3

10

Program Controller RT100D

1. Introduction

The controller RT100D is used for controlling of electrical kilns for ceramics

and glas fireing.

The RT100D is able to control exactly the temperature and temperature

rate in a fireing process. Nine fixed programs are helpful for using this con-

trol unit. This programs can be adjusted individually. With this fixed pro-

grams the base of adjustment is already done for you.

Programdatas and values can be checked every time and set into the pro-

gram memory.

The control unit will be delivered with a wall pocket. For programming work

you can move the controller out of this pocket and if programming is done

you can put it back into the pocket. This feature makes it very easy to han-

dle the control unit.

IMPORTANT: It is

not allowed

to put the control unit

on the top of the kiln during fireing.

Every control unit RT100D is tested and checked for 100% of quality in our

company .

All our control units have an overheating safety relay ,but if you use the

control units you should observe the fireing .

Do not fire the kiln without observing.

If you have any problems please have a look into the error list at the end of

this manual.

If you are not able to solve your problems by yourself, please contact your

sales department.

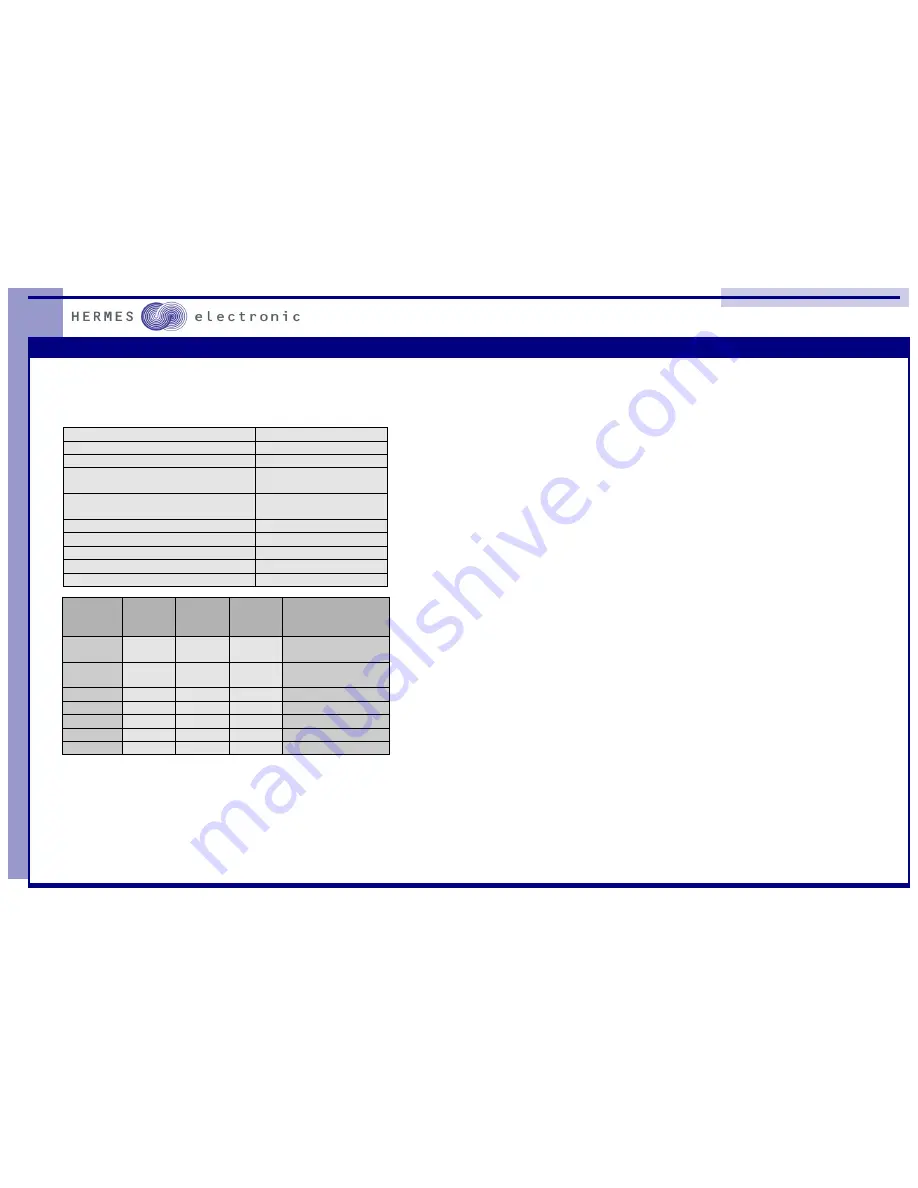

6.0 Technical Datas

* Using a Harting 7D connector the Pin-No. are not defined

Powerline

200 bis 250Volt 50 / 60Hz

Fuse

0,04 A T

Power consumption

2 VA

Output

2 Relais n.o.

230 V max. 4 A

Imput

Thermocouple Typ R

Pt10Rh / Pt

Solution

1 °C

Display

0,3 % +/- 1 Digit

Dimension

200 * 100 * 45 mm

Weight

0,6 kg

Ambient temperature

0 bis 50 °C

wire

No.

AMP

Pin-No.

Harting 7D

Pin-No.

Harting

15D

Pin-No.

Function

+ red

-white

1

2

3

4

B5

C5

Thermocouple Platin

+ green

-white

11

12

*

B5

A5

Thermocouple Nickel

1

8

5

A1

Input L1

2

9

2

B1

Input N

3

13

6

A3

Output heating

4

14

1

B3

Output N

7

7

7

C3

Output safety relay