Disassembly / assembly

52

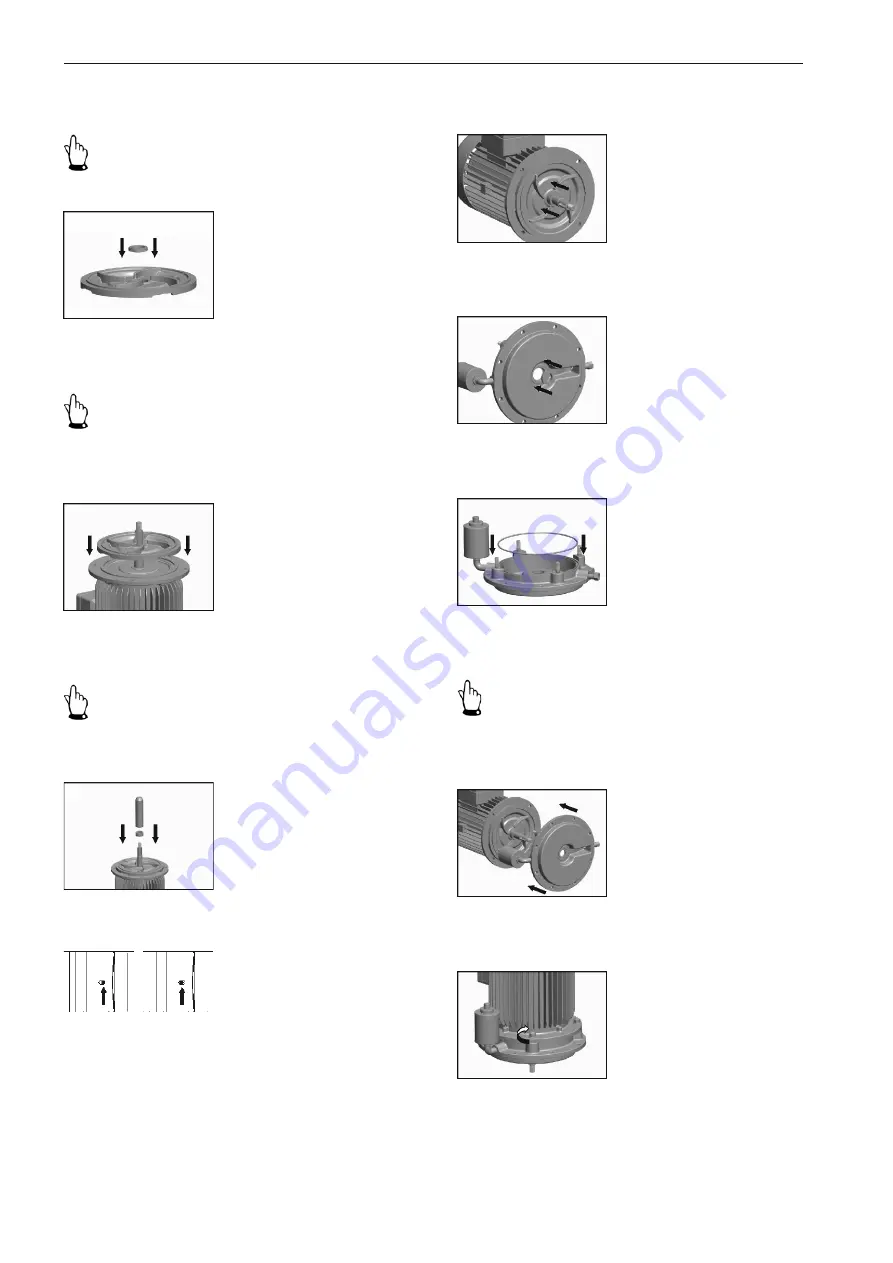

1.

Important!

For easy installation, lubricate O-rings with provided grease.

Press the counter ring with

the O-ring of the mechani-

cal seal (433.2) into the seal

cover (471) by hand.

2.

Important!

Do not damage the counter ring of the mechanical seal on

the thread and change-over of the motor shaft or press at

an angle!

Carefully slide the seal cover

(471) over the motor shaft

(819) and onto the centering

of the block motor (802).

3.

Important!

- Make sure you degrease the shaft surface!

- Comply with squareness tolerance of 0.1 mm!

Carefully slide the sliding

ring unit over the motor shaft

shoulder using an assembly

aid (accessories) and up to

the integrated counter ring.

Slide the sliding ring against

the counter ring until the pin

is centred.

Measure and adjust the

mounting dimension x (length

of sliding ring) at at least 3

different points.

Shaft Ø 20/24/28/30:

x = 19.1 mm

Shaft Ø 38/50:

x = 21.1 mm

Shaft Ø 55:

x = 22.1 mm

before

after

4.

Tighten the locking screw/s

on the mechanical seal

(433.2) using a hexagon

wrench.

5.

Press the counter ring with

the O-ring of the mechanical

seal (433.1) into the interme-

diate casing (113) by hand.

6.

Insert the O-ring (412) into

the groove on the intermedi-

ate casing (113).

7.

Important!

Do not damage the counter ring of the mechanical seal on

the thread and change-over of the motor shaft or press at

an angle!

Carefully slide the interme-

diate casing (113) over the

motor shaft (819).

8.

Screw the intermediate cas-

ing (113) to the block motor

(802).

Summary of Contents for herborner.X

Page 4: ......