Model EEG-241, 242, 243, 244

61

Nov. 2014

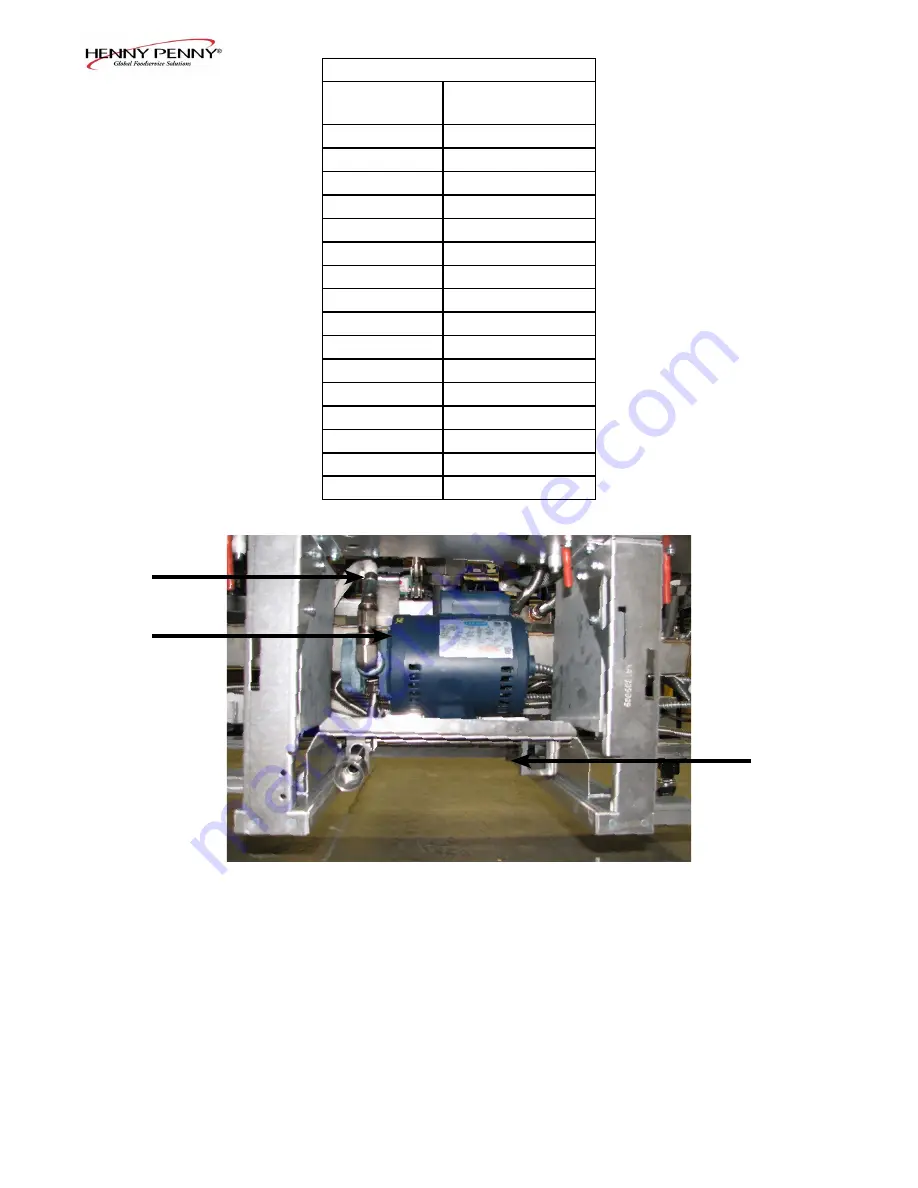

FLEX TUBE NUMBERS

Part Number

Flex Tube Length

(in.)

77523-001

12.0

77523-002

18.0

77523-003

24.0

77523-004

30.0

77523-005

36.0

77523-006

42.0

77523-007

48.0

77523-008

7.0

77523-009

13.0

77523-010

54.0

77523-011

10.0

77523-012

13.0

77523-013

14.0

77523-014

28.0

77523-015

32.0

77523-016

16.0

Recommend Parts: A=Truck Stock/B=Dist. Stock / *not shown/ A/R=As Required

1.

2.

3.

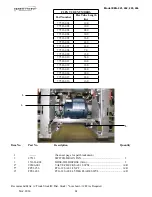

Item No.

Part No.

Description

Quantity

1

-------

(See next page for part breakdown)

2

87511

SWITCH-DRAIN PAN ........................................................... 1

3

151686-002

HOSE-OIL DISPOSE (34in) ................................................... 1

4*

90506-001

VALVE-CHECK SAE 12-3PSI ............................................... A/R

5*

FP01-256

FTG-12 SAE 1/2 NPT ............................................................. A/R

6*

FP01-283

FTG-12 SAE 8 45 DEG FLARE SWVL ................................. A/R

Summary of Contents for EVOLUTION ELITE EEG-241

Page 2: ......