Example

Section No.

Page No.

Thank you for purchasing your new Hercules greenhouse. We recommend you familiarise yourself with the instructions

and read all safety information before you commence assembly. This instruction manual is also available online at

www.greenhousepeople.co.uk

in our technical help section should you need to reprint it. Should you require any addi-

tional advice you can always call us on 01782 388811.

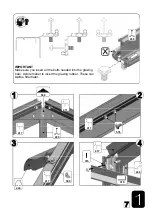

IMPORTANT:

PLEASE BE AWARE THAT THE YOUR GLAZING BARS (e.g. 916) / CORNER GLAZING BARS (e.g. 915) ALL NEED TO

HAVE RUBBER INSERTED INTO THEM BEFORE FRAME CONSTRUCTION CAN COMMENCE.

Safety Warning

Glass and aluminium can potentially cause injury. Please ensure you wear protective goggles, gloves, headgear and suitable

footwear when assembling and glazing the building.

Please remember that glass is fragile and should be handled with extreme care. Always clear up and dispose of any breakages

immediately.

Do not assemble the greenhouse in high winds.

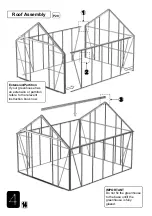

For safety reasons and ease of assembly, we recommend that this greenhouse is assembled by a minimum of two people.

Please clear all lying snow from the greenhouse roof as it can cause the roof to buckle or collapse.

Site Preparation

When selecting a site for your greenhouse, it is vital that you choose as flat and level an area as possible.

A concrete or slabbed base will provide the most solid foundation for your greenhouse.

Avoid placing your greenhouse under trees or in other vulnerable locations.

To minimise the risk of wind damage, try to select as sheltered a site as possible, e.g. beside a hedgerow or garden fence.

Additional Considerations

Please bear in mind that assembling your greenhouse can be time consuming. You may need to spread the construction over two

or more days. We recommend that you avoid leaving the building partially glazed. If you ever have to leave your greenhouse half

assembled and not anchored down, weigh it down with slabs or bags of sand to stop the wind moving it.

You will find it helpful to prepare a large, clean and clear area in which to work in. A garage floor or flat lawn area is ideal.

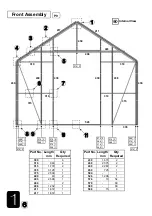

If you have arranged for someone to install your greenhouse for you, please check that all components are included. Most parts

are numbered and can be identified by a stamp or removable label. Alternatively, the components can be identified by lengths

detailed in the packing list (see diagram below).

Once installed your greenhouse requires little maintenance, but to maintain the smooth running of your door(s) WD40 or similar

can be applied to the door wheels and lower door guides.

Guarantee

Your new Hercules greenhouse is guaranteed for 10 years against faulty manufacture of the framework. This does not include

glass, moving parts, accidental damage or wind damage.

Look out for part

numbers

KEY

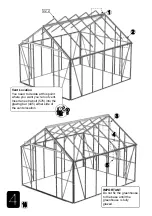

View Orientation

Potential Hazard

Wear safety

goggles

Wear gloves

Think/Decision

e.g.

Refer to section 4

Keep away

from water

while fitting

Cut/Trim

447

Summary of Contents for HE-NAS 10'5"x10'9"

Page 8: ...Section View 403 406 430 335 403 406 310 439 300 310 315 439 404 ...

Page 9: ...526 375 Section View 335 335 526 375 335 300 300 335 439 438 439 ...

Page 11: ...Internal Views 451 500 417 411 315 576 319 319 319 439 335 430 438 315 417 417 ...

Page 13: ...447 447 447 Internal View 300 447 303 303 ...

Page 15: ...430 335 300 450 430 411 411 417 500 ...

Page 18: ...445 Internal View ...

Page 26: ...XL Autovent Attachment to Hercules Greenhouses 709 543 541 540 541 Internal View 411 417 ...