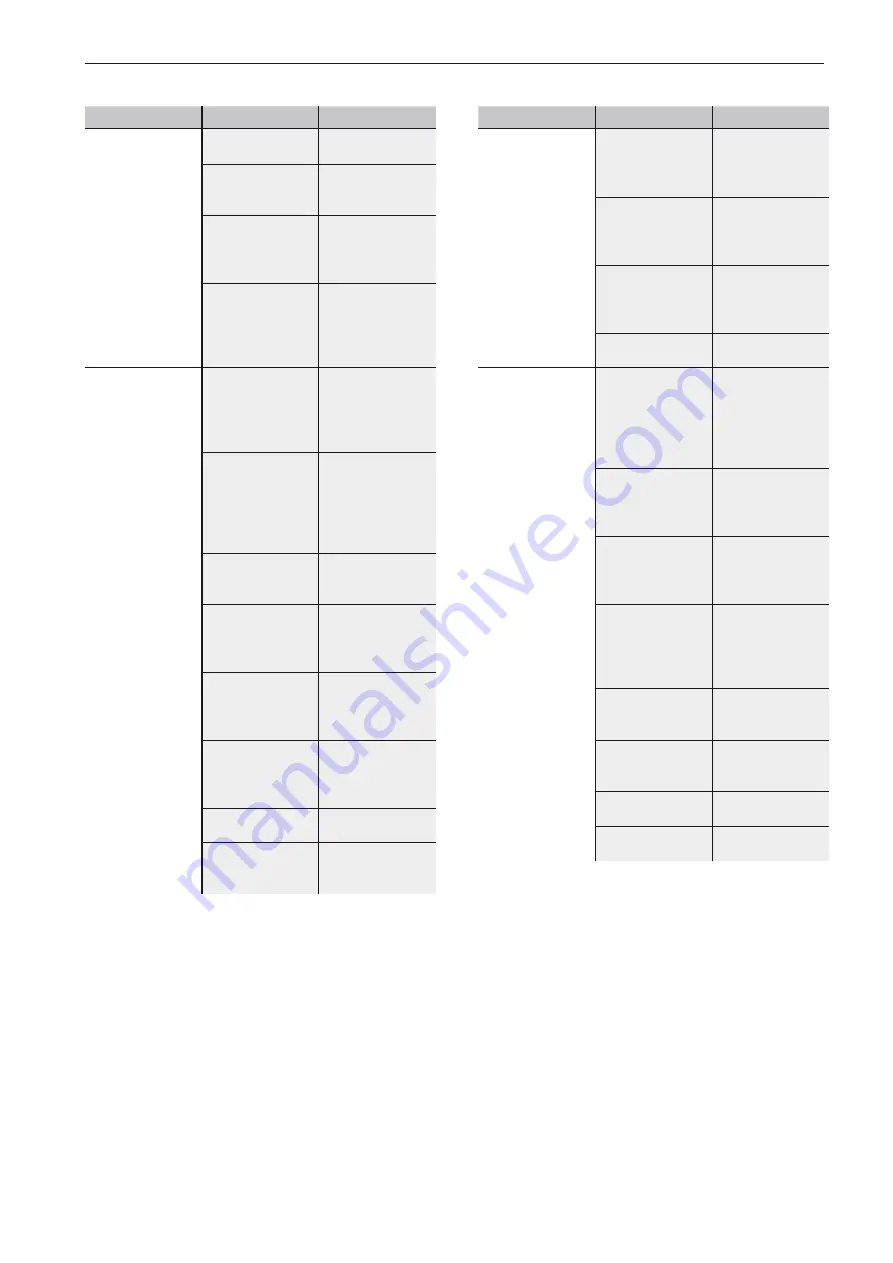

Disturbance / cause / trouble shooting

45

Disturbance

Cause

Trouble shooting

Pump vibrates or

makes a noise.

Anti-friction bear-

ing defective.

Exchange anti-

friction bearing.

Anti-friction bear-

ing not lubricated

properly.

Clean anti-friction

bearing and re-

lubricate.

Pump installed

under tension.

Connecting pipes

must be laid in

an unstressed

manner.

Cavitation

Check supply

for obstructions.

Check the duty

point and adjust if

necessary.

Pump runs but

immediately

switches off.

The motor circuit

breaker has been

triggered. Insuf-

ficient cooling of

the motor.

Provide adequate

motor cooling.

The motor circuit

breaker has been

triggered. Incor-

rect direction of

rotation of the

pump.

Check the direc-

tion of rotation.

Power input too

high.

Check the free

movement of the

pump.

Density of the

pumped medium

is too high.

Dilute the

pumped medium

or alter the proc-

ess.

Pump doesn't

operate in the

specified operat-

ing range.

Check the operat-

ing conditions.

An obstructed

pump has trig-

gered the motor

protection relay.

Check the free

movement of the

pump.

Pump switches

too often.

Observe operat-

ing mode.

Motor connected

incorrectly.

Connect motor to

correct operating

voltage.

Disturbance

Cause

Trouble shooting

Bearing becomes

hot

Bearing running

without lubrica-

tion:

lack of grease.

Top up grease,

replace bearing if

necessary.

Too much grease

in the bearing.

Remove surplus

grease until the

balls are just cov-

ered by grease.

Pump installed

under tension.

Connecting pipes

must be laid in

an unstressed

manner.

Anti-friction bear-

ing defective.

Exchange anti-

friction bearing.

Electric motor is

overly warm.

Incorrect direction

of rotation of the

pump.

Check the direc-

tion of rotation

and exchange

two phases to the

motor if neces-

sary.

Pump doesn't

operate in the

specified operat-

ing range.

Check the operat-

ing conditions.

Density of the

pumped medium

is too high.

Dilute the

pumped medium

or alter the proc-

ess.

Supply pipe and/

or impeller ob-

structed.

Clean the supply.

Remove any

sediment depos-

its from the pump/

pipeline.

Motor not power-

ful enough.

Replace motor

with a more pow-

erful model.

Motor connected

incorrectly.

Connect motor to

applicable operat-

ing voltage.

Coolant tempera-

ture > 40 °C.

Check ventilation

paths.

Pump switches

too often.

Observe operat-

ing mode.

Summary of Contents for herborner.X

Page 4: ......