Page 7

For technical questions, please call 1-888-866-5797.

Item 57719

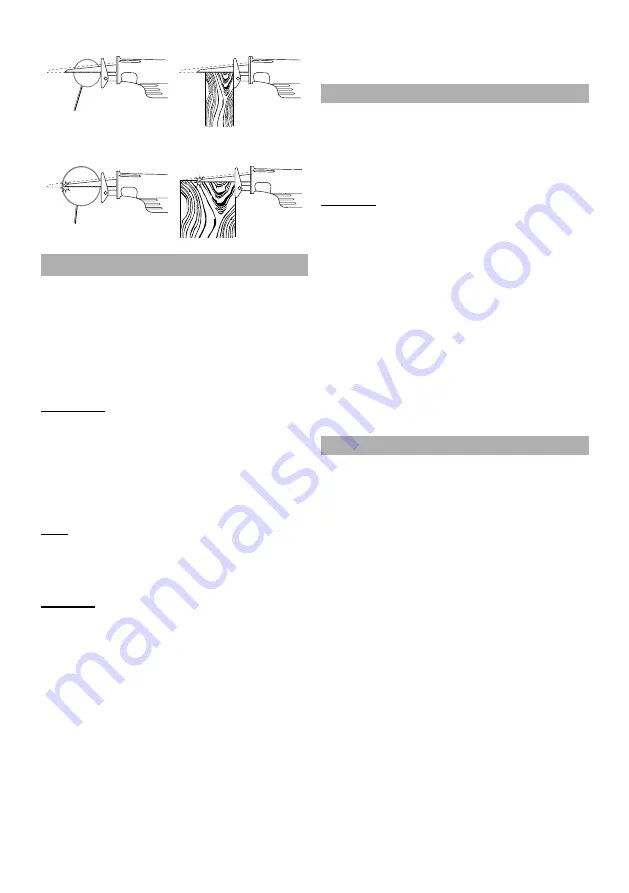

Workpieces that are Too Thick

PVC Pipe

Properly Sized Workpieces

PVC Pipe

General Operation

1. Push the Trigger Lock to the right to lock

Trigger, then insert a fully charged Battery

Pack into the base of the Saw, making sure

that it clicks into place securely. Be sure

the Battery Pack is securely seated into the

Handle so it does not fall off during use.

2. Grip Saw firmly with both hands, rest the

front of the Pivoting Shoe on workpiece

with the blade above the work.

IMPORTANT:

Do not start the Saw if the

Blade is in contact with anything.

3. Push Trigger Lock to the left, then press

Trigger to start the tool. The Work Light

will turn on when Trigger is pressed and

turn off when Trigger is released.

4. The tool has variable speed. To increase

speed, apply more pressure to Trigger. To

decrease speed, apply less pressure.

Note:

When cutting softer materials, use a faster speed.

When cutting harder materials, use a slower speed.

5. Allow the Saw to come up to full speed

before touching the workpiece.

6. Guide the saw blade into the workpiece.

WARNING! TO PREVENT SERIOUS INJURY:

Keep the Shoe pressed firmly against the

workpiece while cutting to prevent kickback.

7. Maintain a smooth motion, guiding the blade

through the material as it is cut. Follow the cut.

Do not press too hard. If the Saw slows down as

it is cutting, apply less pressure on the Saw.

8. To stop the Saw, release the Trigger.

9. Allow the Saw to come to a complete

stop before setting it down.

10. When finished using the Saw, push the

Trigger Lock to the right to lock Trigger.

11. To prevent accidents, remove Battery

Pack after use. Clean, then store the

Saw indoors out of children’s reach.

Plunge Cutting

Plunge cut into plywood, sheetrock, and thin

board panels.

Do not attempt to plunge cut

into thick, hard wood or metal panels.

1. Mark the cut line.

2. Place Pivoting Shoe on workpiece with blade parallel

to cut line, and NOT touching the workpiece.

WARNING!

To prevent serious injury due

to kickback, do not start a plunge cut with

the blade touching the workpiece

.

3. Push Trigger Lock to the left, then press Trigger.

4. Allow the saw to come up to full speed, then slowly

rotate saw on the Pivoting Shoe as the blade

contacts the workpiece. Hold the saw firmly.

5. Continue to slowly rotate the saw until the

blade has penetrated through the workpiece.

Press the Pivot Shoe firmly against the

workpiece and continue to make the cut.

6. To stop the saw, release the Trigger.

7. Allow the saw to come to a complete

stop before removing from cut.

8. To prevent accidents, remove Battery

Pack after use. Clean, then store the

Saw indoors out of children’s reach.

Metal Cutting

1. Install a metal cutting blade.

2. Coat the cutting surface with cutting oil to

prevent the blade from overheating.

3. Follow General Operation instructions above.