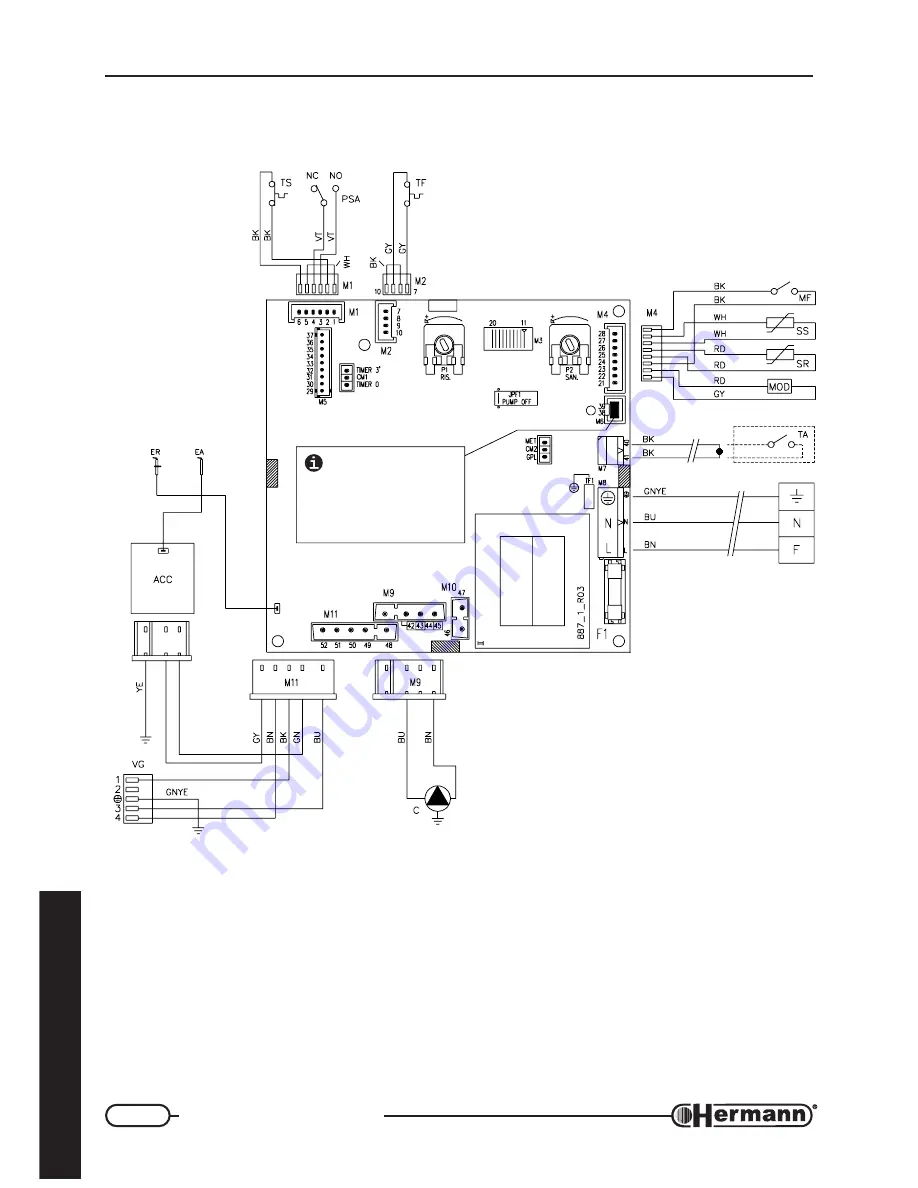

32

Regulation and servicing

for the technician

ACC Electronic igniter

C

Pump

EA

Ignition electrode

ER

Flame sense electrode

F1

Fuse (2 A)

MOD Modulator

MF

Priority flowstat

PSA Low water pressure switch

(contact NO closed = in pressure)

SR

NTC sensor, heating

SS

NTC sensor, DHW

TA

Voltage-free Contact for Room

Thermostat or Cronothermostat

(for trade) (safety extra low voltage

SELV)

TF

Flue thermostat

TS

Safety thermostat

VG

Gas valve (coils)

Electric diagram for

HABITAT 2 23 E

The contacts of the M6

connector must be

connected through a

jumper, otherwise the

boiler does not work in

the heating function

.

Colours

abbreviations:

BK

Black

BN

Brown

BU

Blue

GN

Green

GNYE

Green-Yellow

GY

Grey

OG

Orange

RD

Red

VT

Violet

WH

White