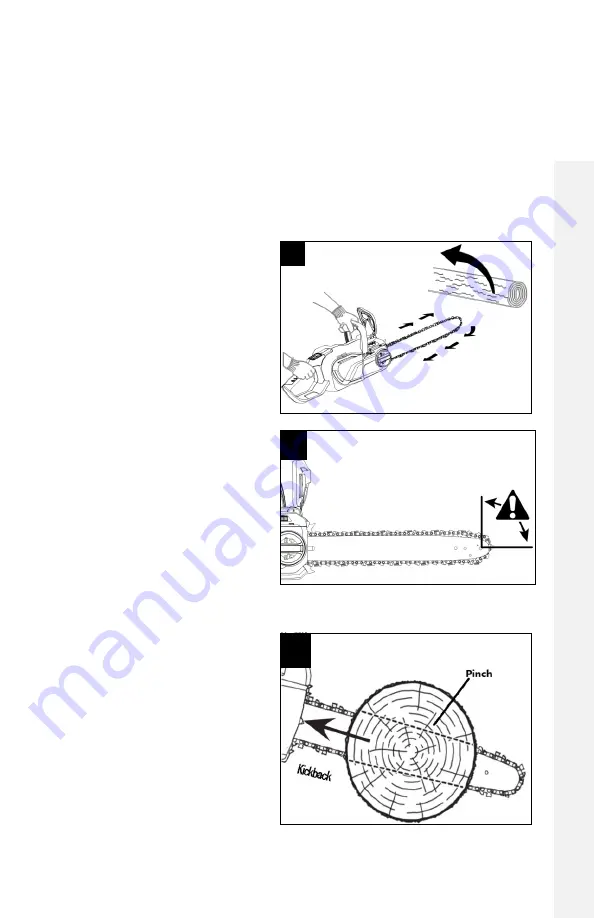

CAUSES AND OPERATOR

PREVENTION OF KICKBACK

(Fig. 1, 2, 3 & 4)

Kickback may occur when the nose or

tip of the guide bar touches an

object, or when the wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may cause a

sudden reverse reaction, kicking the

guide bar up and back towards he

operator.

Pinching the saw chain along the top of

the guide bar may push the guide bar

rapidly back towards the operator.

Either of these reactions may cause

you to lose control of the saw, which

could result in serious personal injury. Do

not rely exclusively upon the safety

devices built into your saw.

As a chain saw user, you should take

several steps to keep your cutting

jobs free from accident or injury.

Kickback is the result of tool

misuse and/or incorrect operating

procedures or conditions and can be

avoided by taking proper precautions as

given below:

3

1

Kickback

danger zone

2

Summary of Contents for A40LJ14B01

Page 1: ...40 Volt Cordless Chain Saw A40LJ14B01 A40LJ16B01 OPERATOR S MANUAL ...

Page 5: ...5 comply with ANSI Z87 1 ...

Page 20: ...20 ...

Page 33: ...33 Mounting Slot Guides the battery pack ...

Page 52: ...2ndCutUnderbuck 2 3Diameter toMeet 1stCut To Avoid Pinching ...

Page 58: ...37 Alignment Flange Tension Adjusting Pin 26b ...

Page 62: ...41 have the drive sprocket replaced by qualified service technician ...