressure. Tires can explode, especially if inflated

beyond these limits. Keep hands, arms, and entire

body back from inflating tire. Avoid distraction

during inflation and observe tire pressure

frequently to avoid over inflation. Excessive

pressure can cause tires to explode, causing

serious injury or death to operator or bystander.

REMEMBER: If you removed the valve core for

bead sealing, it must be reinstalled before the tire

is inflated.

1.

Depress the Air-Flate pedal to position 2 and

inflate the tire. Release the pedal to position 1

and check the increasing pressure frequently to

avoid over inflation.

IMPORTANT: The 4050A is equipped with a

pressure limiter to assist the operator with proper

tire inflation. The 4050 limiter will keep most car

and light truck tires from inflating beyond 60 PSI

(smaller tires may reach higher pressures). Tires

that require inflation above 60 PSI should be

removed from the 4050 and inflated using a safey

chamber or safety cage. Tires can be over inflated

and explode even with the use of this pressure

limiter if other instructions in this manaul and on

the unit are not followed. Check the function of the

pressure limiter regularly and maintain as required

for safe and proper operation.

IMPORTANT INFLATION FEATURE: If the Air-Flate

pedal is held steady at position 2, the Air-Flate

system’s pressure limiter will automatically cycle

between inflation and off. This cycle will continue

until the pedal is released. The operator should

check the increasing pressure frequently to avoid

over inflation.

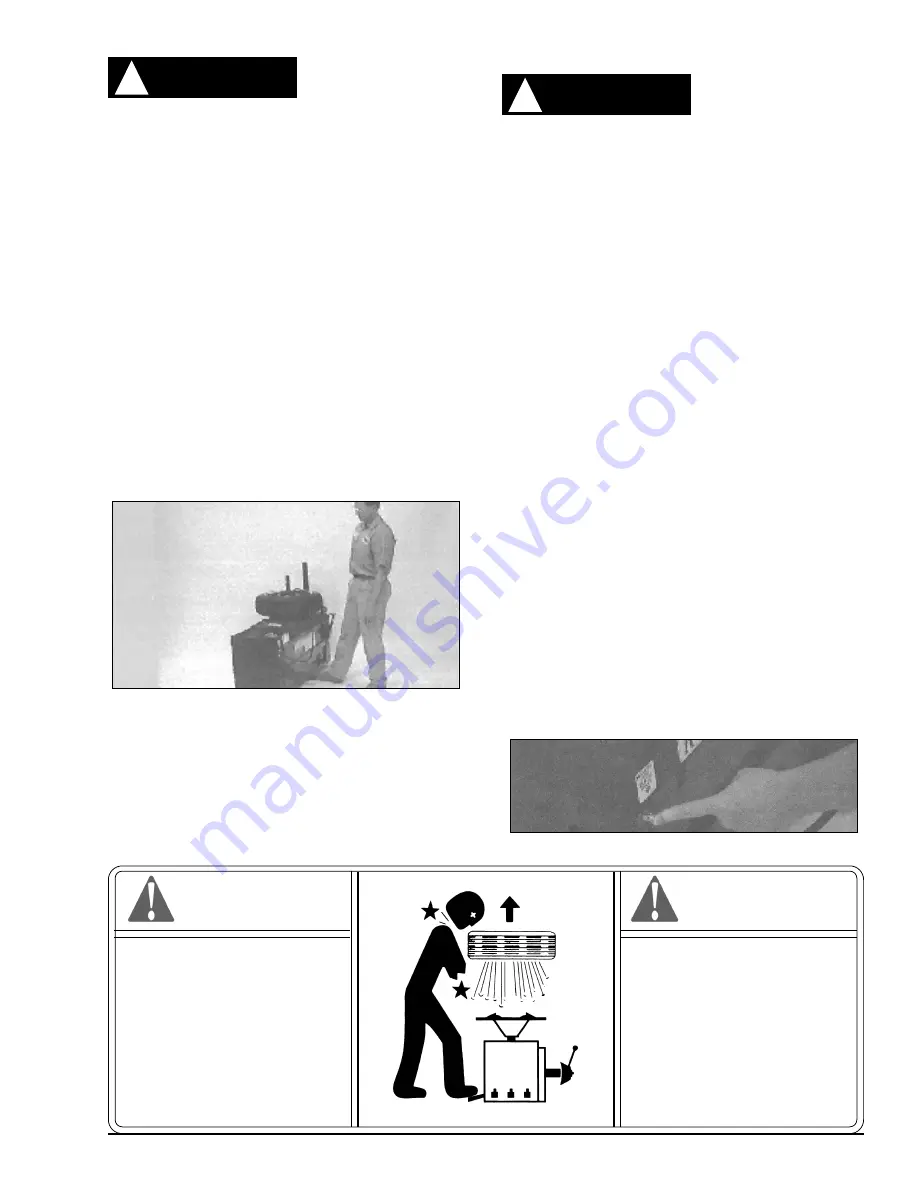

Figure 16 - Release Pressure with the Manual Release Valve

COATS 4050A Tire Changer • 7

WARNING

!

DANGER

!

Explosion Hazard

Never inflate

tire above

manufacturer's

recommended

pressure after bead is

seated.

DANGER

DANGER

Explosion Hazard

Never exceed 40 PSI

while seating beads.