Static Modes

Choose a static balance for wheel assemblies that

are not possible to balance dynamically or for narrow

wheels. For example, a motorcycle wheel that has a

small wheel width.

Select the MODE option

for the modes menu

and then select the STATIC MODES option

.

Choose the option that best fits the available weight

locations.

a. For a “single weight”, choose any one plane loca-

tion.

b. For “two weights”, choose any two plane locations.

Using this approach can reduce the amount of induced

dynamic unbalance by splitting the correctional weight

value among two different planes.

- STATIC1

- STATIC2

- STATIC3

- STATIC4

Have the following items handy: an appropriate wheel

assembly mounted on the balancer and a selection of

weights.

Special Modes

Select the MODE option

for the modes menu.

Select the SPECIAL MODES option

to choose a

mode for the following special type wheel assemblies.

PAX Balance -

Select the appropriate option for the

PAX wheel that best fits the available weight locations.

- PAX1

- PAX2

Have the following items handy: a PAX wheel assem-

bly mounted on the balancer and a selection of Tape-A-

Weights™.

Patch Weight Balance -

Use a static patch weight bal-

ance when there is a very large unbalance in a tire

assembly or if a very large tire has a large unbalance. A

weighted balance pad (patch weight) is placed inside the

tire in the center to compensate for the large unbalance.

- PATCH (static)

- DIAMETER

↑

Have the following items handy: measuring tape and

various patch weight sizes.

Note:

Before proceeding with Patch Weight Balance,

it is recommended that you use the Optimization

(Match Balance) procedure first, see page 21, in order

to use the smallest patch weight.

The Patch Weight Balance involves the loos-

ening of tire beads and the inflation of a tire.

Training is necessary in tire changer opera-

tion and understanding the dangers

involved during bead seating and tire infla-

tion before attempting this stage of the

Patch Weight Balance procedure. Read the

operators manual supplied with the tire

changer and consult a supervisor.

The patch weight balance steps are as follows:

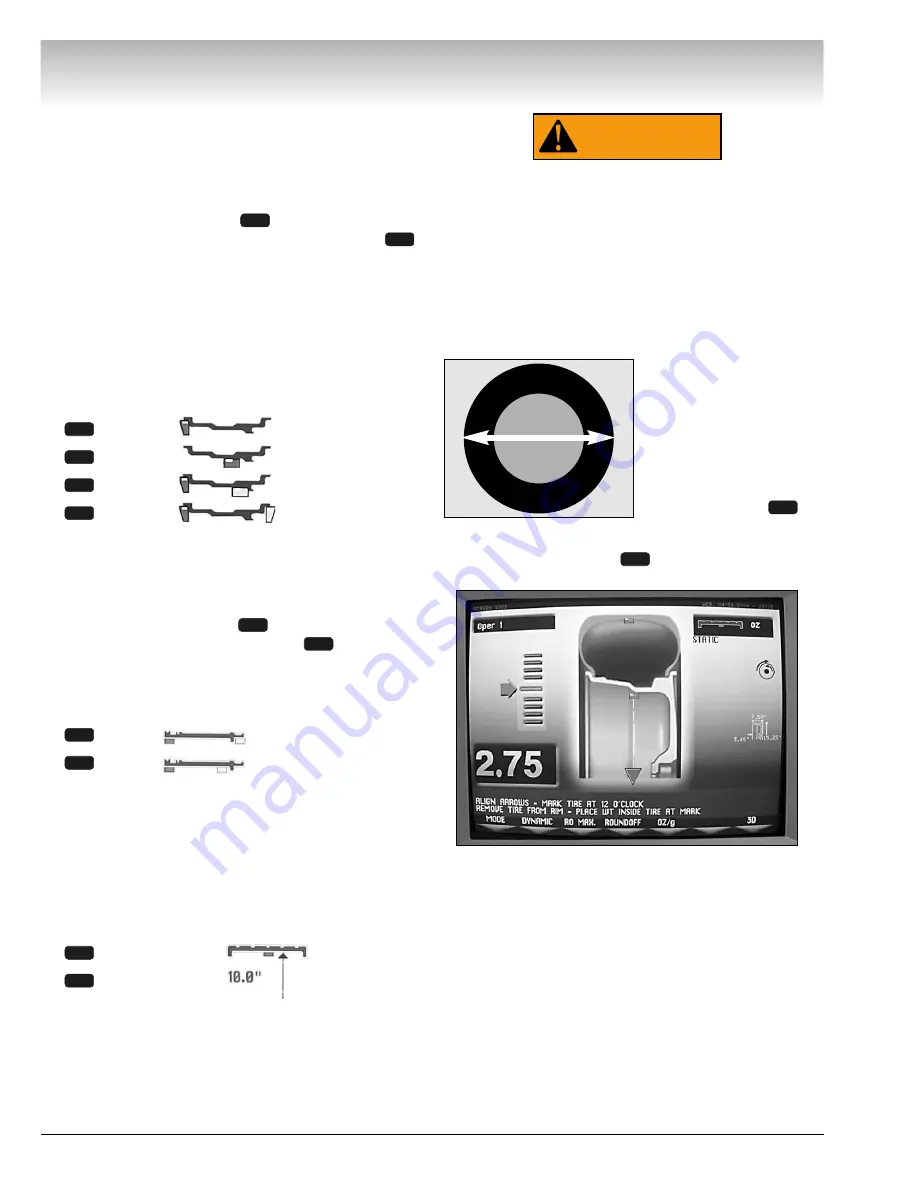

1.

Measure the out-

side tire diameter, see

figure 32, and enter this

diameter manually on

the patch menu screen,

DIAMETER option .

Figure 32 - Measure Outside Tire Diameter

2.

Select PATCH option

. The balancer automati-

cally sets itself for a STATIC balance.

Figure 33 - Patch Screen

3.

Move the offset arm tip to the inside of rim to set

tape-a-weight™ location. Wait for beep.

4.

Spin the wheel.

5.

Align the on-screen arrows. Next, mark the tire at

12 o’clock. Then remove the wheel assembly from the

machine.

6.

Disassemble the tire and rim. Place patch weight

in the tire at location marked on the tire. Reassemble

tire and rim matching the marks on the tire and rim.

7.

Complete by balancing the wheel assembly fol-

lowing normal procedures.

3

4

WARNING

4

3

2

1

7

1

4

3

2

1

6

1

18 •

Important: Always read and follow the on-screen operating instructions.

Video Balancer

Outside

Diameter